Hi all,

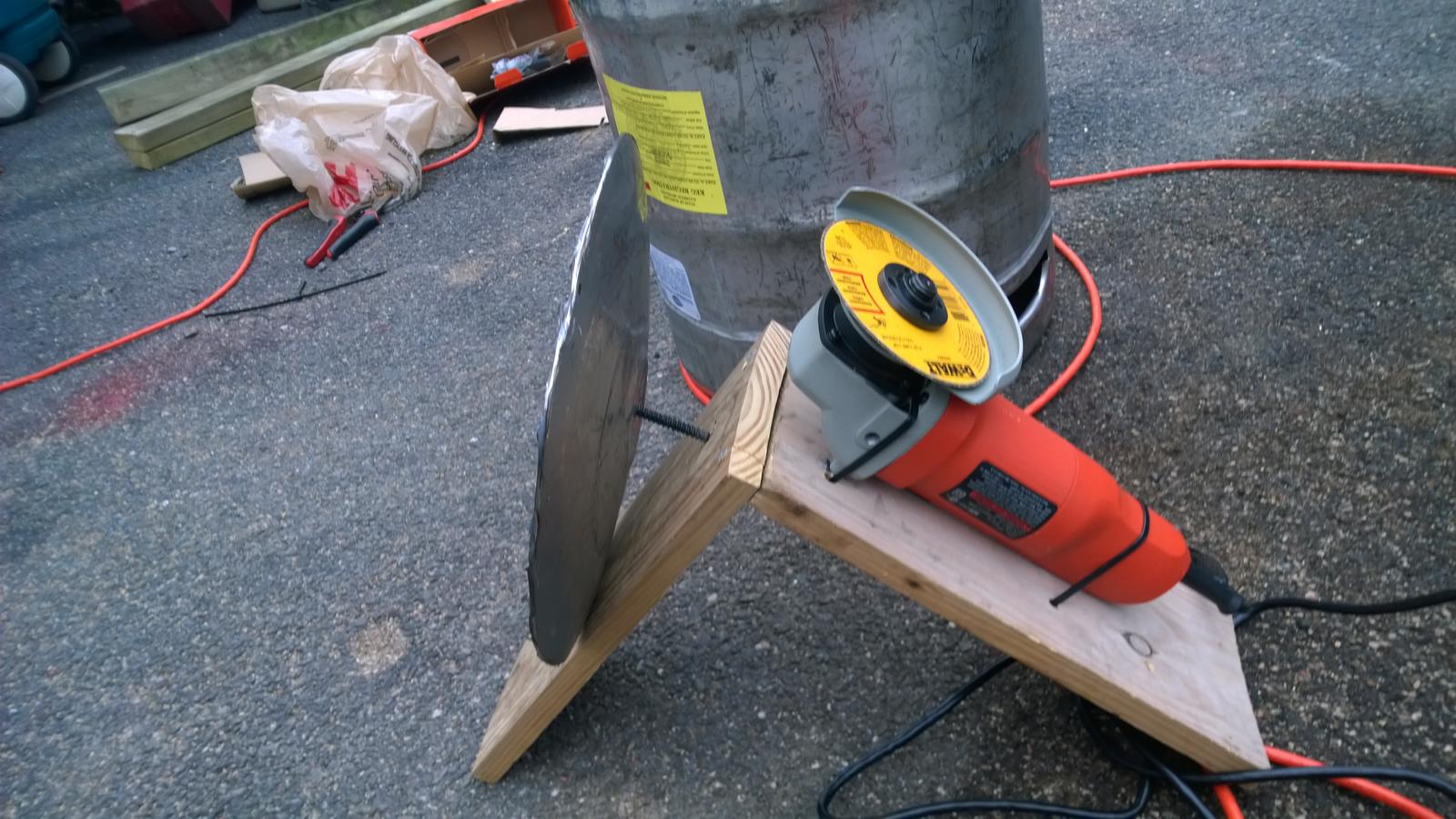

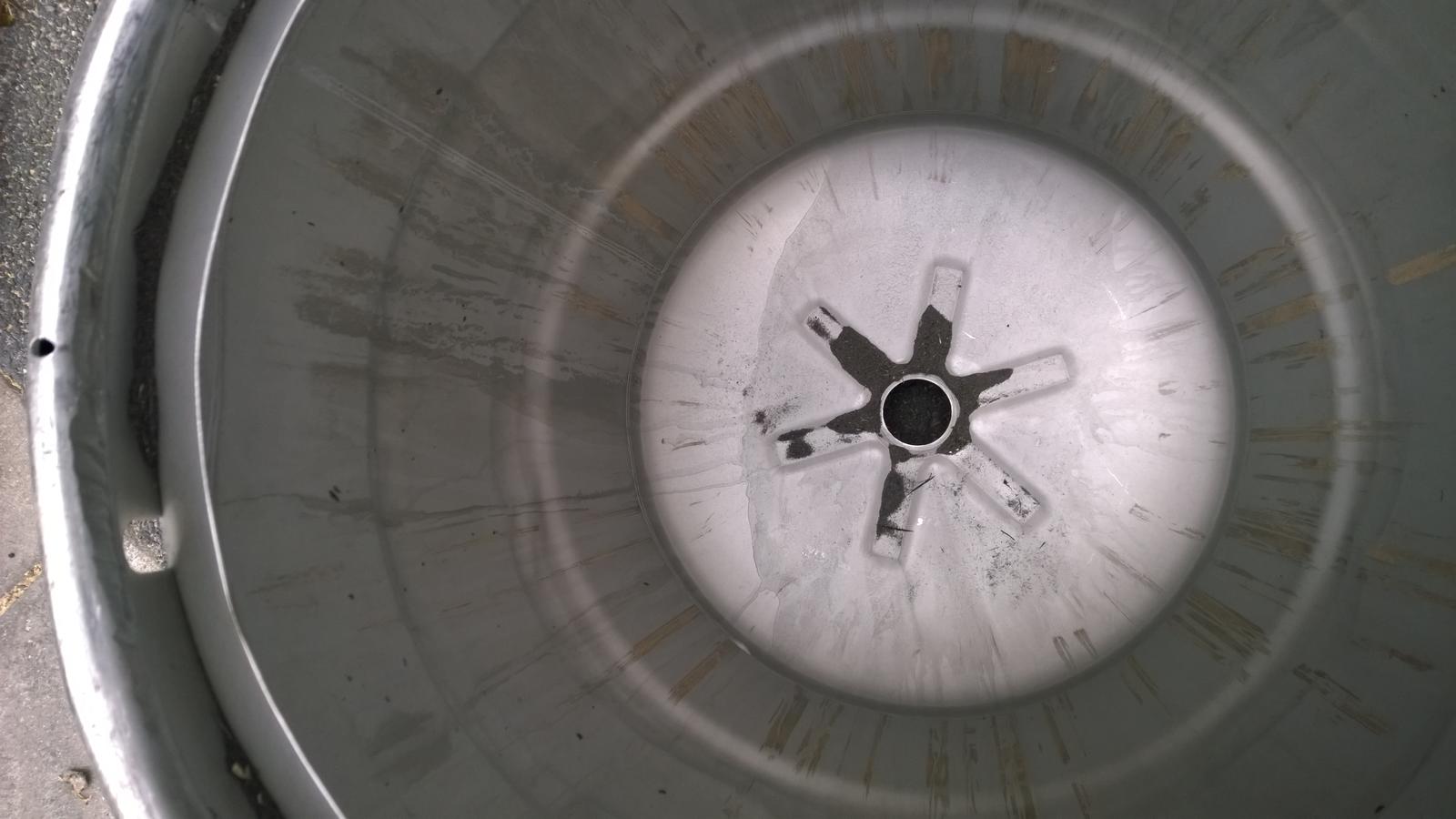

I'm setting up a recirculating E-HERMS with kegs that I have not yet cut. Been reading about flipping the MLT upside down and draining it through the keg top and putting a hole in the bottom instead and am considering doing that. If I'm going that route, is there any reason I wouldn't do the same thing for the HLT and BK to keep things consistent?

I'm setting up a recirculating E-HERMS with kegs that I have not yet cut. Been reading about flipping the MLT upside down and draining it through the keg top and putting a hole in the bottom instead and am considering doing that. If I'm going that route, is there any reason I wouldn't do the same thing for the HLT and BK to keep things consistent?