RPh_Guy

Bringing Sour Back

Nutrient generally isn't necessary for beer, but it doesn't hurt. I typically add a little.Your instructions don't mention a yeast nutrient. Is that an oversight? i.e. is yeast nutrient something that you do recommend?

Yep, sediment is normal.It leaves a sediment on the bottom. I'm guessing this is normal

Maximum souring!Are we planning to let it sour to the maximum amount? Or, is the plan to kill the lacto before it goes all the way to that extreme? Based on the directions given, I'm guessing the former rather than the latter.

If this turns out too sour for you but otherwise good, next time you can add some dry hops 12-24 hours after the Lacto. Czech Saaz, Strisselspalt, or Amarillo would be really nice imo.

Hops prevent Lacto from souring.

I wanted to make things simple, but I would actually pitch the Lacto about 6-8 hours after the yeast.I'll be doing one of the batches according to rph_guy's directions (above). However, in case I need to troubleshoot, I'll be holding off on adding the lacto to the other two. I intend for them to be backups in case I somehow botch the first batch.

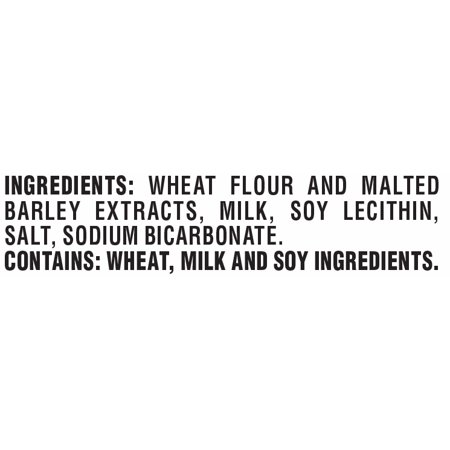

Few thoughts:I just checked on my lacto thermos. The temperature dropped from 100 to 88 overnight, which should be fine. The wort still smells and tastes sweet; there's no acid at all. Shirley it should be sour by now! Is it possible the grain I added had no bugs in it? I used pale ale malt, just because it's the freshest. My 2-row is over a year old and the pilsner is 2 or 3 years old.

I should probably boil it again, strain it, and add 2-row or pils (why not both?) because they weren't kilned as high.

1. Ideally you want to maintain high temperature. Maybe a water bath would help, especially if you have anything that could apply heat.

2. It is difficult to taste acid in unfermented wort because the sweetness covers it. Testing pH is more reliable (with a meter).

3. Wild cultures are unpredictable, but I think it's pretty unlikely you had sterile grain. Maybe it just needs more time. I would not boil it again, just add more grain if you don't have any activity.

Consider getting a source of L. plantarum. It really is the best for a number of reasons.

Cheers

Last edited: