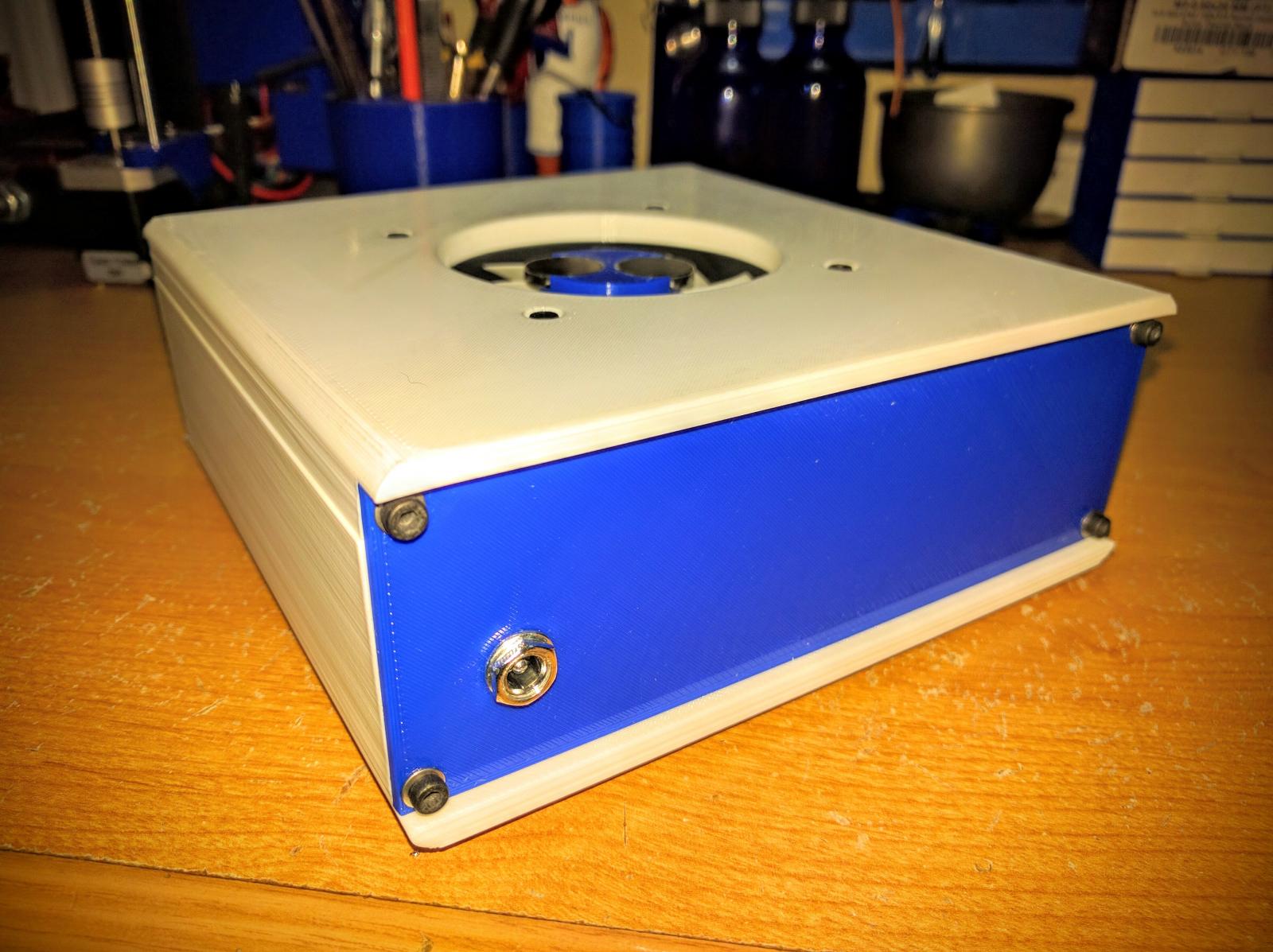

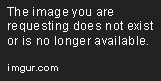

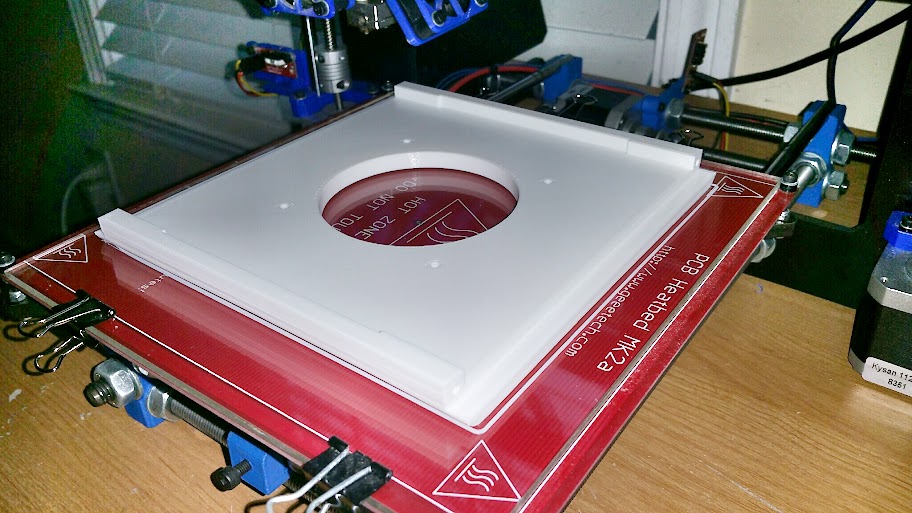

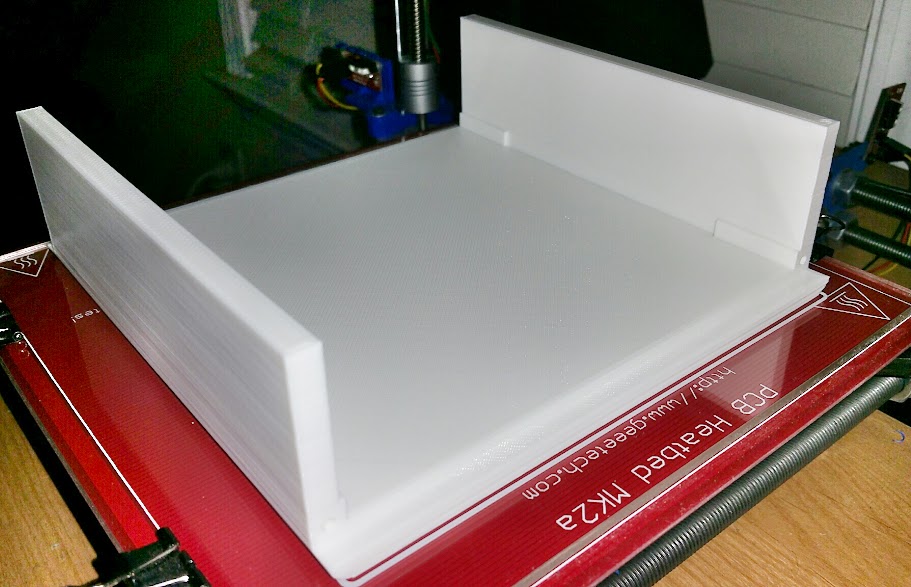

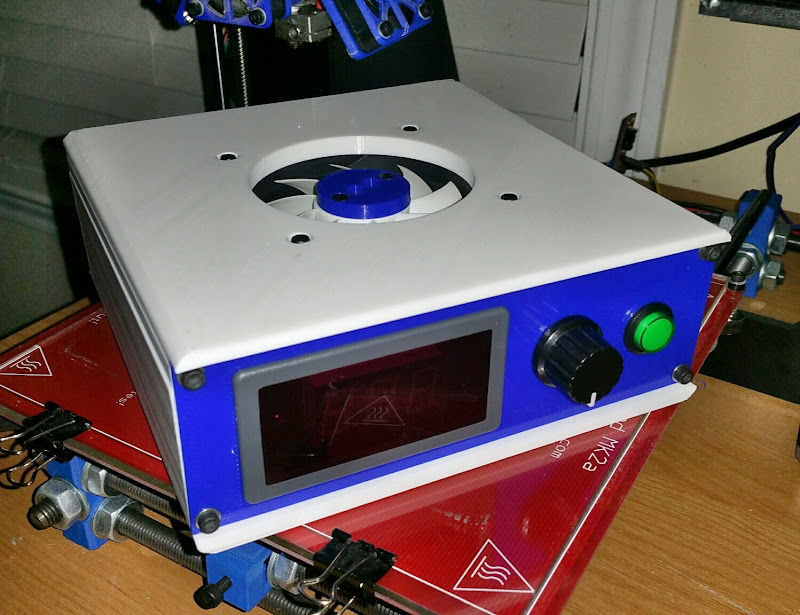

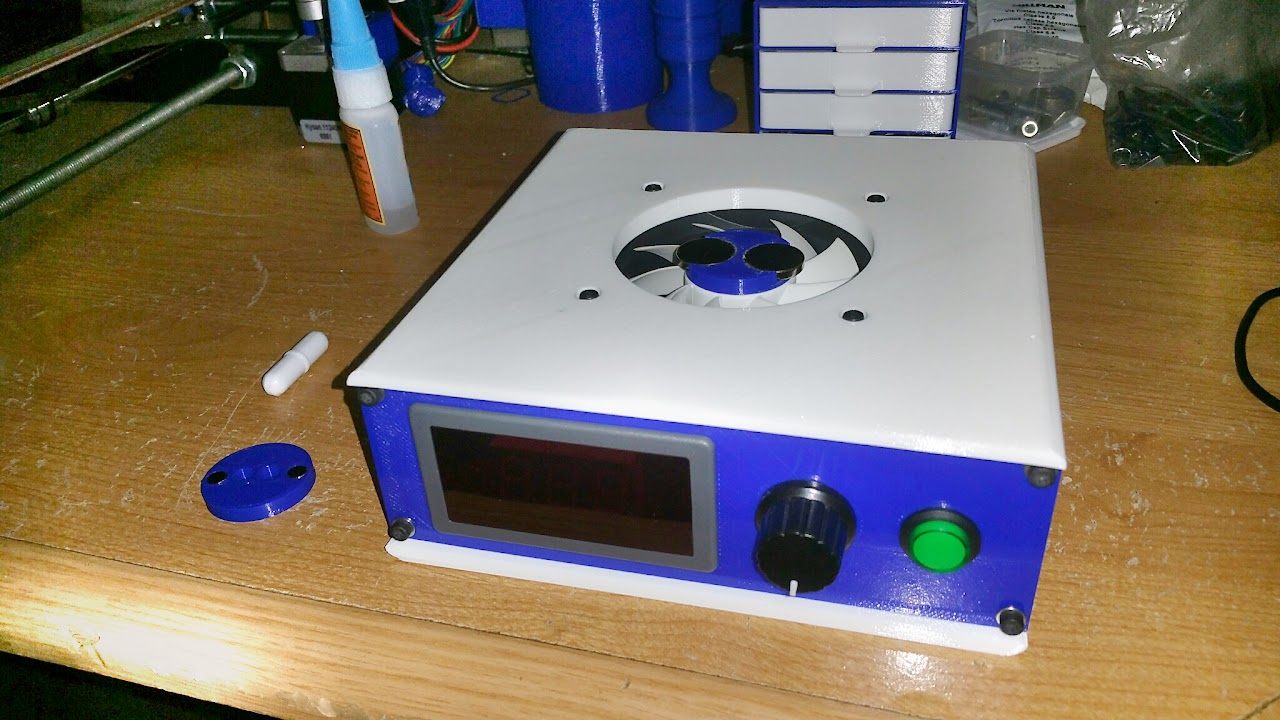

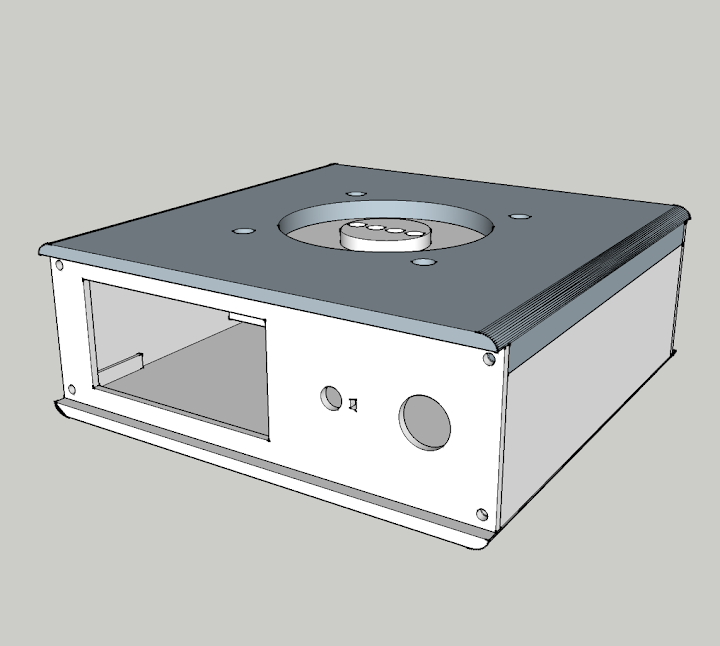

I have seen some 3d printed stir plates floating around so I figured I would make my own rendition by remixing my stc1000 enclosure.

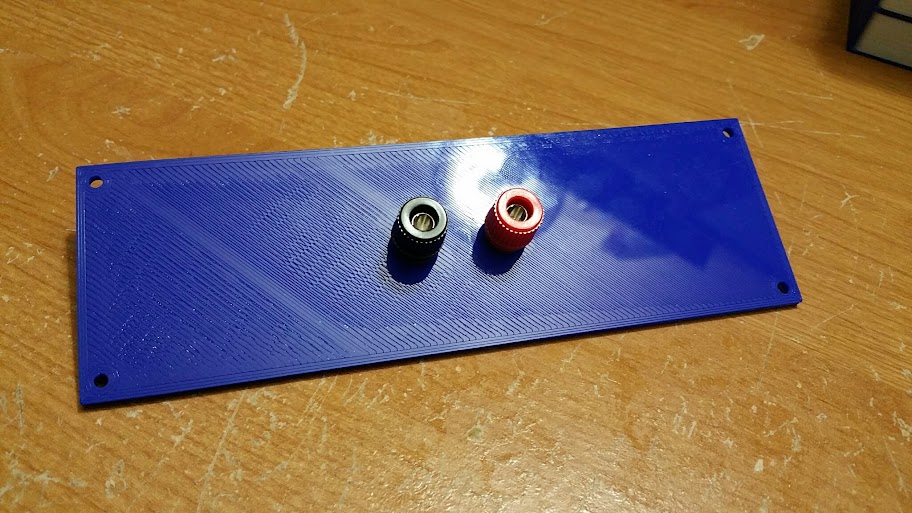

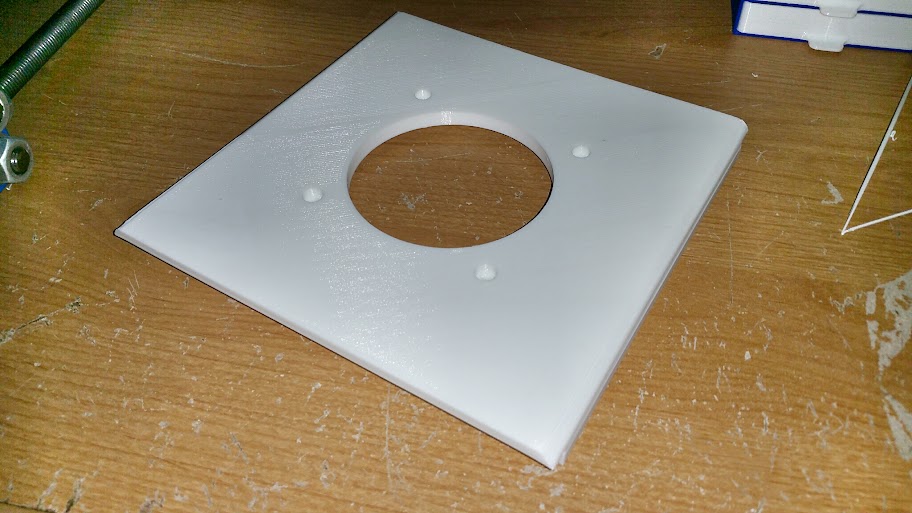

I used an 80mm fan, pwm speed controller, and some little .7" x .11" neo magnets.

Upgraded magnets

And I shall call it... R2...

Test Video:

[ame]https://www.youtube.com/watch?v=ZQPAgM_KiDU[/ame]

--------------------------------

Files: http://www.thingiverse.com/thing:1413550

Fan: http://www.amazon.com/gp/product/B00H3SWJ24/?tag=skimlinks_replacement-20

Controller: http://www.ebay.com/itm/141645156384

Magnets: http://www.homedepot.com/p/MASTER-M...rth-Magnet-Discs-3-per-Pack-07047HD/202526369

Stir Bar Kit: http://www.amazon.com/gp/product/B01A60XJBU/?tag=skimlinks_replacement-20

5L Flask: http://www.amazon.com/gp/product/B006UKI9X4/?tag=skimlinks_replacement-20

I used M3 x 40mm socket cap machine screws, nuts, and washer for the fan, and M3 x 22 socket cap machine screws and washers to mount the front and rear plates.

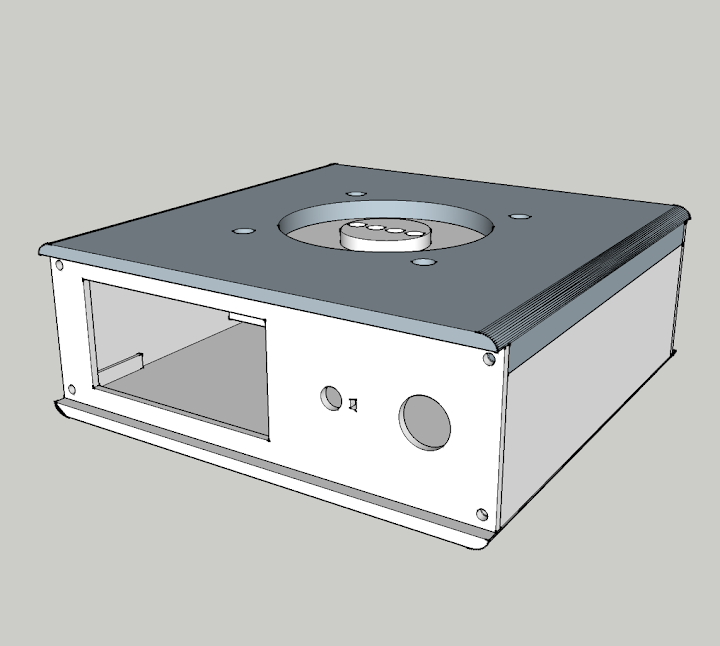

I personally used binding posts in the rear plate to connect some little banana plug leads to my bench top PSU. Feel free to request any kind of changes to the rear plate for various power options, or the front plate for different types of controllers and displays.

--------------------------------

CHANGELOG:

3/12/2016 - The stir plate is complete and I have tested to make sure the fan works, etc... but I have not tested it out with a erlenmeyer flask, stir bar, and liquids yet. My flask should arrive weds., and I will upload video of the test (and more pics) when complete.

3/17/2016 - I got my 5L flask in today and tested the stir plate. The magnets I was using were too small, at least for my biggest stir bar. It kept throwing the bar to the outside. I ran to home depot and bought some .7" DIA x .11" thick rare earth super magnets and remixed my magnet puck. I still had issues with the biggest stir bar, but then I tried the second largest stir bar and it worked extremely well. I got a decent vortext at 25% on the PWM controller, and it just got better all the way up to 100%. I also added some little rubber feet to the bottom of the stir plate for vibration dampening. I would also like to note that I didnt even glue the magnet puck to the fan. The magnets are strong enough to stick to the fan magnetically.

I used an 80mm fan, pwm speed controller, and some little .7" x .11" neo magnets.

Upgraded magnets

And I shall call it... R2...

Test Video:

[ame]https://www.youtube.com/watch?v=ZQPAgM_KiDU[/ame]

--------------------------------

Files: http://www.thingiverse.com/thing:1413550

Fan: http://www.amazon.com/gp/product/B00H3SWJ24/?tag=skimlinks_replacement-20

Controller: http://www.ebay.com/itm/141645156384

Magnets: http://www.homedepot.com/p/MASTER-M...rth-Magnet-Discs-3-per-Pack-07047HD/202526369

Stir Bar Kit: http://www.amazon.com/gp/product/B01A60XJBU/?tag=skimlinks_replacement-20

5L Flask: http://www.amazon.com/gp/product/B006UKI9X4/?tag=skimlinks_replacement-20

I used M3 x 40mm socket cap machine screws, nuts, and washer for the fan, and M3 x 22 socket cap machine screws and washers to mount the front and rear plates.

I personally used binding posts in the rear plate to connect some little banana plug leads to my bench top PSU. Feel free to request any kind of changes to the rear plate for various power options, or the front plate for different types of controllers and displays.

--------------------------------

CHANGELOG:

3/12/2016 - The stir plate is complete and I have tested to make sure the fan works, etc... but I have not tested it out with a erlenmeyer flask, stir bar, and liquids yet. My flask should arrive weds., and I will upload video of the test (and more pics) when complete.

3/17/2016 - I got my 5L flask in today and tested the stir plate. The magnets I was using were too small, at least for my biggest stir bar. It kept throwing the bar to the outside. I ran to home depot and bought some .7" DIA x .11" thick rare earth super magnets and remixed my magnet puck. I still had issues with the biggest stir bar, but then I tried the second largest stir bar and it worked extremely well. I got a decent vortext at 25% on the PWM controller, and it just got better all the way up to 100%. I also added some little rubber feet to the bottom of the stir plate for vibration dampening. I would also like to note that I didnt even glue the magnet puck to the fan. The magnets are strong enough to stick to the fan magnetically.

Last edited by a moderator: