Hello All

I have recently been thinking about upgrading my equipment to accommodate 10 gallon batches. I currently brew in my garage using a propane fish cooker. This has been working just fine, but I find that I mostly brew during the winter time and I really want to be able to brew with the door closed. So with those 2 "wants" in mind, I have decided to start slowly putting together an electric brewery.

This thread will most likely be just a place to store my thoughts for now since I can't afford to fully jump into this right away (according to my wife). But once I start, I will try to keep a build update thing going. I have always wanted to do that!

My goal for this brewery is to be able to brew 10 gallon batches, use only electricity for heat source, keep costs low, and keep design simple. I am planning to do this without any pumps right away. I am going to design my system to be able to be upgraded easily in the future to the max of what I will need. I know that I will not be wanting to brew more than 10 gallon batches on this system.

I currently have 3 15.5 gallon kegs sitting around, so I plan to use them. I really only want to use 2 though. One for my HLT and one for my BK.

I have a 10 gallon cooler mash tun with false bottom that I LOVE. I have had great results with it even in cold weather. According to a chart I saw from Bobby, I should be able to brew up to 1.060 OG batches in the cooler at 10 gallon batches (1.25qts/gal). I don't plan on ever wanting to brew a 10 gal batch of big beer. I generally brew beers that top out around 1.060 at this point anyways, its the beer that I enjoy most!

So I have started sort of a parts list/to do list/idea list/dream list, I really like lists.

Garage Upgrades I will need/want to do a few things in the garage to make this possible.

-Brew Stand. I need to build some sort of brew stand to hold everything. This thing will most likely be designed last, so I can brew a few times on some tables I have to so I can decide which permanent stand configuration I would want.

-Edited 2/2/15 Electrical Supply. I will be adding a 30amp 240v outlet in my garage. Decided I just want to run one 5500watt element at a time. My utility room shares a wall with the garage so the wire running should be quite simple. Plan to put a 30A240V non-gfci breaker in the panel. Run 10/3 wire from breaker. 30A outlet in garage. 50A spa panel (possibly incorp'd in control panel?) wired to a 30A plug that plugs in outlet. I will be GFCI protected.

-Throwing around the idea of adding a drain in the garage somehow for a sink so that I can chill in the garage (already have tap in garage) and wash in a utility sink that I could add too.

-Vent hood? Would this be necessary? My garage is a tuck-under style and is below my master bedroom and is fully insulated. I would think I would want to add a vent hood??

Brew Items The good stuff!

HLT

-Make out of Keg

-4500w element DIY

-Some sort of temp probe

-Valve

-Sight gauge

Boil Kettle

-Make out of keg

-5500w element DIY

-Valve

-Sight gauge (would this be a bad idea on a BK? I really want one on it to hit my volumes better)

-Analog temp probe to monitor cooling progress

Mash Tun

-Plan to keep using my 10 gallon cooler with false bottom. Love it, and I have been getting real good at keeping temps on it.

-This is where I plan to save alot of money. Not doing a HERMS system, at least right now (but will be able to upgrade later if I really want, but not wanted right now). I will not need to buy herms coil, pumps, etc for this.

-Temp probe.

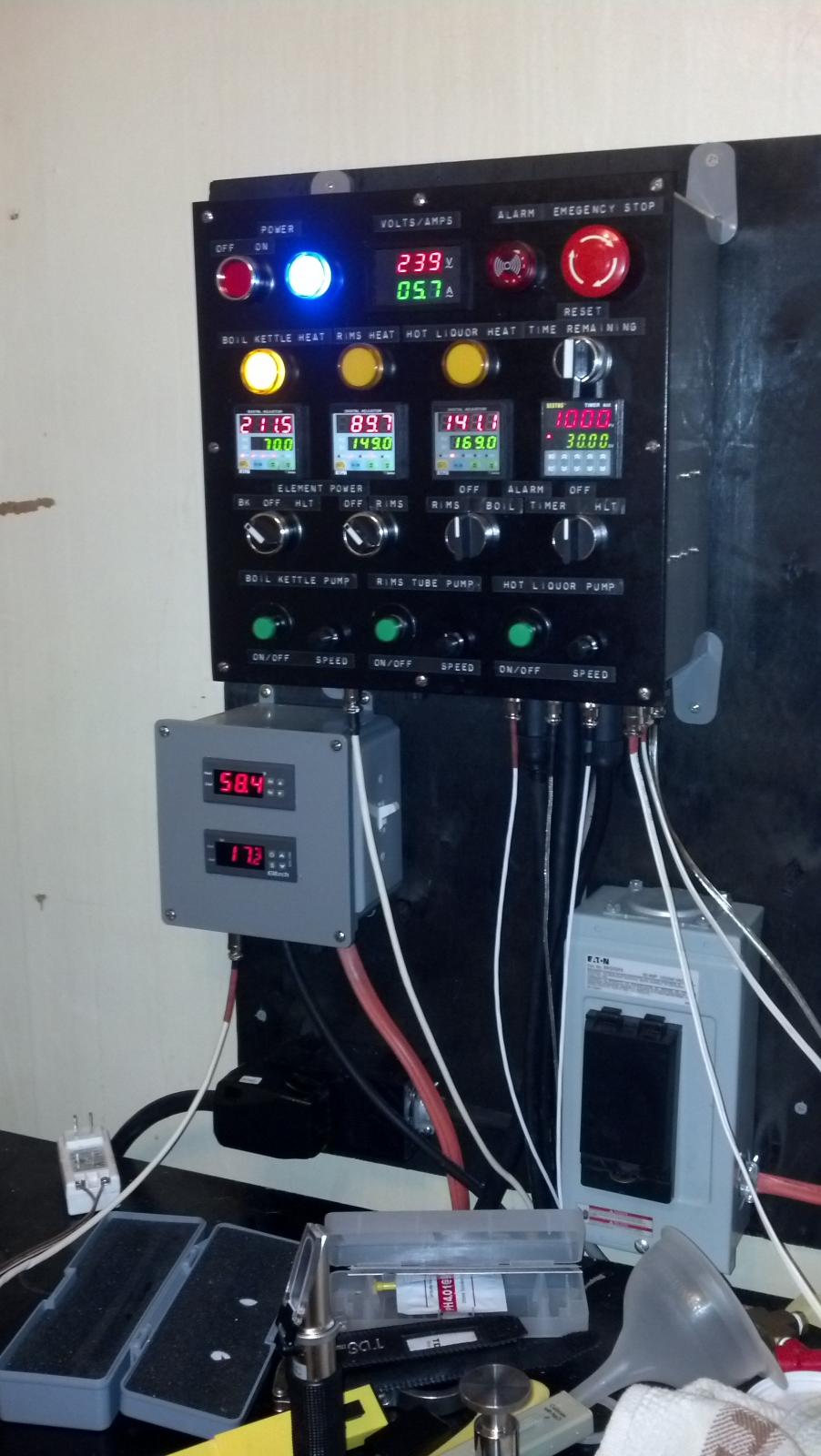

Control Panel

-Going to be similar to this wiring diagram. I will be adding a plug port for the RTD sensor though, so I can switch which RTD the PID will read.

MISC

-Wanting to incorporate a RO system so I can stop buying 9 gallons of DI water every brew day

I will add to this post as things progress and as my plans change, which they will a million times I am sure!

I apologize for the lengthy read, but I like putting my thoughts to paper (or the web I guess?).

If anyone has any comments or suggestions feel free to let me know! Otherwise just wish me luck on this endeavor!

I have recently been thinking about upgrading my equipment to accommodate 10 gallon batches. I currently brew in my garage using a propane fish cooker. This has been working just fine, but I find that I mostly brew during the winter time and I really want to be able to brew with the door closed. So with those 2 "wants" in mind, I have decided to start slowly putting together an electric brewery.

This thread will most likely be just a place to store my thoughts for now since I can't afford to fully jump into this right away (according to my wife). But once I start, I will try to keep a build update thing going. I have always wanted to do that!

My goal for this brewery is to be able to brew 10 gallon batches, use only electricity for heat source, keep costs low, and keep design simple. I am planning to do this without any pumps right away. I am going to design my system to be able to be upgraded easily in the future to the max of what I will need. I know that I will not be wanting to brew more than 10 gallon batches on this system.

I currently have 3 15.5 gallon kegs sitting around, so I plan to use them. I really only want to use 2 though. One for my HLT and one for my BK.

I have a 10 gallon cooler mash tun with false bottom that I LOVE. I have had great results with it even in cold weather. According to a chart I saw from Bobby, I should be able to brew up to 1.060 OG batches in the cooler at 10 gallon batches (1.25qts/gal). I don't plan on ever wanting to brew a 10 gal batch of big beer. I generally brew beers that top out around 1.060 at this point anyways, its the beer that I enjoy most!

So I have started sort of a parts list/to do list/idea list/dream list, I really like lists.

Garage Upgrades I will need/want to do a few things in the garage to make this possible.

-Brew Stand. I need to build some sort of brew stand to hold everything. This thing will most likely be designed last, so I can brew a few times on some tables I have to so I can decide which permanent stand configuration I would want.

-Edited 2/2/15 Electrical Supply. I will be adding a 30amp 240v outlet in my garage. Decided I just want to run one 5500watt element at a time. My utility room shares a wall with the garage so the wire running should be quite simple. Plan to put a 30A240V non-gfci breaker in the panel. Run 10/3 wire from breaker. 30A outlet in garage. 50A spa panel (possibly incorp'd in control panel?) wired to a 30A plug that plugs in outlet. I will be GFCI protected.

-Throwing around the idea of adding a drain in the garage somehow for a sink so that I can chill in the garage (already have tap in garage) and wash in a utility sink that I could add too.

-Vent hood? Would this be necessary? My garage is a tuck-under style and is below my master bedroom and is fully insulated. I would think I would want to add a vent hood??

Brew Items The good stuff!

HLT

-Make out of Keg

-4500w element DIY

-Some sort of temp probe

-Valve

-Sight gauge

Boil Kettle

-Make out of keg

-5500w element DIY

-Valve

-Sight gauge (would this be a bad idea on a BK? I really want one on it to hit my volumes better)

-Analog temp probe to monitor cooling progress

Mash Tun

-Plan to keep using my 10 gallon cooler with false bottom. Love it, and I have been getting real good at keeping temps on it.

-This is where I plan to save alot of money. Not doing a HERMS system, at least right now (but will be able to upgrade later if I really want, but not wanted right now). I will not need to buy herms coil, pumps, etc for this.

-Temp probe.

Control Panel

-Going to be similar to this wiring diagram. I will be adding a plug port for the RTD sensor though, so I can switch which RTD the PID will read.

MISC

-Wanting to incorporate a RO system so I can stop buying 9 gallons of DI water every brew day

I will add to this post as things progress and as my plans change, which they will a million times I am sure!

I apologize for the lengthy read, but I like putting my thoughts to paper (or the web I guess?).

If anyone has any comments or suggestions feel free to let me know! Otherwise just wish me luck on this endeavor!