jeffceo24

Active Member

- Joined

- Feb 5, 2018

- Messages

- 30

- Reaction score

- 2

Hey Guys,

I'm making the switch to BIAB from extract. I live in southern New England and have well water. My profile is (in PPM/mg/L):

Calcium: 8.5

Magnesium: 2

Sodium: 5.4

Chloride: 12.2

Sulfate: 8

Alkalinity (CaCO3): 25

PH: 5.9

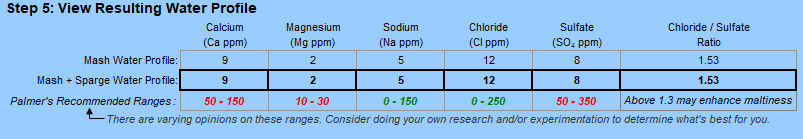

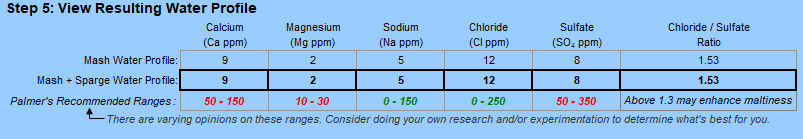

I will primarily be brewing IPAs and NEIPAs. I am expecting to start with around 7.2 gallons for a 10LB grain bill. I have been using the EZ Water Calculator spreadsheet but they give wide ranges. Does anyone have any advice for me? Thank you!

I'm making the switch to BIAB from extract. I live in southern New England and have well water. My profile is (in PPM/mg/L):

Calcium: 8.5

Magnesium: 2

Sodium: 5.4

Chloride: 12.2

Sulfate: 8

Alkalinity (CaCO3): 25

PH: 5.9

I will primarily be brewing IPAs and NEIPAs. I am expecting to start with around 7.2 gallons for a 10LB grain bill. I have been using the EZ Water Calculator spreadsheet but they give wide ranges. Does anyone have any advice for me? Thank you!