Multiple - OFFICIAL Kate the Great Russian Imperial Stout Clone

--------------------------------------------------------------------------------

Recipe Type: All Grain

Yeast: WLP001 or Wyeast 1056

Yeast Starter: Yes

Batch Size (Gallons): 5

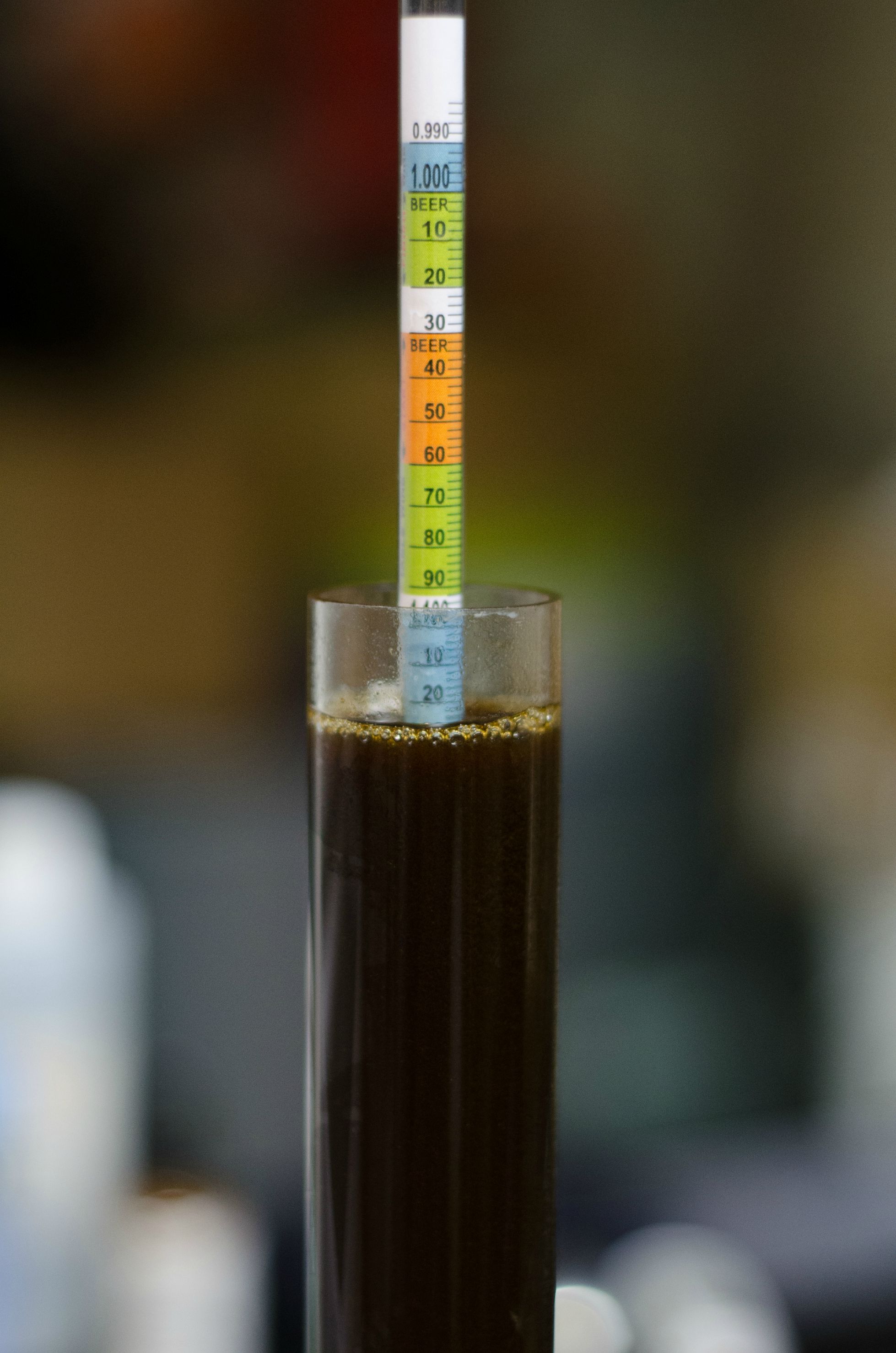

Original Gravity: 1.104

Final Gravity: 1.028

Boiling Time (Minutes): 75

Primary Fermentation (# of Days & Temp): 3 weeks @ 68F

Secondary Fermentation (# of Days & Temp): 5-6 months

Tasting Notes: Have not brewed this yet, but the reputation speaks for itself.

Here's what Todd Mott, Head Brewer, from The Portsmouth Brewery sent me:

" I will give you #s for a full mash and a partial mash, since it is pretty much impossible to brew Kate with an all extract recipe.

When we brew a batch of Kate we use 77% Pale malt, 2% Crystal 45, 1% Caramel 120, 1% Chocolate malt,1% Black malt, 3% Carafa DH# 3 (Weyerman),3.5% Wheat malt 3.5% Flaked Barley, 2% Roasted malt,3.5% Special B, 2.5% Aromatic. We dough in at 166 to stabilize the mash at 149 degrees F. Saccrification rest for 45 min. or until conversion occurs. Vorlauff (recirculate) 'til clarified and run off. Collect about 1/3rd of your wort and sparge to collect 6.5 gals (for a 5 gal. yield) at 26 degrees Plato or 1.104 degrees Specific Gravity. Yea it's big.... but we like it like that!! (So you are going to need to use your mash tun efficiency to figure out how many pounds of malt you are going to need in total. But to tell you the truth when you get to this thick of a mash your efficiency is going to drop 3-4%).

Boil the wort for 5 mins. for the hot break and then add your bittering hops for 75 mins. We bitter at 38 IBUs with Magnum, 10 IBUs with Styrian Golding and 15 IBUs with Perle. This is the bittering addition. We add a flavor addition for 15 mins with Centennial for 2 IBUS. Our final addition of Palisade, Styrian Golding and Willamette account for about 3 more IBUs at whirlpool. Cool wort and pitch a good amount of White labs WLP 001 or Wyeast 1056 and ferment til it is done. Put into conditioning for about 5 or 6 months and you'll have an amazing imperial stout.

Now, if you brew a partial mash, use 9#s Pale malt extract and 2# amber malt extract. Add to your brewing liquor and bring to 150 degrees. Add your specialty grains that have been lightly crushed. Add the crushed grains into a muslin sack consisting of 1# 45 Crystal malt,1/2# 120 caramel malt,1/4# chocolate malt,1/4# black malt,1/2# carafa malt,1.25#s wheat malt,1.5#s flaked barley, 1/2# roasted barley,1/2# special B and 1/2# aromatic. Steep the specialties in the 150 degree liquor for 45 mins. Remove the sack from your kettle and let the gains drip dry over the kettle as you bring the brewing liquor to a boil. Then add your Malt Extract (off the flame of course so not to scorch it), 18-20#'s of it should give you enough fermentables. Once you hit a boil add the hops as above and cool and ferment as above.

Good luck. Hope this helps Cheers! Tod Mott"

If you are not familiar with this beer, it is Portsmouth's most popular and currently brewed only once a year to fill 10 barrels - half goes on tap, half fills 900 bottles. It is definitely amongst the "celebrity" beers out there, and near impossible to get. Enjoy the recipe and hopefully we'll have a few successful clones to talk about later this year.

Cheers!