That was a typo - I meant LCD.

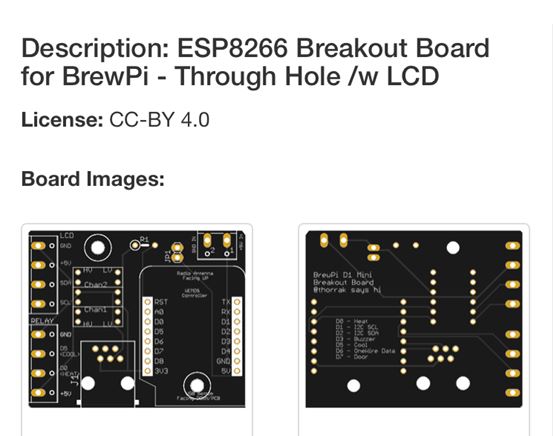

The idea is you use a PCB for the ESP-8266 coupled with a breakout board both listed on

this page. Then you can use a commercially purchased Ethernet cable to connect the two, and the breakout board would use either screw terminals or DuPont connectors depending on your preference.

The challenge there is that ESP-8266 board has a built-in level shift so you can't use it with your LCD. I've attached an updated ESP-8266 board design which uses an RJ-45 and no level shifter. (

@Thorrak please feel free to snag this and use it if you like, more and more the I2C LCD's are 5V.)

You just flash it with a new sketch (i.e. the Blink sketch or something). When you flash the regular firmware, you remove the old one.