Wow, that is just crazy!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My mostly automated brucontrol setup

- Thread starter Die_Beerery

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

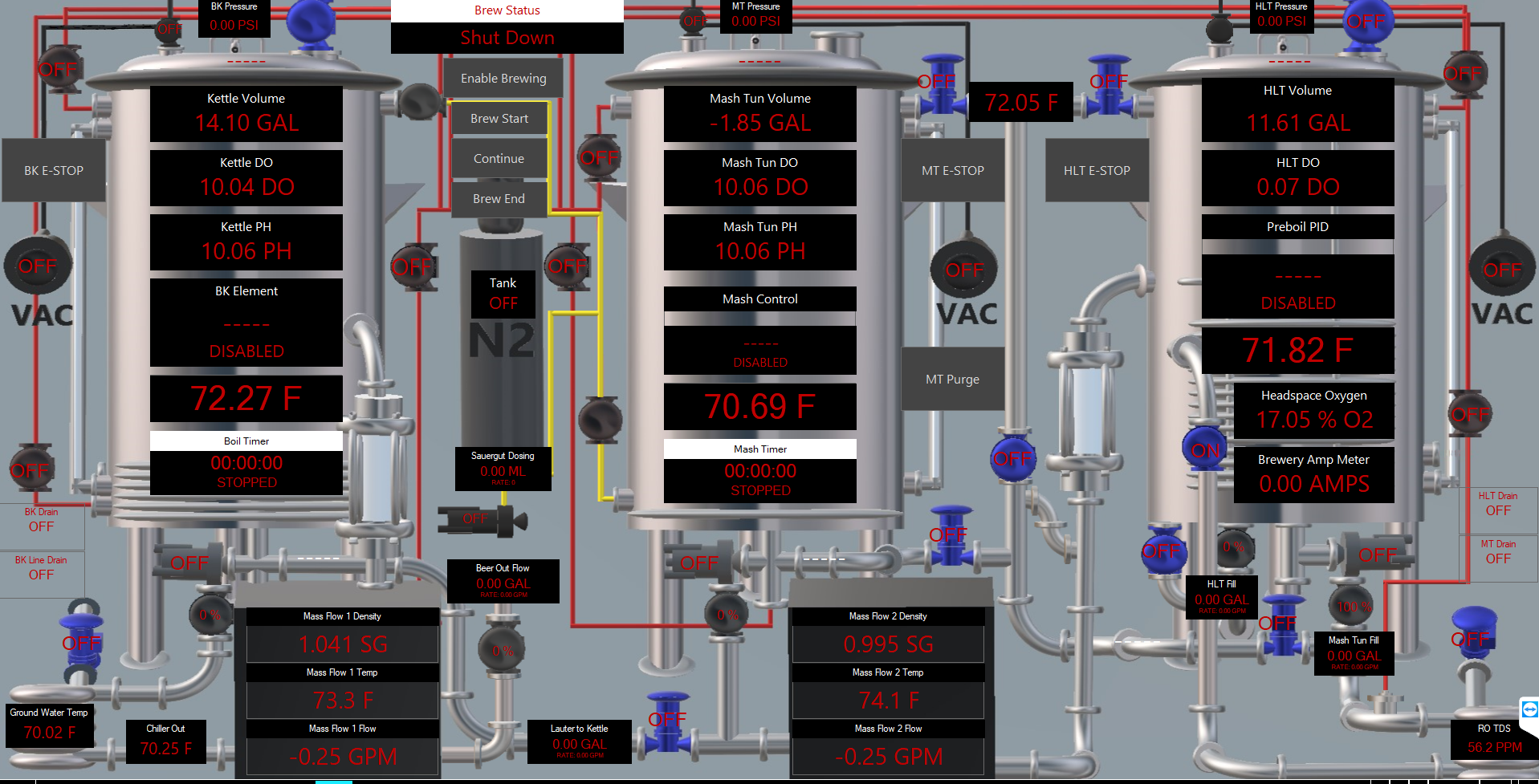

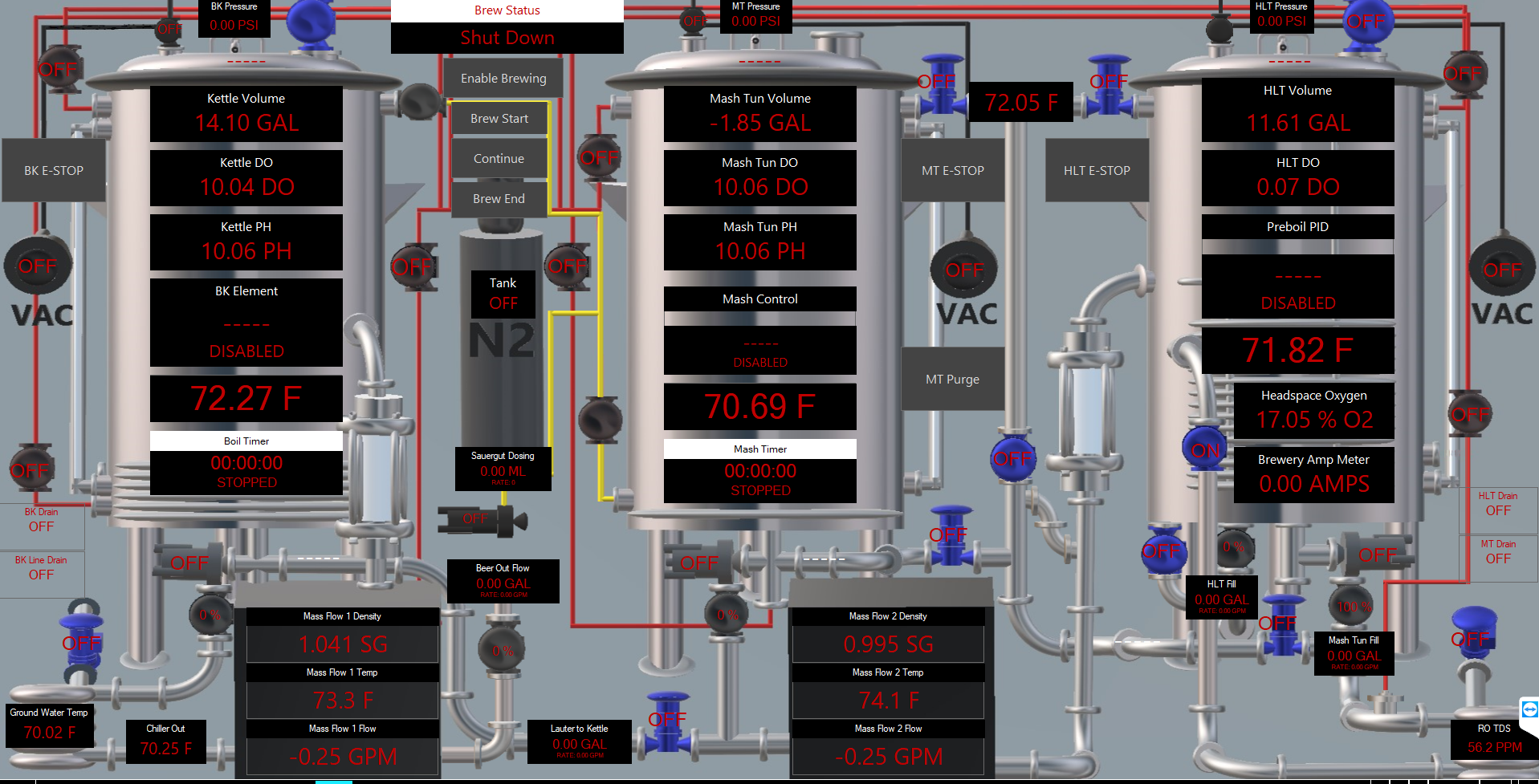

Control panel layout as of today..

All sensors check out.

I think the maiden auto brew voyage will commence Saturday

All sensors check out.

I think the maiden auto brew voyage will commence Saturday

- Joined

- Aug 7, 2014

- Messages

- 321

- Reaction score

- 182

You've done your homework. Should be a piece of cake.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

Getting really close! Started closing her up. T minus 36hrs till blastoff. We are either going to the moon or gonna blow up!

I'm fascinated with the background graphics of your control panel layout. If you don't mind me asking what program did you use to design your control panel layout (kettles,sight glass,valves,chillers etc..) with?

Best of luck with the initial launch!!!

Best of luck with the initial launch!!!

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

I'm fascinated with the background graphics of your control panel layout. If you don't mind me asking what program did you use to design your control panel layout (kettles,sight glass,valves,chillers etc..) with?

Best of luck with the initial launch!!!

Thanks

Microsoft paint 3d

Can’t wait to see if this thing makes sugar water! ;-)

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

Trying my hand at my 4th brew tomorrow.

Updates are here.

I still have to build cleaning, and acid dosing. Was playing with that a little tonight.

Updates are here.

I still have to build cleaning, and acid dosing. Was playing with that a little tonight.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

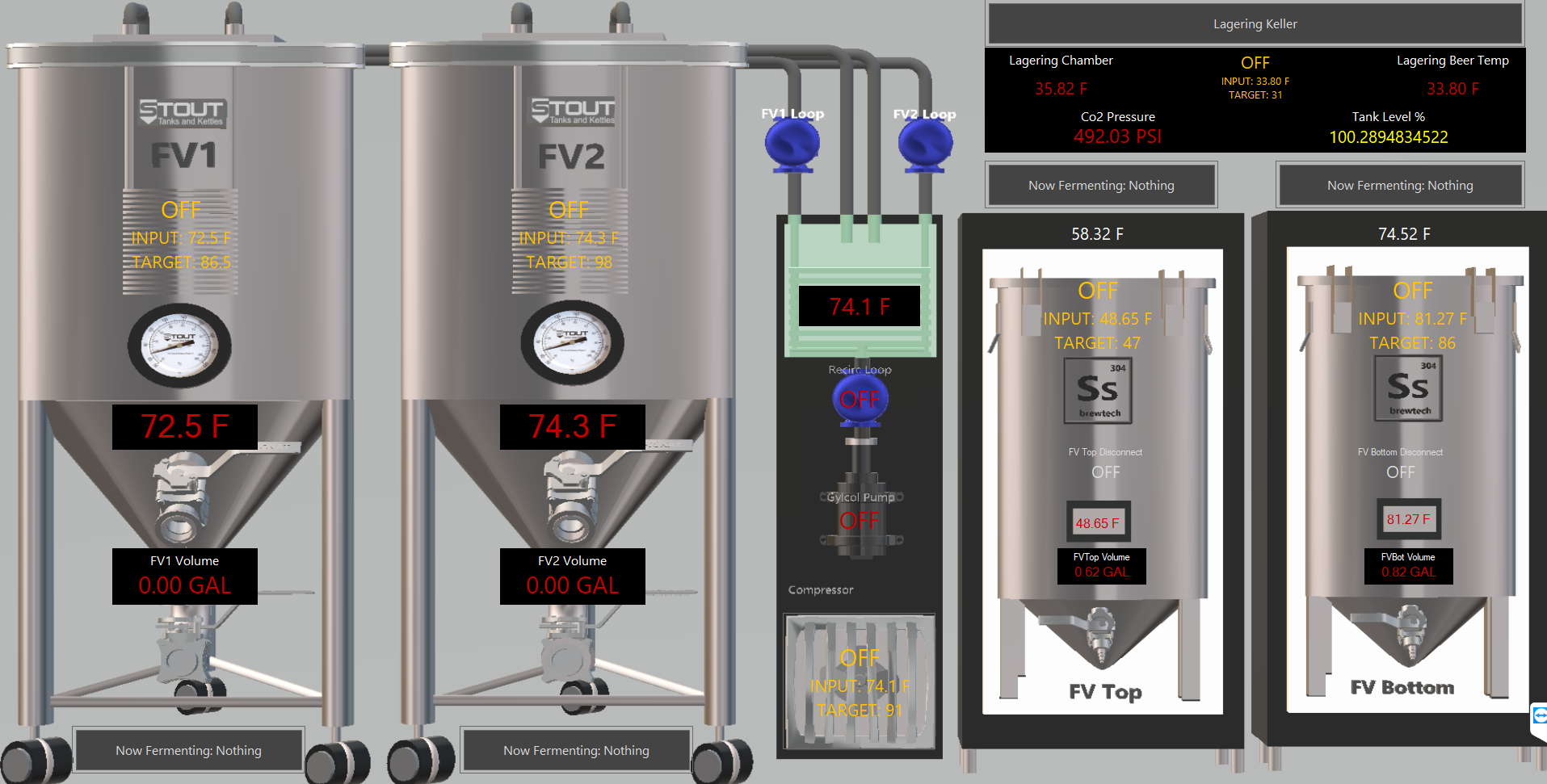

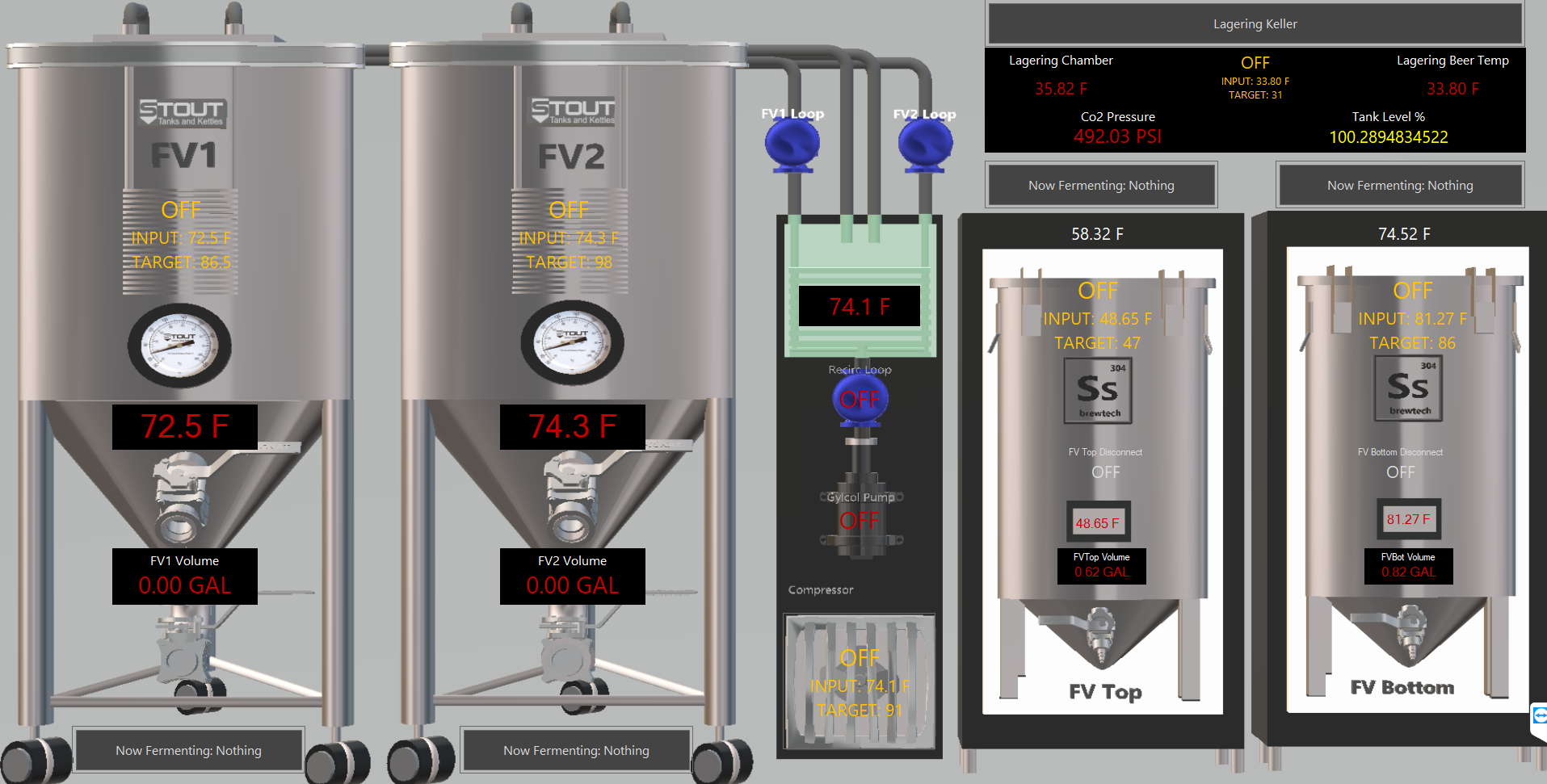

Brewed a few batches of beer this weekend found some issues and bugs nothing that can't be fixed. Re-tweaked the fermentation interface. Ordered the parts today for automating the fermenter transfer and auto spunding.

Pic is not coming up for me.

Edit: NVM, found it via web.

Edit: NVM, found it via web.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

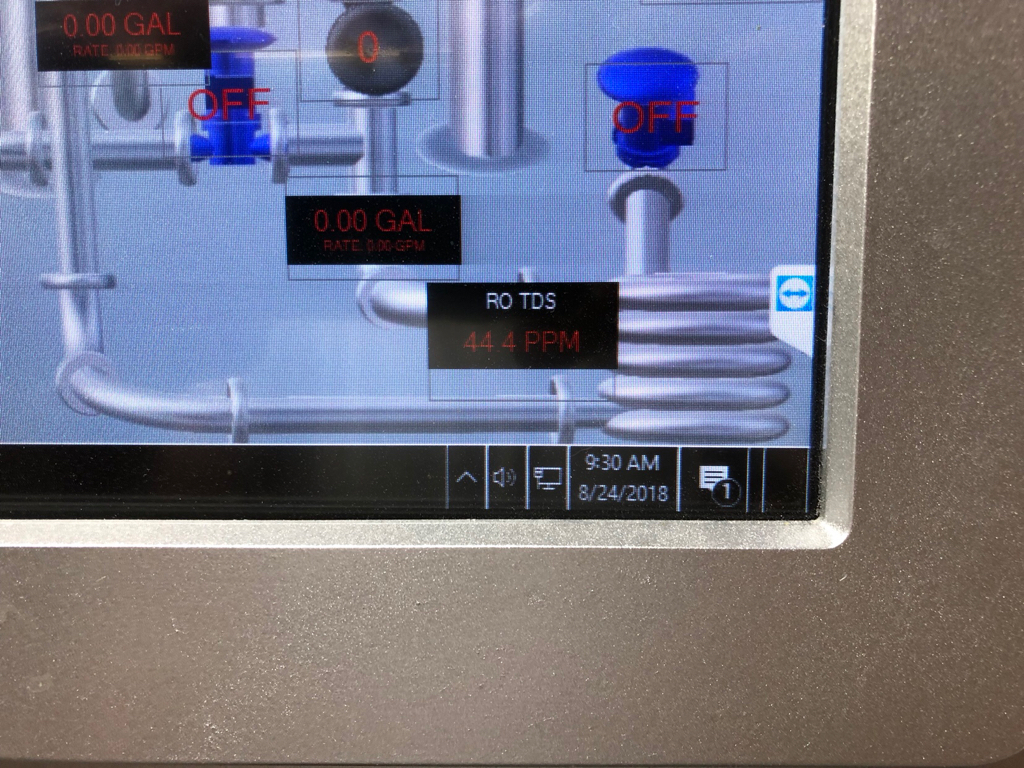

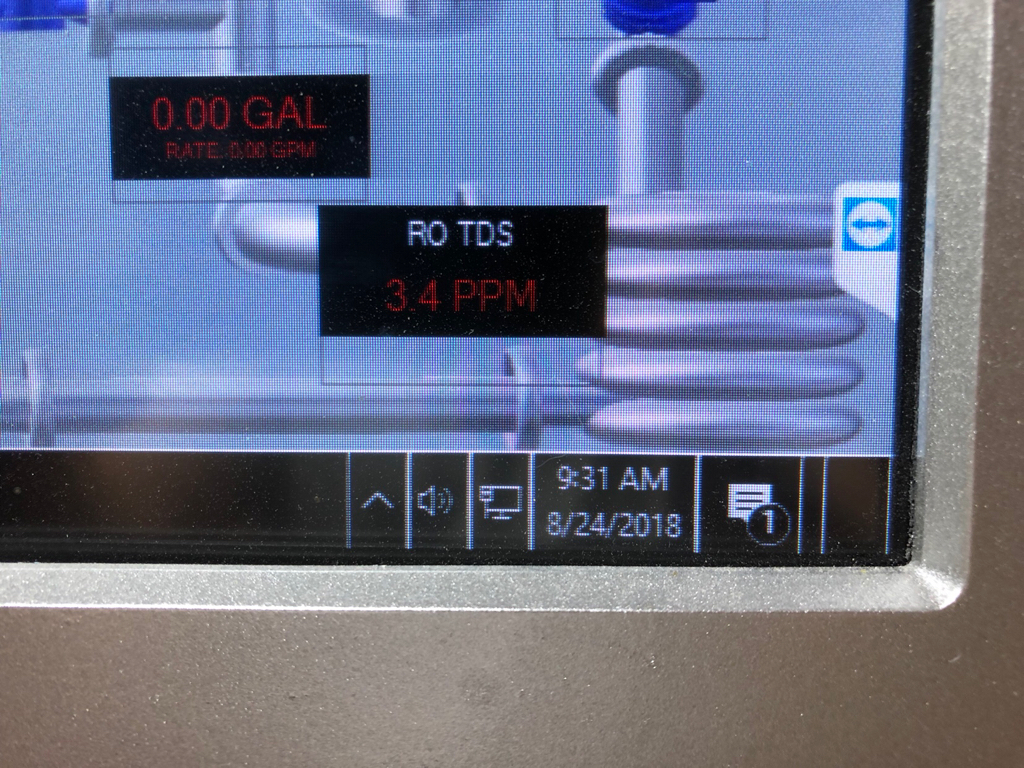

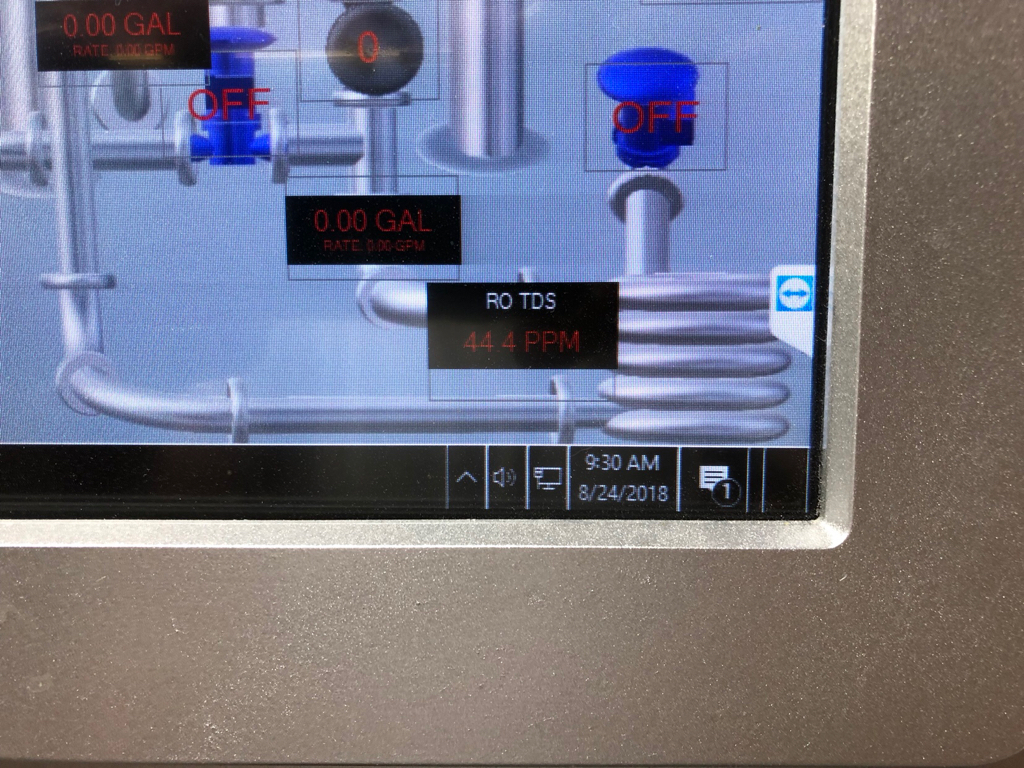

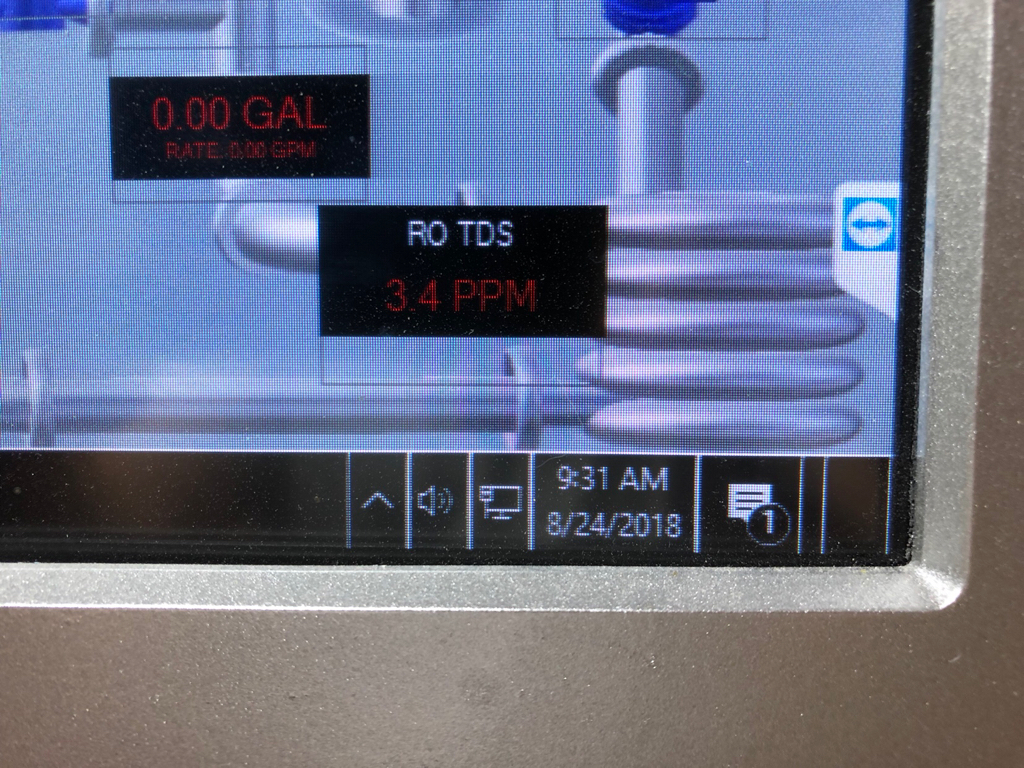

Added a digital TDS meter to the brewery. It will Monitor tds and email me when tds levels get to unacceptable ranges.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

Brewed a few batches of beer this weekend found some issues and bugs nothing that can't be fixed. Re-tweaked the fermentation interface. Ordered the parts today for automating the fermenter transfer and auto spunding.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

I have a bunch of batches though the systems and have all scripting issues figured out (all my fault). Brucontrol has exceeded my expectations, which is a really big deal.

I am working on putting it all together now, the whole brewing process from start to finish.

There are a few areas I need to explore. Namely malt storage, malt transportation, hoping, and fermenter to keg transfers.. I just finished with my "auto spunding" setup, so carbontation is set.

I am working on putting it all together now, the whole brewing process from start to finish.

There are a few areas I need to explore. Namely malt storage, malt transportation, hoping, and fermenter to keg transfers.. I just finished with my "auto spunding" setup, so carbontation is set.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

Update for those who care.

Still tweaking and adding stuff. Hardware wise only 3 things are left.. On the list is Hop additions, grain delivery, and grain storage. I plan on working on these things in that order.

Whats new?

Added pressure sensors to the brewing vessels to monitor pressure for purging and vac.

Added N2 tank solenoid

Added HLT Boil valve

Added BK Boil valve

Added Mash Bypass valve

Added Fermenter volume sensors (x4) (in anticipation for auto fermenter transfers)

Added more spunding setups (x4)

Added co2 tank monitoring with high pressure sensors, created a dynamic script showing % left (based on temp and pressure), and alarm notifications for leaks and low tanks (x3)

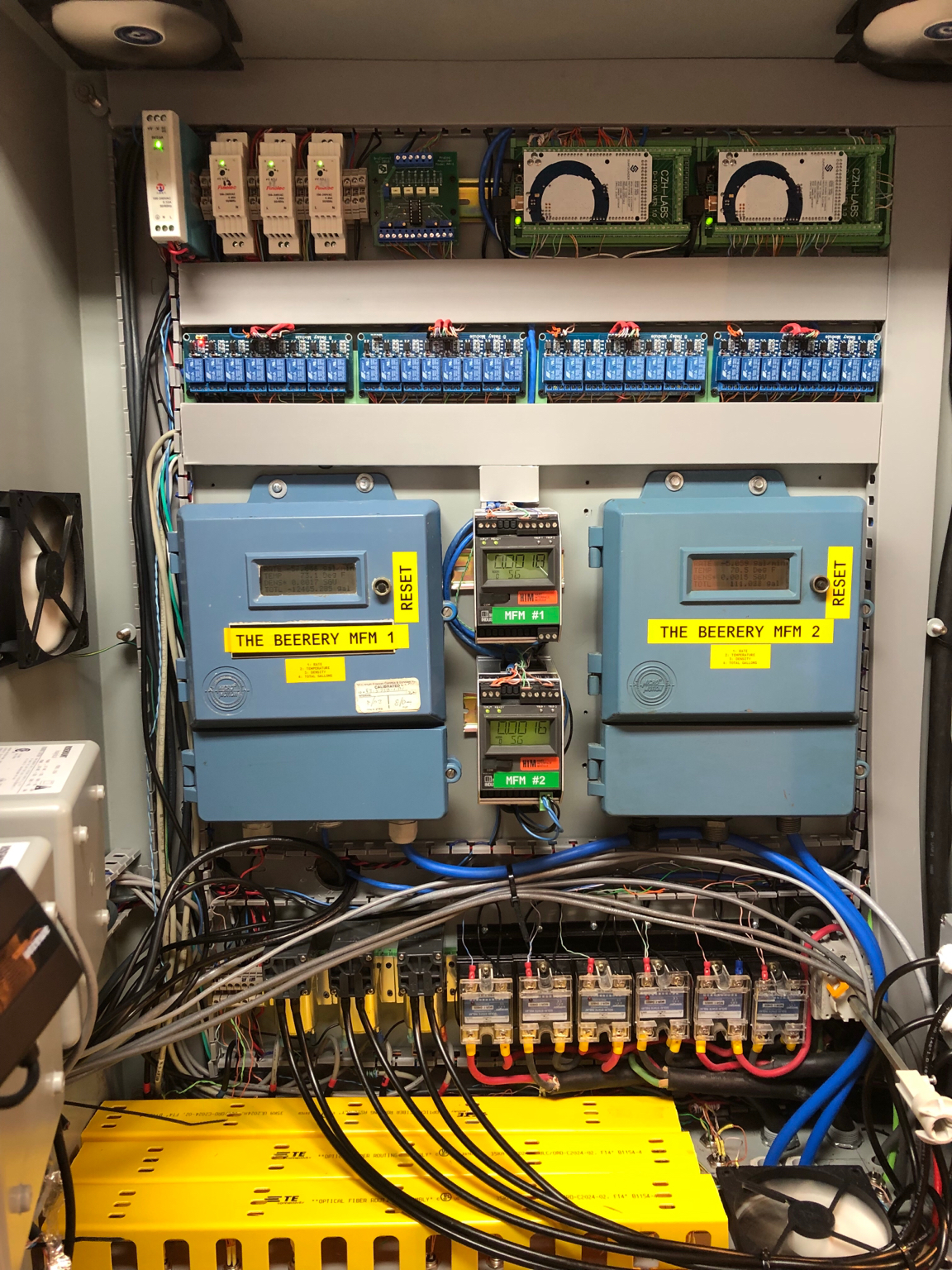

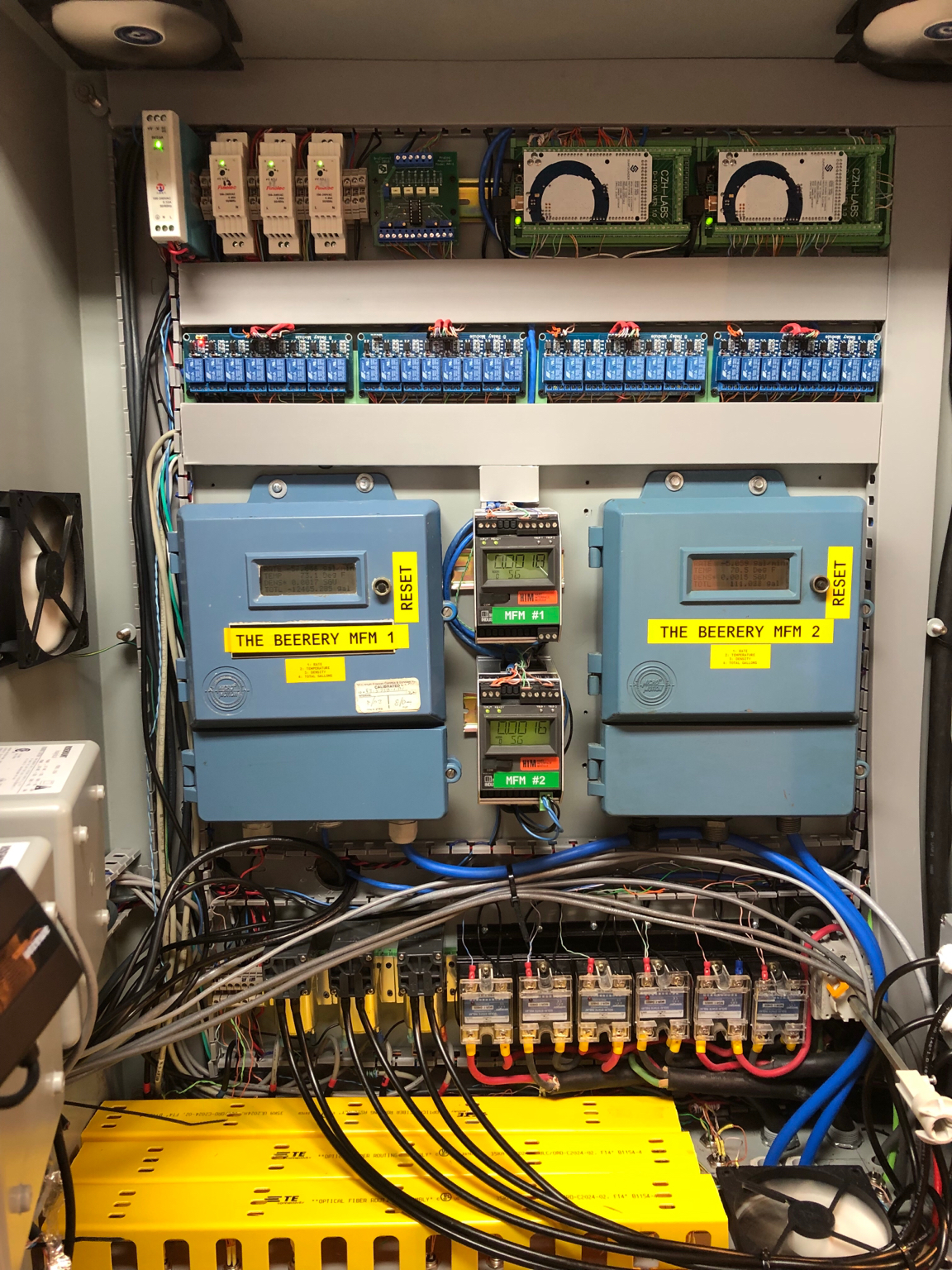

Closed up the Panel

Revised some scripts

Modified my brew buckets for larger valves (x2) (in anticipation for auto fermenter transfers)

I am sure there is more I am forgetting.

Panel Completed:

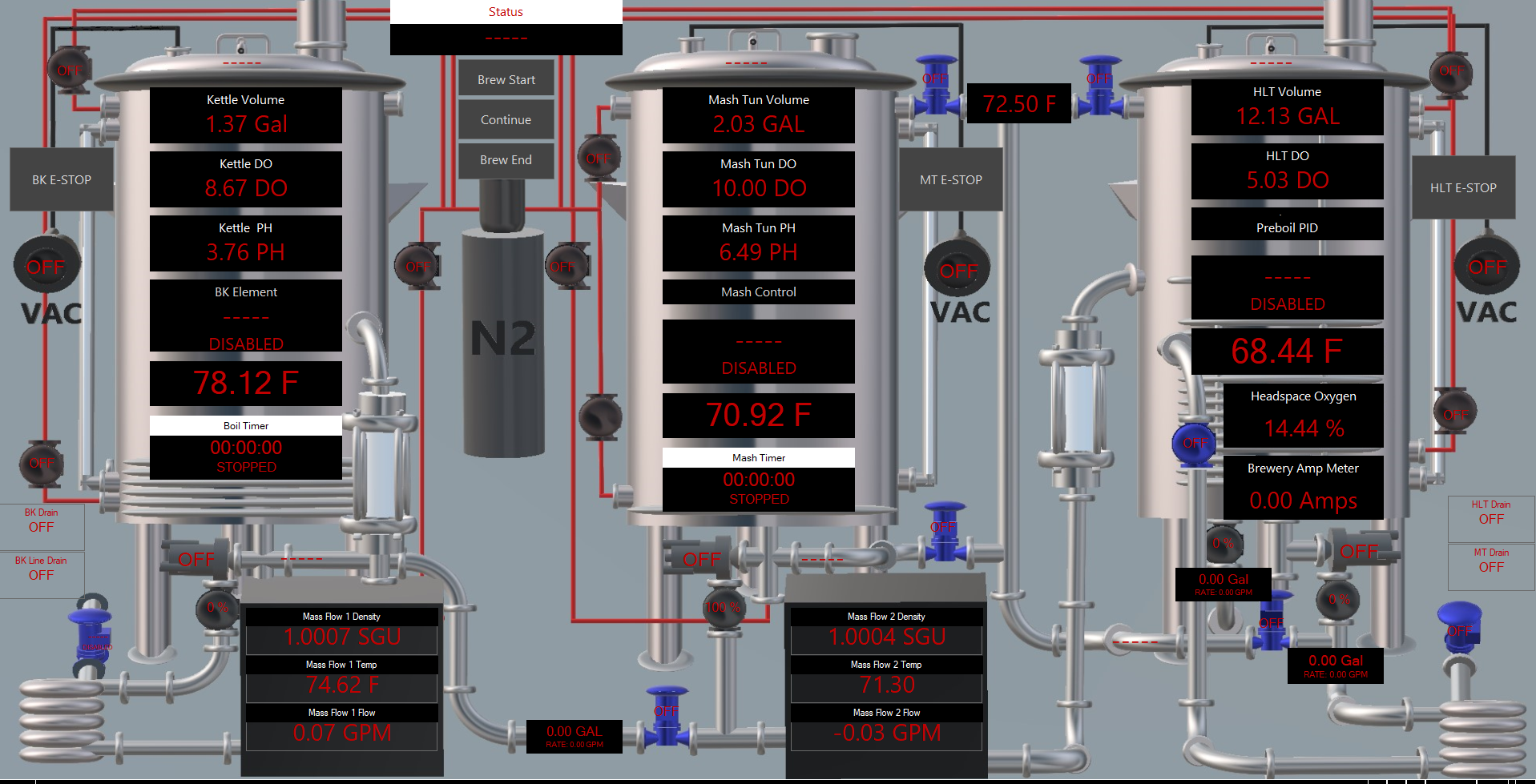

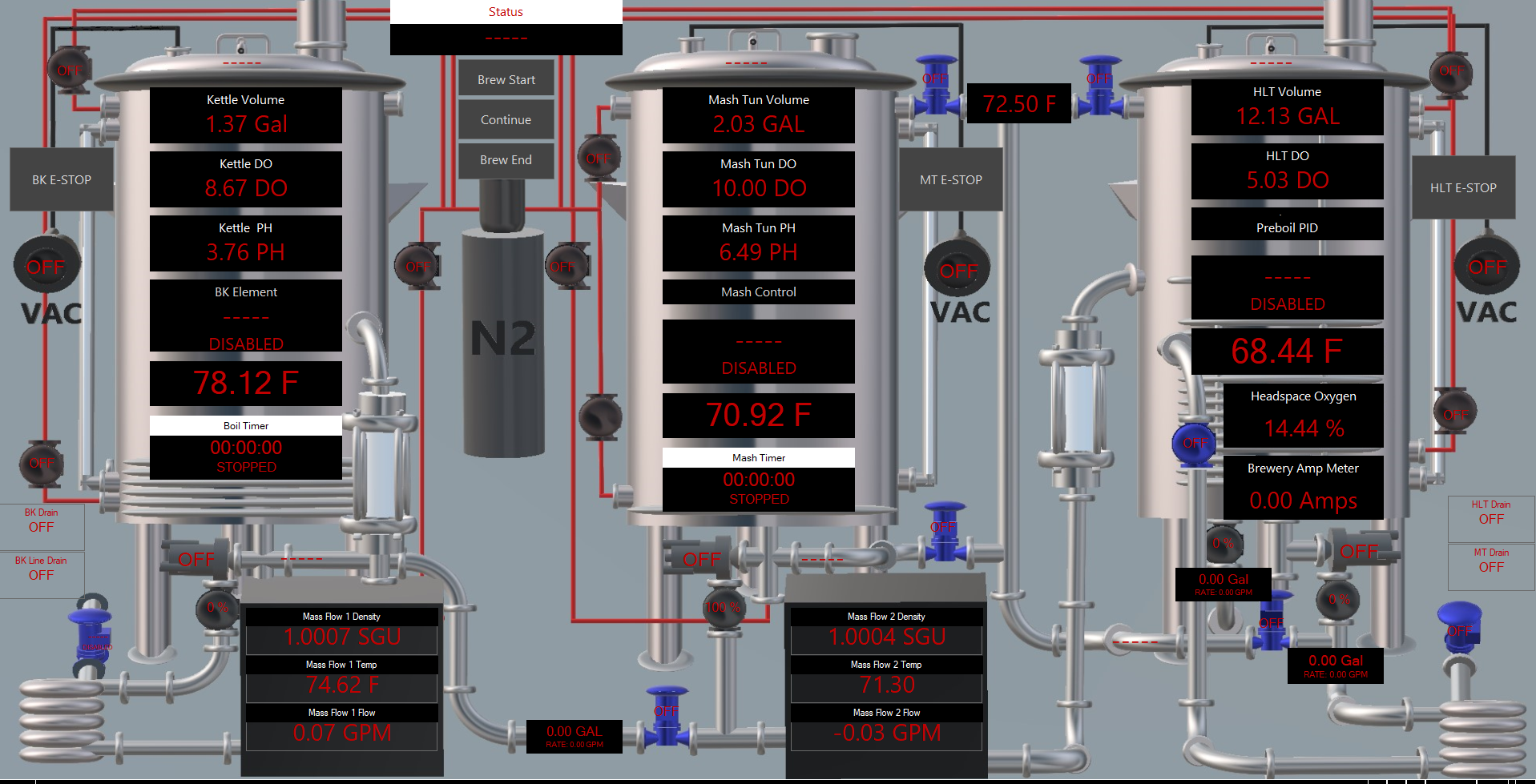

Revised Brewing Interface:

Revised Fermentation interface, Tank volumes in top right

Fermenter Modification

Some beers are finally starting to fill the pipeline. They are not quite ready, but close enough to start drinking.

Festbier:

72% Barke pils

20% Barke vienna

8% carahell

24ibu

Marzen:

80% Barke Munich

10% Barke Pils

5% carared

5% caraaroma

2oz sinamar (for color)

24ibu

Keller Pils

80% Barke Pils

20% light Munich

45ibu

Still tweaking and adding stuff. Hardware wise only 3 things are left.. On the list is Hop additions, grain delivery, and grain storage. I plan on working on these things in that order.

Whats new?

Added pressure sensors to the brewing vessels to monitor pressure for purging and vac.

Added N2 tank solenoid

Added HLT Boil valve

Added BK Boil valve

Added Mash Bypass valve

Added Fermenter volume sensors (x4) (in anticipation for auto fermenter transfers)

Added more spunding setups (x4)

Added co2 tank monitoring with high pressure sensors, created a dynamic script showing % left (based on temp and pressure), and alarm notifications for leaks and low tanks (x3)

Closed up the Panel

Revised some scripts

Modified my brew buckets for larger valves (x2) (in anticipation for auto fermenter transfers)

I am sure there is more I am forgetting.

Panel Completed:

Revised Brewing Interface:

Revised Fermentation interface, Tank volumes in top right

Fermenter Modification

Some beers are finally starting to fill the pipeline. They are not quite ready, but close enough to start drinking.

Festbier:

72% Barke pils

20% Barke vienna

8% carahell

24ibu

Marzen:

80% Barke Munich

10% Barke Pils

5% carared

5% caraaroma

2oz sinamar (for color)

24ibu

Keller Pils

80% Barke Pils

20% light Munich

45ibu

Really nice work!! The beer too!

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

What boggles my mind is how clean and simple your panel layout is, yet at the same time demonstrates the endless and complex possibilities BruControl has to offer. Well done Die_Beerery you have definitely taken this to the next level.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

What boggles my mind is how clean and simple your panel layout is, yet at the same time demonstrates the endless and complex possibilities BruControl has to offer. Well done Die_Beerery you have definitely taken this to the next level.

Thanks! If you can dream it, brucontrol can pretty much handle it. I am living proof there!

[...]Well done Die_Beerery you have definitely taken this to the next level.

"Next level"? He's about 100 levels above "next"!

Cheers!

So true. Honestly, I’m embarrassed that his build and implementation is so much better than I ever imagined possible!

Ahahahahahahaha!

It's like big time model railroading - the layout is never "done"...

Cheers!

It's like big time model railroading - the layout is never "done"...

Cheers!

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

How are you currently doing hop additions? if the system is purged and sealed, how are you adding hops at desired time-points?

It's not sealed during boiling.

Overkill

Well-Known Member

- Joined

- Oct 30, 2018

- Messages

- 57

- Reaction score

- 26

Ah that makes sense. So you open one of the ports and toss some in once your at 212 I assume. Cool. Do you re-purge the kettle with n2 during chilling?It's not sealed during boiling.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

Yes I do.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

Another question...are your HIM Hart loops each 2 analog out or 3 analog out?

3, I use them for density, temp and flow.

Overkill

Well-Known Member

- Joined

- Oct 30, 2018

- Messages

- 57

- Reaction score

- 26

Cool I bought the correct ones then. Wasn't sure if you could loop in-line with the HIM into the 24mA out of the 9712 and use 2ao (cheaper) from the HIM and 1 from the 9712 for the arduino, or if the 9712 needed a dedicated line to the HIM. This is simpler though. My 9712s, DS100s, HIMs, and smart 268 remote should be here next week. Might have some questions for you then. To start how did you clean the units when you received them. Just PBW?

Overkill

Well-Known Member

- Joined

- Oct 30, 2018

- Messages

- 57

- Reaction score

- 26

10" welded tri clamp fittings ordered from china for the 3 kettles (x3). drilling and welding several 1.5 inch tri-clover fittings into each.

Buch of crap still due to arrive like bunch of Broadley J DO sensors and Ph probes, Rosemount 1056 boxes, MT DO boxes, Hoffman Enclosure, relay boards, flow sensors, etc. Still need to get valves ordered from china also.

Hoping to get a good amount of welding done over thanksgiving on the kettles.

Attachments

Wow. Might want to document this in a unique thread. Looking forward to the welding!

View attachment 598031 MM Mass Flow DS100HView attachment 598032Better condition then expected one was a bit dirty but should clean up nice. View attachment 598034Bigger then I expected.

View attachment 598042

10" welded tri clamp fittings ordered from china for the 3 kettles (x3). drilling and welding several 1.5 inch tri-clover fittings into each.View attachment 598037pressure sensor spec'd from china. 0-3psi, 3x burst rating, 0.2% FS, 150C rated, X6. For Hydrostatic pressure volume determination of the pressurized vessels. View attachment 598038HIMS for the FRT 9712s arrived View attachment 5980393750 boil coil for the BK. View attachment 5980401 of 2 RTF 9712s due to arrive. View attachment 5980412 x 5500 W ripples for the HLT.

Buch of crap still due to arrive like bunch of Broadley J DO sensors and Ph probes, Rosemount 1056 boxes, MT DO boxes, Hoffman Enclosure, relay boards, flow sensors, etc. Still need to get valves ordered from china also.

Hoping to get a good amount of welding done over thanksgiving on the kettles.

Where did you get the pressure sensors?

Gameface

Well-Known Member

This.Wow. Might want to document this in a unique thread. Looking forward to the welding!

What the hell are you up to?

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 641

This.

What the hell are you up to?

Copying me! [emoji41]

Keep the pics coming!

John

John

Overkill

Well-Known Member

- Joined

- Oct 30, 2018

- Messages

- 57

- Reaction score

- 26

I ordered them to specification in china using alibaba. Specifically, Company: Shaanxi Qijia Automation Technology Co.,Ltd.Where did you get the pressure sensors?

The specs are:

Model: CAP-WS Pressure Sensor

Accuracy 0.2%

Pressure Type: Gauge (G)

Range:0-20kPa

Temperature Range:-40-150 degree

C

Output:4-20mA

Power:24V

Connection: tri-calmp 1.5 inch

(clamp mounting 50.4mm)

I sifted through a dozen supplies and took a lot of quotes before choosing them primarily on price and reputation.

I went with a little higher pressure rating (20kPa instead of 10) and higher burst rating (3x). At a 3psi max pressure, .2% FS accuracy i should get about 0.2 gallon of volume accuracy while still having enough room to pressurize the vessels to 2-3psi with N2. I bought 2 per vessel, and intend to subtract the head pressure from the vessel base pressure to calculate volume. In theory I should be able to do this https://www.viatran.com/static/medi..._notes/liquid_level_measurement_tech_note.pdf

In practice will find out soon enough how well it works compared to flow rate based calcs.

Similar threads

- Replies

- 5

- Views

- 435