Stealthcruiser

Well-Known Member

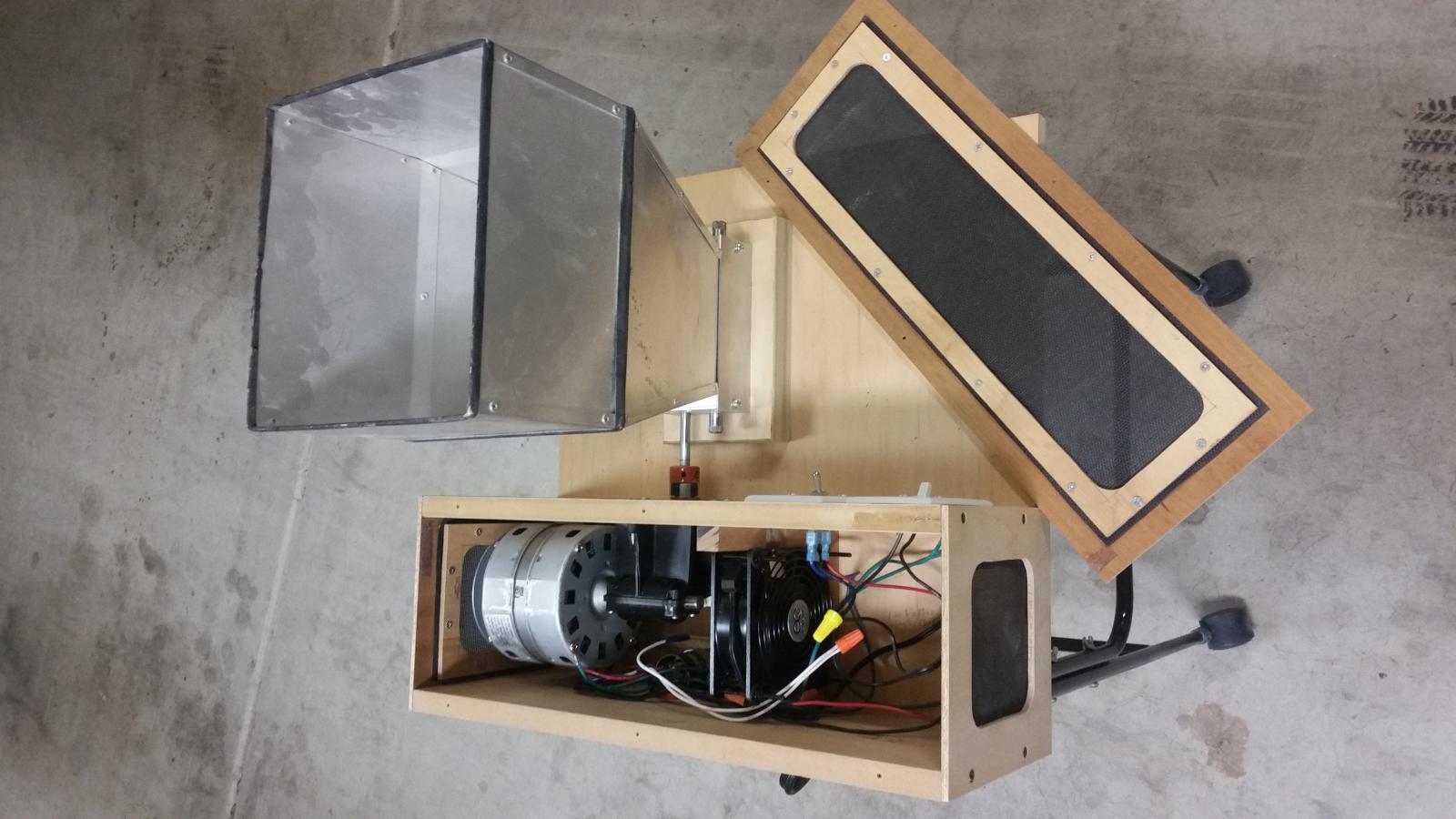

No ideas, without seeing the "business end".

Is that a "screw drive" opener?

If so, it may limit your options, as it only has to spin the screw, to lift the door.

What is the actual "drive"..........Belt driven?

Is that a "screw drive" opener?

If so, it may limit your options, as it only has to spin the screw, to lift the door.

What is the actual "drive"..........Belt driven?