Sorry it's been awhile since I've updated this thread but I've been working on an FAA certified flight instructor certificate and I haven't had much free time.

We're on batch #9 now at the Mineral Creek Brewery and the system has been working well and we're getting to know the ins and outs. After fighting with the 6 gallon carboys on big beers and wanting something better, we upgraded to two 15 gallon conical fermetors from Brewers Hardware. So far they've been great.

Here are a few photos of recent activity in the brewery...

2 Liter yeast starter on the stirplate...

Starter after 24 hours...

Grain for a Left Hand Brewery Fade-to-Black Vol I clone...

Fade-to-Black fermentation. Need more headspace!

The Fade-to-Black turned out great at 8.6% ABV...

Grain and hop bill for a Bell's Two Hearted clone from

www.theelectricbrewery.com

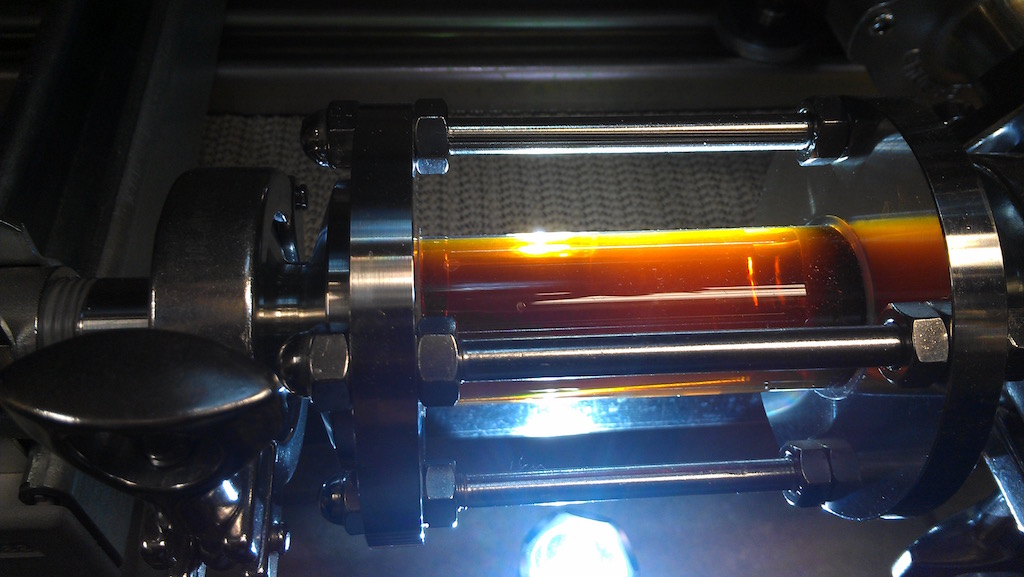

Raging Red wort color during the mash. Recipe from forum member @Mysticmead

https://www.homebrewtalk.com/showthread.php?t=239188

Raging Red hydrometer sample at 1.061...

Raging Red finished beer...

Heat/Cool controller for fermentor temperature jacket under construction...

A nice simple hopped up Blonde Ale...

Thanks again to everyone for the nice comments. This has been a really fun project!