1MadScientist

Well-Known Member

Table sugar is used to check hydrometers.

I've ordered a 0-12 brix hydrometer, should have it next week to do some more testing. It has 0.1 brix graduations, which should give me a pretty accurate picture.

I'm perfectly happy with the standard models of hydrometer and refractometer. Two significant digits is plenty accurate enough, whether you're talking about ABV (5.03% vs. 5.04%, who cares!), specific gravity (1.0513 vs. 1.0514, I don't care!), etc. The average homebrewer thinking that they can measure anything good to 3 sig figs in a non-laboratory setting is very likely just fooling himself/herself, as there's probably dozens of variables and margins for error all going on at one time and it's hard to come up with all of them. Even a slight draft of air, or humidity, or a few degrees temperature difference between instrument and the thing being measured can sometimes mess things up. Alcohol also (if present) quickly evaporates and I know for a fact can royally mess up any final gravity readings with a refractometer.

But anyway...

1.05 is three sig figs, and most homebrewers want better resolution than that.

The 1. is not significant, but only the digits after the decimal.

Cheers.

Not a weekend project.

Received my 0 -12 brix hydrometer today. In 20C distilled water, it reads 0.5 brix. For some reason I was expecting better as it comes with NIST and ASTM certification. Oh well, with some adjustment it should let me check my refractometer.

What is the calibration temp printed on the paper insert?

Brew on

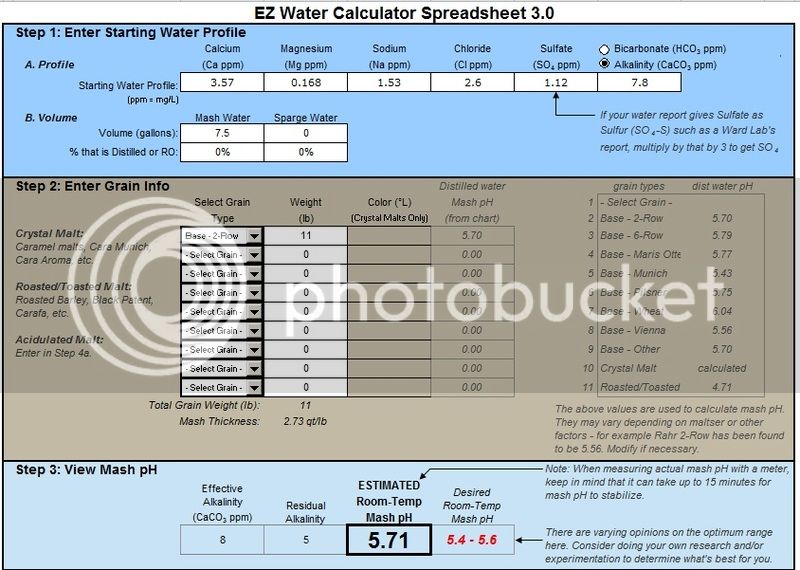

Mash pH may have been VERY high because it was a SMASH beer. Specialty grains bring pH way down. Without any then I would not be surprised if pH was 6.0, way higher than the recommended 5.3-5.5.

Yeah, you're pretty much forced to add acid to SMASH beers to get pH into range.

Mill gap wasn't tight enough either.

Yeah, you're pretty much forced to add acid to SMASH beers to get pH into range.

I am going to triple check my grain mill crush next and reduce the grind from 0.039" to 0.035"??

I set my mill to .035" (thickness of a credit card) then double crush the grains. Works great for me.

i set my mill to .035" (thickness of a credit card) then double crush the grains. Works great for me.

Do you guys recirculate?

If yes, I will try your method of 0.035" and double crush

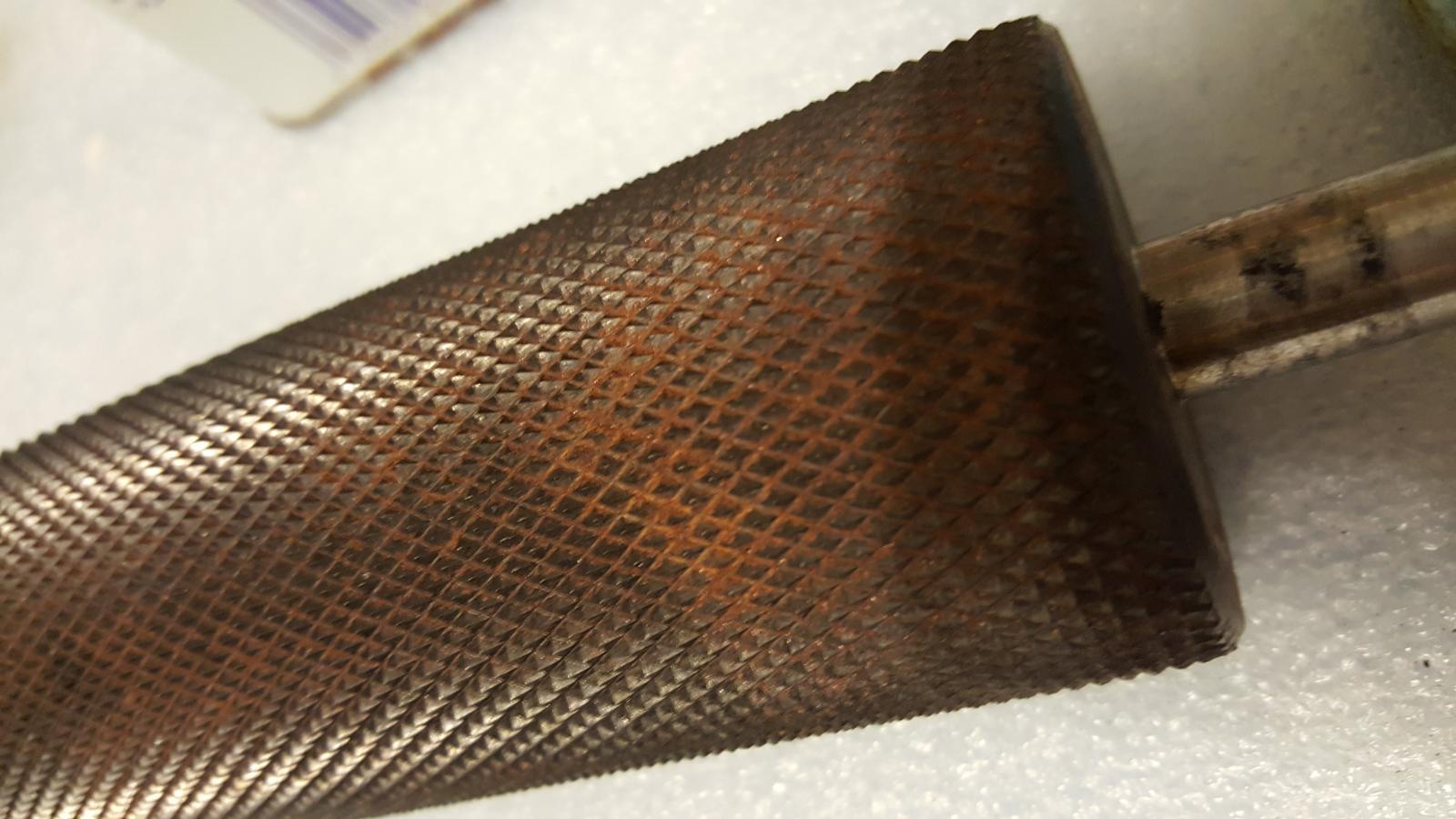

Got my new knurled rollers! They arrived pretty rusty. I spent an hour and some elbow grease polishing up the axles, and I think I'll try to find a wire brush to clean up the knurling somewhat before putting them into service. I'm excited to see what kind of efficiency gains I get.

Why is it rusty?

Why is it rusty?

I think you need to tighten your mill, quite a bit.

.

I was able to brew for the first time using the new knurled rollers on my mill yesterday. One observation is that the knurled rollers are slightly wider in diameter than the helical rollers, though both are specified as 2". The practical implication is that while I couldn't set the mill gap with the helical rollers below 0.022", I can now set the mill gap all the way down to 0. I found that most people are setting their mills with knurled rollers at a gap around 0.035" so I set my mill to 0.030" as I don't have to deal with stuck sparges doing BIAB. The knurled rollers set to a 0.030" gap produced a crush that was noticeably finer than what I was seeing with the helical rollers set to a gap of 0.022".

It was cold yesterday, and though I wrapped the kettle in a sleeping bag, I found the mash was losing about 1.5 degrees F per 15 minutes, so I turned the burner back on at 15, 30, and 45 minutes to bring the mash temperature back to my target 152F. The result is that the mash temperature fluctuated from 150.2F to 152F for 60 minutes. An added benefit was that the mash received a couple of minutes worth of stirring every 15 minutes.

I checked the volume markings on my kettle earlier this week and found that they are off by ~0.3 gallons. I accounted for this and am now confident my measured volumes are accurate to < 0.1 gallon.

I chose to brew the Mosaic Honey Wheat recipe for the third time, to see if I could produce any efficiency gains over my previous attempts with the helical cutters.

9 pound total grain bill (4.082kg)

4 pounds Great Western organic 2 row

4 pounds Great Western organic white wheat

1 pound Gambrinus honey malt

Mashed in 7.37 gallons of RO water with the following additions:

4.5g gypsum

4g calcium chloride (4.3g measured to account for hygroscopic nature)

2g baking soda

4mL 88% lactic acid

I heated my strike water to 157.3F, mashed in, started my timer, then stirred for a couple of minutes before closing and insulating the kettle. Where possible, I tried to take measurements with both my Milwaukee MA871 refractometer and a 9-21 brix precision hydrometer. All samples were covered and chilled to 20C prior to measurement.

15 minutes into mash:

temp - 150.5F

pH - 5.21

refractometer - 4.1

30 minutes into mash:

temp - 150.4F

pH - 5.29

refractometer - 6.0

45 minutes into mash:

temp - 150.2F

pH - 5.38

refractometer - 8.3

60 minutes (mash end):

temp - 150.7F

pH - 5.39

refractometer - 9.1

hydrometer - 9.3

After removing and squeezing the bag:

volume - 6.6 gallons

refractometer - 9.5

hydrometer - 9.8

With the new knurled rollers, I was hoping to see a better crush, improved conversion efficiency, and faster conversion (was hoping conversion would be mostly complete by 30 minutes). I did see the improved crush, and slightly improved conversion efficiency. I did not see the conversion process complete by 30 minutes, and to my disappointment the SG was higher after squeezing the bag than it was at the 60 minute mark, likely meaning that conversion had not completed.

Putting the formulas here to use, I came up with the following conversion efficiencies:

60 minutes:

refractometer - 85%

hydrometer - 87.6%

post-squeeze:

refractometer - 89.7%

hydrometer - 92.8%

So if you believe the hydrometer is most accurate, I came close to seeing good conversion after squeezing the bag. As has been discussed previously in the thread however, measured brix/sg should be the same at the end of the mash as it is after squeezing the bag. The fact that it wasn't means conversion was not complete. The mash was stirred thoroughly throughout the 60 minutes, so I can't imagine that is the issue.

I think next time I'll try dropping the mill gap to 0.025" and see what happens, but I'm no longer holding out hope. Something about my system just doesn't like producing good conversion efficiency, and after 4-5 months, 9 batches of beer, a lot of time, effort, and money, I still can't figure out what it is.

Your conversion was likely done at 30 minutes but when conversion happens the wort is more dense than water and sinks, leaving you with less dense water near the surface. During the rest of the time the sugary wort will disperse into the less dense water making you think that you are still getting conversion. Next batch, stir very well before taking your refractometer sample. I'll bet that your reading will not change from the 30 to 60 minutes if you get the wort mixed well.

On my last batch I took a refractometer sample about 3 minutes into the mash, then another one at 15 minutes and found that the gravity had gone down. I know that with some religions you can unconvert but I doubt that I had unconversion in my mash.

Enter your email address to join: