There isn't really a reason you'd have to wait for a new batch to test your conversion efficiency. 2# of 2-row and a gallon of hot water are cheap, you can just dump it when you're done.

For what it's worth, I keep my Cereal Killer between the 0.025 and 0.050 marks on the side and get fairly good conversion efficiency, but I also found early on that I was putting volume numbers into Brewer's Friend "wrong" based on my BIAB approach.

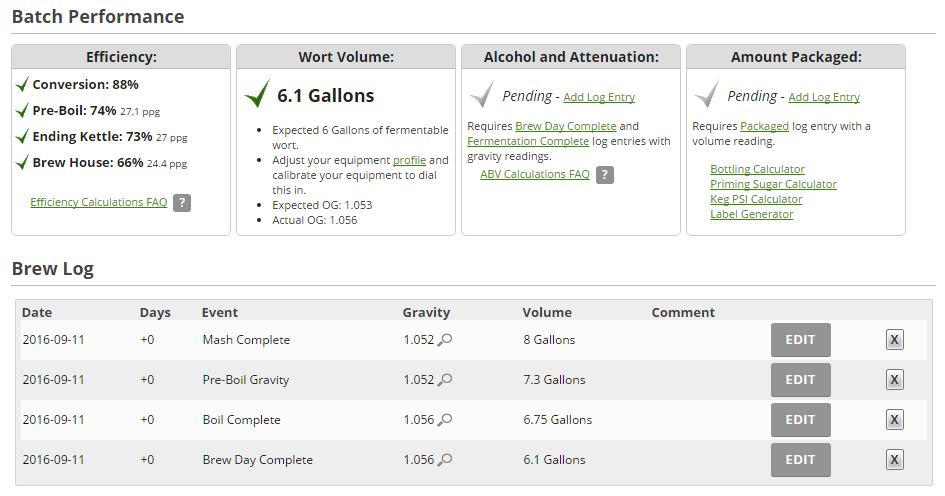

"Mash Complete" Step - Enter the total strike water volume

"Pre-Boil Gravity" Step - Enter the volume after you've squeezed the grain bag

"Boil Complete" Step - Volume in the kettle after you chill it but before transferring

"Brew Day Complete" Step - Volume in the carboy

Using this approach means that each step can only have one source of "loss".

Mash - Conversion Efficiency

Pre-Boil - Lautering Losses

Boil Complete - N/A

Brew Day Complete - Transfer and Trub Losses (and any losses because it wouldn't fit in the carboy)

http://cdn.brewersfriend.com/understanding_efficiency_large.png

I included a snapshot of the brew I did Sunday morning. It was a 20 minute mash / 20 minute boil which meant my conversion efficiency wasn't great (88%), and I overshot my final volume which ended up being the biggest hit on my brew-house (BH 66%).

For my process the biggest things that have helped improve my conversion efficiency were:

1. Mind the Gap - I am more consistent with my home mill, and I keep it relatively tight.

2. Stir the Mash - Unless it's a short mash I stir every 15 minutes during the mash. It has helped out considerably.

I honestly worry less about brew-house efficiency numbers because they swing so much depending on how much trub and hops you send into the carboy. Brewer's Friend lets you pick the ending kettle volume instead of the carboy volume as your batch size target which normalizes your efficiency a bit.