Hello all,

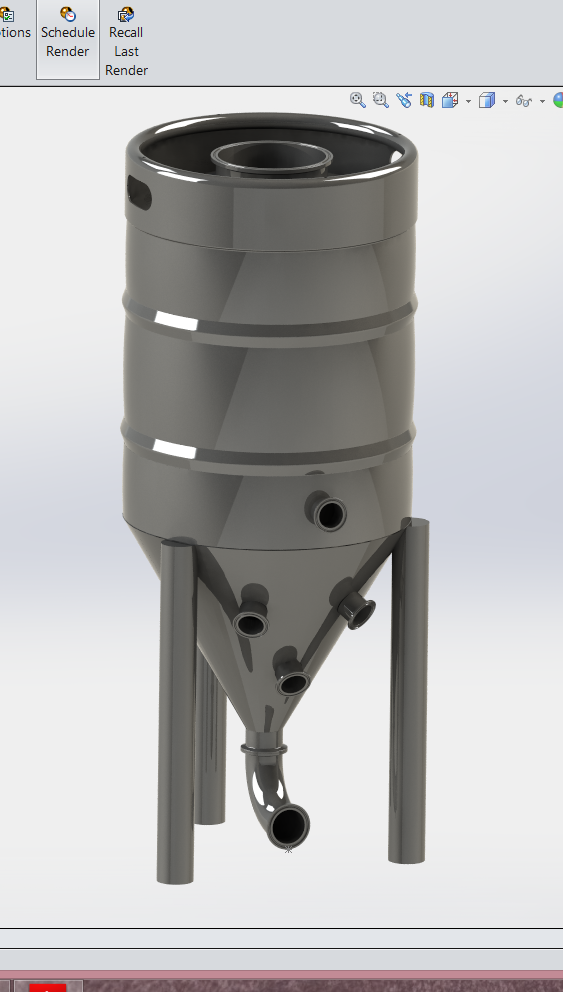

My brother in law is a welder working for an engineering company that makes, repairs and installs various kinds of tanks (and things) including large Unitanks. As someone who wants a pressure fermenter but doesn't really want to pay for one, I requested he build me a 50litre Unitank in exchange for beer. He said he would try find time for it at some point (hopefully soon) but had some questions about specifications and required functionality. Has anyone built a unitank or done specifications to have one made. I've never even used a pressure fermenter so any help would be appreciated.

Information on DIY homebrew unitanks is impossible to find!

My brother in law is a welder working for an engineering company that makes, repairs and installs various kinds of tanks (and things) including large Unitanks. As someone who wants a pressure fermenter but doesn't really want to pay for one, I requested he build me a 50litre Unitank in exchange for beer. He said he would try find time for it at some point (hopefully soon) but had some questions about specifications and required functionality. Has anyone built a unitank or done specifications to have one made. I've never even used a pressure fermenter so any help would be appreciated.

Information on DIY homebrew unitanks is impossible to find!