Try a commercial bottle conditioned beer.

No. A commercial beer served on his keg serving system.

Try a commercial bottle conditioned beer.

Then you throw out the thing about sour beers. It's true that sour beers take a long time to age, but is that because it takes time for the flavors to meld, mature and become pleasant to our palettes, or because it takes time for the sour flavor to appear in the beer? I honestly don't know; I've never tasted a young sour. But I would put money on the fact that within 2-3 days of pitching a vial of Brett, Lacto, or anything else into beer that you are going to taste it.

Again - I'm sorry that you are offended, but you appear to be offended because I won't take your word for it.

I've been absent from this thread for a while but it seems nothing has changed...

please, please, please - BOTTLE A BATCH!!

I'm sorry, but your assumptions are just wrong. If you pitch Brett or Lacto, it WILL take time to taste it. It does not start contributing flavors immediately. And YES, this is why sours take time to age and for the flavor to develop. You asked for advice and I'm telling you a few things I know. I don't brew sours, but am part of a brew club with 200+ members. Many do brew sours. They would 100% agree that wild yeast and intentionally added yeast, like Brett, will take time to impart flavor. I have no intention of scouring the internet for evidence to prove this to you.

Either believe or don't.... or better yet do some research yourself since you already stated you wont believe what anyone on here says... even though you are looking for advice?!?! Do you see the issue here?

What could possibly happen to beer in 2-3 days that would make it go from good to undrinkable?

Can you explain why beers fermented in buckets that have had prior infected batches in them taste bad right out of the bucket but batches fermented in new buckets taste fine?

even when your claims directly contradict physical evidence.

You admit knowing nothing about sours.

This is absolutely not true. Are you a microbiologist or do you have a professional background in that field?

I do not, but I do know a little about it and this statement is simply not true.

I'm seriously imploring you to do a little of your own research and look into it yourself. You have an idea in your head that has absolutely no physical evidence to prove, but yet you refuse to believe me because I'm not producing physical evidence.

Brewer's yeast takes days to impart flavor in beer, but literally every other micro-organism known to man takes weeks if not months to do the same thing. Do you see why this is hard to believe?

That's a terrible analogy. Brewers yeast takes only a few days to impart flavor when several hundred billion cells are added to 5 gal of wort. Reduce the pitching rate to that of a few hundred or even thousand cells hiding in the scratches in the plastic, and it takes much much longer for the cells to multiply enough to impart any noticeable flavor to the beer. Pitch a yeast vial full of bacteria in your beer, and you might be able to taste it instantly.

So I am fairly certain that the Glacier brand reverse osmosis water is indeed filtered using reverse osmosis but then they add their own make up of minerals for taste since they sell it as drinking water. Perhaps when you add extra minerals to their water there is an excess of minerals which may give an odd flavor when carbonated. I am certainly no expert and just getting into home brewing but I know that most filtered water companies add minerals to their water for taste. Maybe you could try bottled spring water with no additives.

It's a very real possibility it's a water issue compounded by the co2 in his system.

OP, you have no idea what you're talking about.

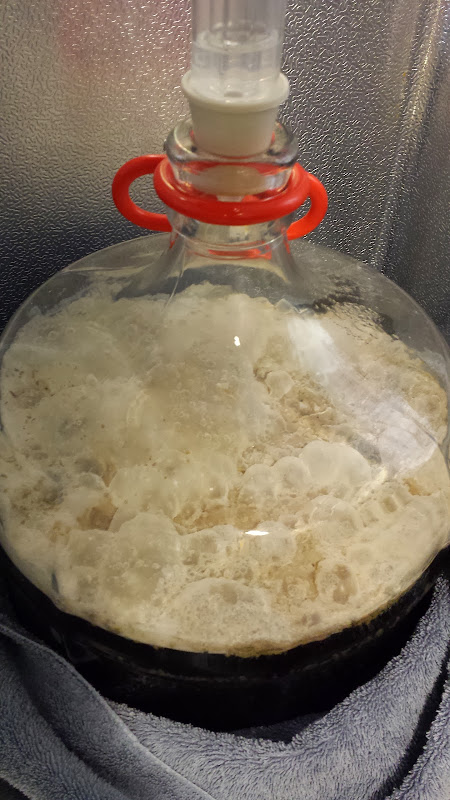

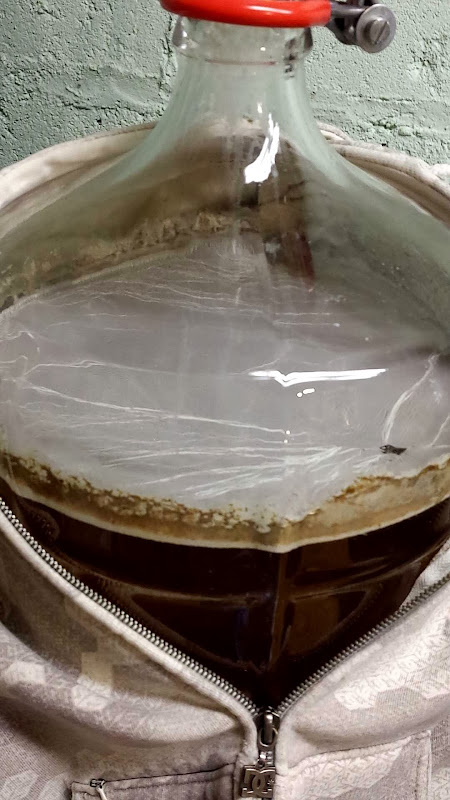

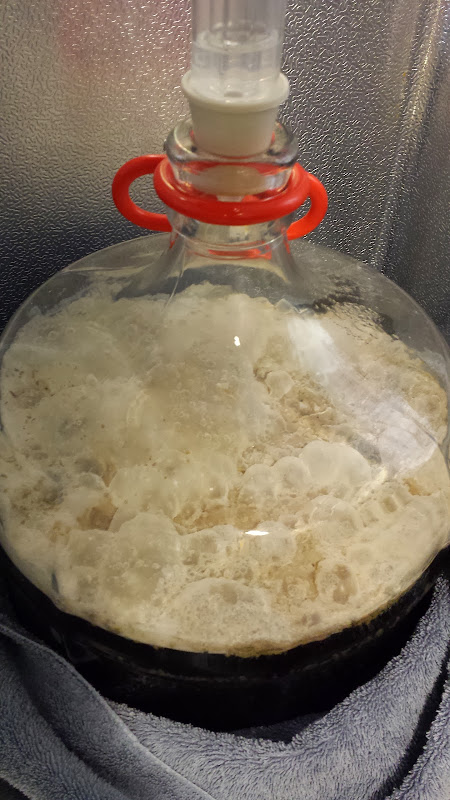

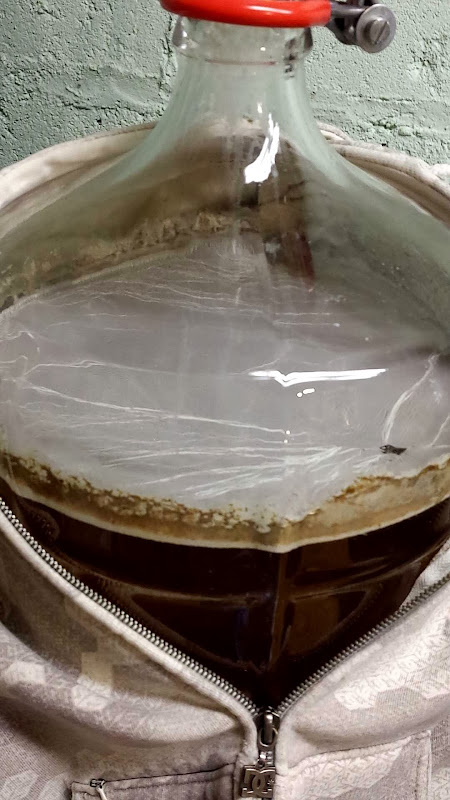

If he wants physical evidence, here you go. I don't think it will get any more "physical" than this...

Berliner Weisse fermented with 100% WLP677 at ~90* for 7 days. Absolutely no sour/lacto taste after 7 days, backed up by my ph meter, or "physical evidence" as you so eloquently put it.

After 4 months, the sourness starts to come out and the pellicle forms.

Motherf*****, why am I still wasting my time with this d-bag thread.

That's a terrible analogy. Brewers yeast takes only a few days to impart flavor when several hundred billion cells are added to 5 gal of wort. Reduce the pitching rate to that of a few hundred or even thousand cells hiding in the scratches in the plastic, and it takes much much longer for the cells to multiply enough to impart any noticeable flavor to the beer. Pitch a yeast vial full of bacteria in your beer, and you might be able to taste it instantly.

There are a few types of bacteria that create compounds with low enough taste thresholds that a flavor is imparted relatively quickly, but unless you're leaving large chunks of infected materials in your transfer equipment, it's highly unlikely that you'd taste anything after only a couple days from the time of infection.

This sounds like a very reasonable possibility and a GREAT suggestion. The OP has denied it's a water profile issue about 100 times in this thread, and from what I've read, refuses to try spring water with no additions, refuses to try an extract batch, and refuses to bottle some of the batch. It's a very real possibility it's a water issue compounded by the co2 in his system. He's convinced it's an infection and completely blind to any other possibilities or advice.

OP, you have no idea what you're talking about.

So I am fairly certain that the Glacier brand reverse osmosis water is indeed filtered using reverse osmosis but then they add their own make up of minerals for taste since they sell it as drinking water. Perhaps when you add extra minerals to their water there is an excess of minerals which may give an odd flavor when carbonated. I am certainly no expert and just getting into home brewing but I know that most filtered water companies add minerals to their water for taste. Maybe you could try bottled spring water with no additives.

This is exactly what I went through last year. There was a weird flavor that I couldn't describe. It was undetectable out of the carboy but as soon as it carbed up, the flavor would creep back in. It seemed reasonable at first to think it was some sort of weird infection but troubleshooting that route didn't work. As soon as I changed my water source, the problem was fixed.

I explained my issue in more detail in another thread. The member who started the other thread is also in Cali (Same as OP), and has been experiencing issues since October (Same as OP).

https://www.homebrewtalk.com/f39/5-years-into-great-hobby-i-feel-like-giving-up-460902/

LovesIPA, this is my conclusion, for what it is worth:

It is not a sanitation of infection issue. Your are convinced it is, so you have banged your head against the wall and ruined countless batches of beer trying to troubleshoot a problem that doesn't exist because you convinced yourself of the problem early on and never looked back.

This is a water issue. Plain and simple. I noticed you're from California. Let me direct you to this article:

WATER VENDING MACHINES TARGETED BY LAWSUIT

In summary, Glacier RO water vending machines in your area are a complete crap-shoot, and 1/3 of all those tested failed to meet safe standard with regard to chemicals. In fact, a lot of the water tested exceeded the state recommended levels for trihalomethanes, which are a byproduct from treating water with CHLORINE. WHAT? Chlorine in your RO water? SAY IT AIN'T SO!

You're brewing with crappy water. Brew a batch with distilled, make some moderate additions to build up the profile if you like, continue your current sanitation practices, and finally put this behind you.

Again... brewed a batch with distilled water. Same horrible flavor.

Let me say this again:

I BREWED A BATCH WITH DISTILLED WATER. I ADDED ONLY GYPSUM AND I STILL HAVE THE EXACT SAME PROBLEM.

So if it's not an infection, and completely changing the water source didn't solve the problem, what is going on???

Well, I must have missed that in the thread. My eyes glazed over a few times and resorted to skimming. My bad. I just deleted another post I made about water quality, so ignore that too if you saw it.

Just for giggles, and since I don't want to do any work today, can you post the grain bill for the recipe you made with distilled water, along with the amount of sparge and strike water, any additions, and their amounts, that you made to each?

And also, before I jump to conclusions, did you bottle any of the distilled water batch, or just keg it all?

Grain bill:

8 lbs 1.2 oz 2-row

1 lb 1.3 oz Biscuit malt

14.4 oz Munich malt

6.1 oz Crystal 20

3.2 oz Special B

2.5 oz Crystal 40

Total: 10.73 lbs

Hop schedule:

1.00 oz of Mosaic FWH

0.50 oz of Mosaic at 60 min

1.00 oz of Mosaic at 30 min

1.00 oz of Mosaic at 15 min

1.00 oz of Mosaic at 5 min

1.00 oz of Mosaic at flameout

I chilled, racked to a cleaned and sanitized fermenter, and fermented at 64 for four days with a rehydrated packet of US-05. Then I added 2 oz of Mosaic to the fermenter. It sat at about 68 for another week before I cold-crashed it and racked to a cleaned and sanitized keg.

I did not bottle any of the batch.

Personally, I think that recipe would look a lot better exactly the way it is, minus the biscuit and special b. You're going to want a simpler, less complex grain bill when diagnosing the problem. Plus, are you sure the mosaic is a good quality and fresh? If not, that recipe would not come out very well.

No it's not. Normally I wait at least a week to dry hop but the poster that gave me this recipe and water profile said that I should dry-hop it as the krausen began to fall.Also, it sounds like your dry hopping right after pitching, is that true?

I hear you with how frustrating things can be, especially when they keep happening. To regain some confidence, try a good extract kit in a new fermenter with spring water, no additions, 2 packets of dry yeast sprinkled on top, good ferm temps, and bottle half of it. If it comes out good you can start checking things off. If it comes out bad then your effed.

Sent from my SPH-L720 using Home Brew mobile app

The water was distilled water. I used 3.5 gallons of strike water. I added 3 teaspoons of gypsum and 0.3 ml lactic acid. I mashed for an hour at 152. I fly-sparged with 5.4 gallons of water. The sparge water had 3 teaspoons of gypsum and 0.3 ml lactic acid added.

However MrHadack, water profiles and ph adjustments are advanced brewing techniques, and the op has proven many different times he's not ready for that level of brewing. Keep it simple and build from there.

Now, hold up a second. Perhaps because I am joining this thread after months of frustration endured by others I have a bit more optimism, but this seems like an easy fix. A good pH meter will run $80-100. The scale is only $10-20. A quick lesson on how to use the Bru'n water sheet properly and this problem might be solved.

Let me just say... I thinks it's all BS... Here's a summary!

I am absolutely stumped at why my beer continues to taste bad

I took apart the regulator last week and cleaned it. I didn't find a speck of dirt in it

I was at one of my favorite bars last night and had a pint of 101 North's Heroine IPA. I ordered a second one and had to wait for them to change the keg. The second pint tasted weird and had the same flavor profile to it that my beers have

C02? ...Yes, I've tried two different places

I've taken it to a LHBS and a brewpub/LHBS. They said they liked it and didn't taste anything wrong.

So sorry it wasn't what you were looking for. Maybe you feel better wasting someone's time with your useless post.

I didn't change the buckets - the beer was great out of the fermentor, but every piece of plastic that touched the beer post-fermentation was replaced. The list is pretty short - the only plastic or rubber pieces that the beer touches are the autosiphon and the keezer lines. Both of which I already replaced while trying to track this problem down.

I really think that the keg cleaning issue was it. The dry-hopping issue is separate from what I can tell. Now, the beers I make that aren't dry-hopped are coming out really good.

Water tastes fine. It's not the water

All equipment has been replaced

I've replaced everything multiple times

Oh I forgot to mention. I bleach bombed all my fermenters.

But since my batches are now coming out of the fermenter tasting bad, I it points me even more toward an infection, but this time I think it's coming from the plastic in the buckets.

In some cases, yes. I have seen white pellicle forming on top of batches

At this point, batches are not tasting good out of the fermenter, either.

^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^

This stuff aint really that hard but you seem to find a way to make it harder! Or are you just joshing...

Since I don't know you... I would swear we are all being punk'd and you are just off your rocker...but I don't know you and maybe you seriously need a new hobby.. No offense!

Cheers!

LovesIPA, one of the big take-aways here is that additions to the water should vary greatly depending upon the style of beer you're brewing as well as the types of grain you're using. Roasted grains and crystal malts are acidic and will drive down the pH of the mash. You have a few of those in the recipe you just posted, which is partly why your pH dropped so low.

The way to use the spreadsheet is to enter your grain bill on the "mash acidification" tab, including the Lovibond number for each grain, as well as whether it is a base malt, crystal, or roast. The sheet will then be able to predict the pH of the mash properly. Once you see what the distilled water and grain is without any additions, you can use the sheet to add various additions to get the Ca and Sulfates where you want them, while making sure the pH hits the number you want.

Additionally, sparge water should be under 6 pH. That's why the sheet calculates it separately and also has a tab dedicated to the sparge acidity. Tannin extraction is MOST dependent upon the pH of the water, not the gravity or the temperature. That's why in my recommendations above, the only place I needed to add the lactic acid was to the sparge water.

I have attached two PDFs of the Bru'n Water Spreadsheet with your grain bill and recipe entered for a 100% distilled water batch. I entered all the additions I recommended above so you can see how everything works out on paper.

Great post MrHadack. You have gone above and beyond sir.

Enter your email address to join: