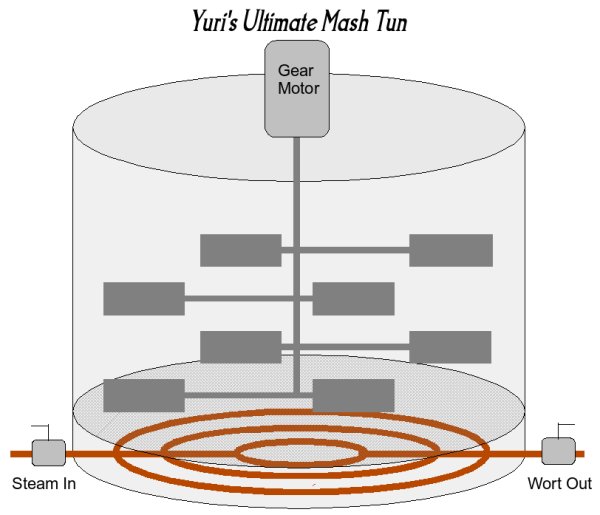

I was tossing and turning last night because I had this idea, so I drew it up this afternoon:

I'd use a 20 gallon brew kettle as the basis for the project. In the bottom sits a copper manifold of concentric rings with two valves attached - one to allow steam injection, the other for wort recirculation and collection.

The manifold would sit underneath a perforated stainless false bottom. Why a false bottom? I want the most even grain bed possible. Also, with my current perforated false bottom, I get a handful of grain "stragglers" through it and into the wort. I think the combination of a false bottom and manifold will really work nicely.

On top of the whole deal is a slow turning gear motor with stirring paddles attached. On one of the paddles somewhere in the middle, I'd attach a temperature sensor (the wired connection at the top would have to be able to spin, but that's not tough).

Everything will be computer controlled through the software I've been writing off and on for the past 6-9 months.

Maximum flexibility is the idea here - a multi-purpose manifold, even heating, stirring, the ability to direct fire...

SWMBO hates when I have these ideas...I can't let them rest until I build them...

What do y'all think?

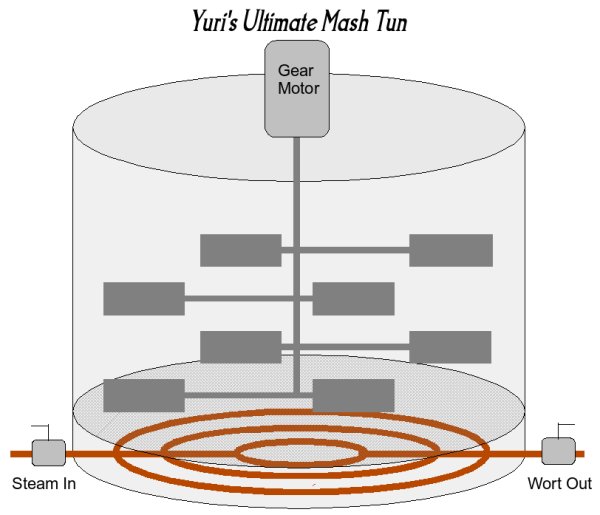

I'd use a 20 gallon brew kettle as the basis for the project. In the bottom sits a copper manifold of concentric rings with two valves attached - one to allow steam injection, the other for wort recirculation and collection.

The manifold would sit underneath a perforated stainless false bottom. Why a false bottom? I want the most even grain bed possible. Also, with my current perforated false bottom, I get a handful of grain "stragglers" through it and into the wort. I think the combination of a false bottom and manifold will really work nicely.

On top of the whole deal is a slow turning gear motor with stirring paddles attached. On one of the paddles somewhere in the middle, I'd attach a temperature sensor (the wired connection at the top would have to be able to spin, but that's not tough).

Everything will be computer controlled through the software I've been writing off and on for the past 6-9 months.

Maximum flexibility is the idea here - a multi-purpose manifold, even heating, stirring, the ability to direct fire...

SWMBO hates when I have these ideas...I can't let them rest until I build them...

What do y'all think?