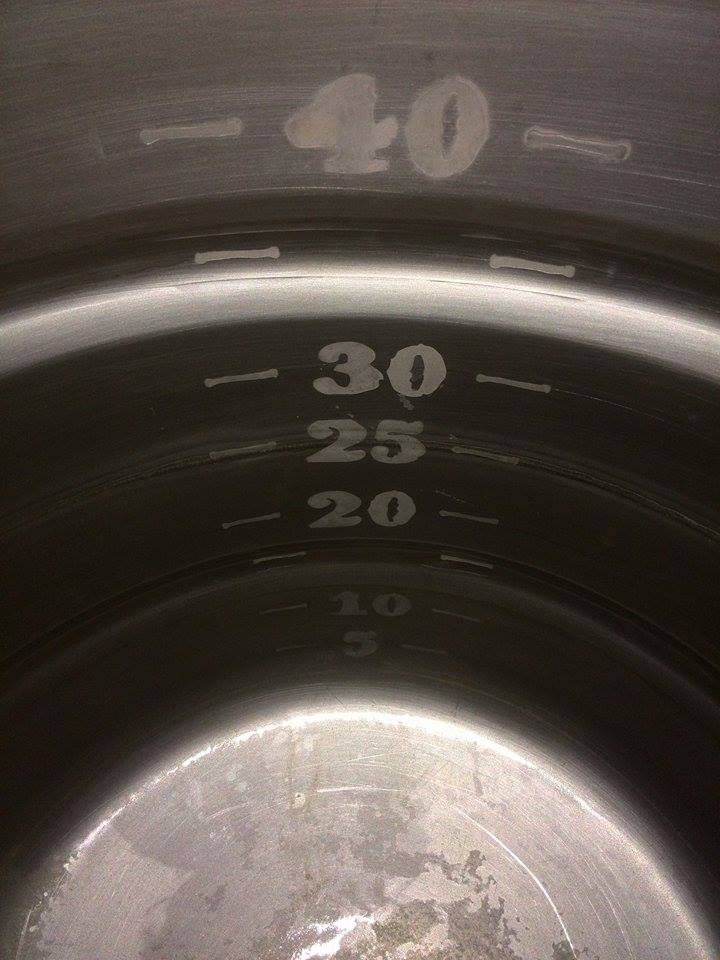

Couple questions. I have been guesstimating and not really stressing volumes for the past few years of brewing. Thinking I should put accurate markings on my BK and see how off I really am.

What are you all using as an accurate 1 Gallon measure? I know I am probably being ridiculous but if I am going to go to the trouble of making sure it is level and marking it I want to be as accurate as I can. Kitchen measuring cup? Filling by weight?

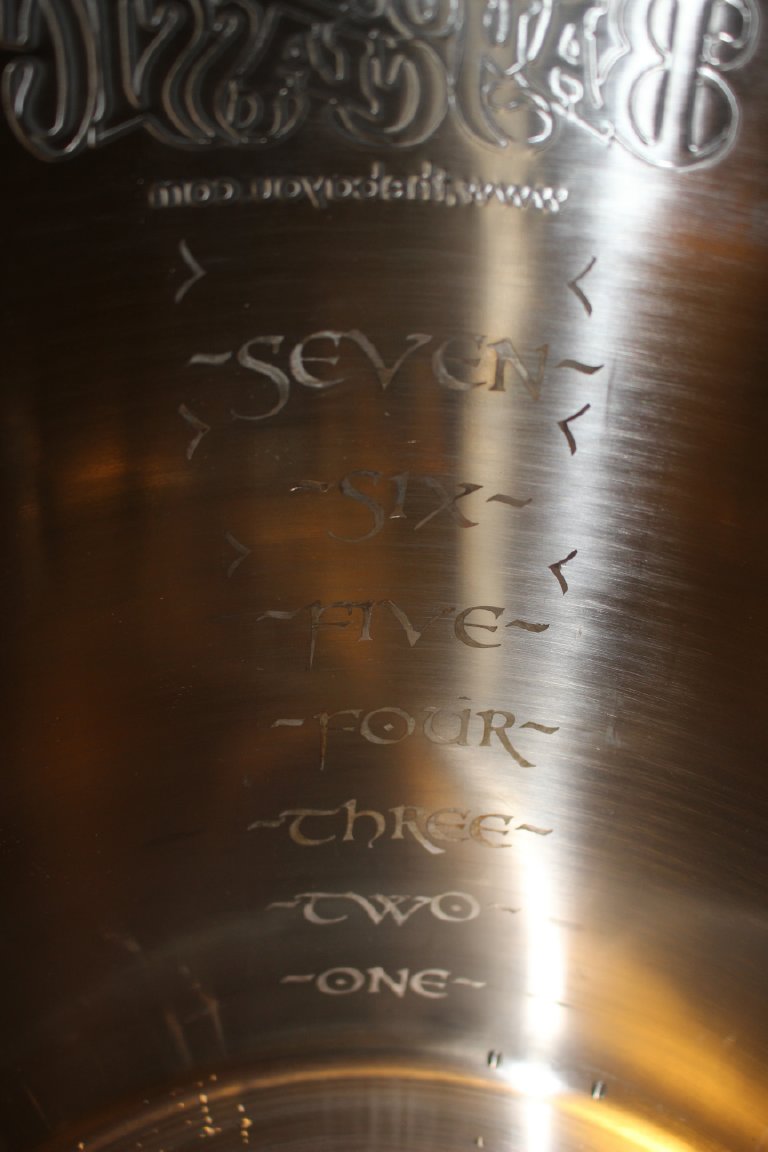

When making marks before etching, how are you doing this? Sharpie? Once again with a retentitive attention to detail in mind on this project drawing a water line on a wet surface is not exactly easy.

I have yet to do it but plan to measure with a gallon measuring cup I purchased a while back. You can use a pencil to mark, or crayon I believe.