I think you brewed about 4 days ago? If it was kept warm, it may have done most of it's ferementing. Strain it from one bucket to another, call it 'secondary'. You can taste it now too. Or, drink enough by straining it through your mustache to get toasted, if that is your point.

It will taste a lot like the finished product now, but be flat, and a little harsh- ageing will help that. What are your plans for bottling/kegging? Or drink it flat?

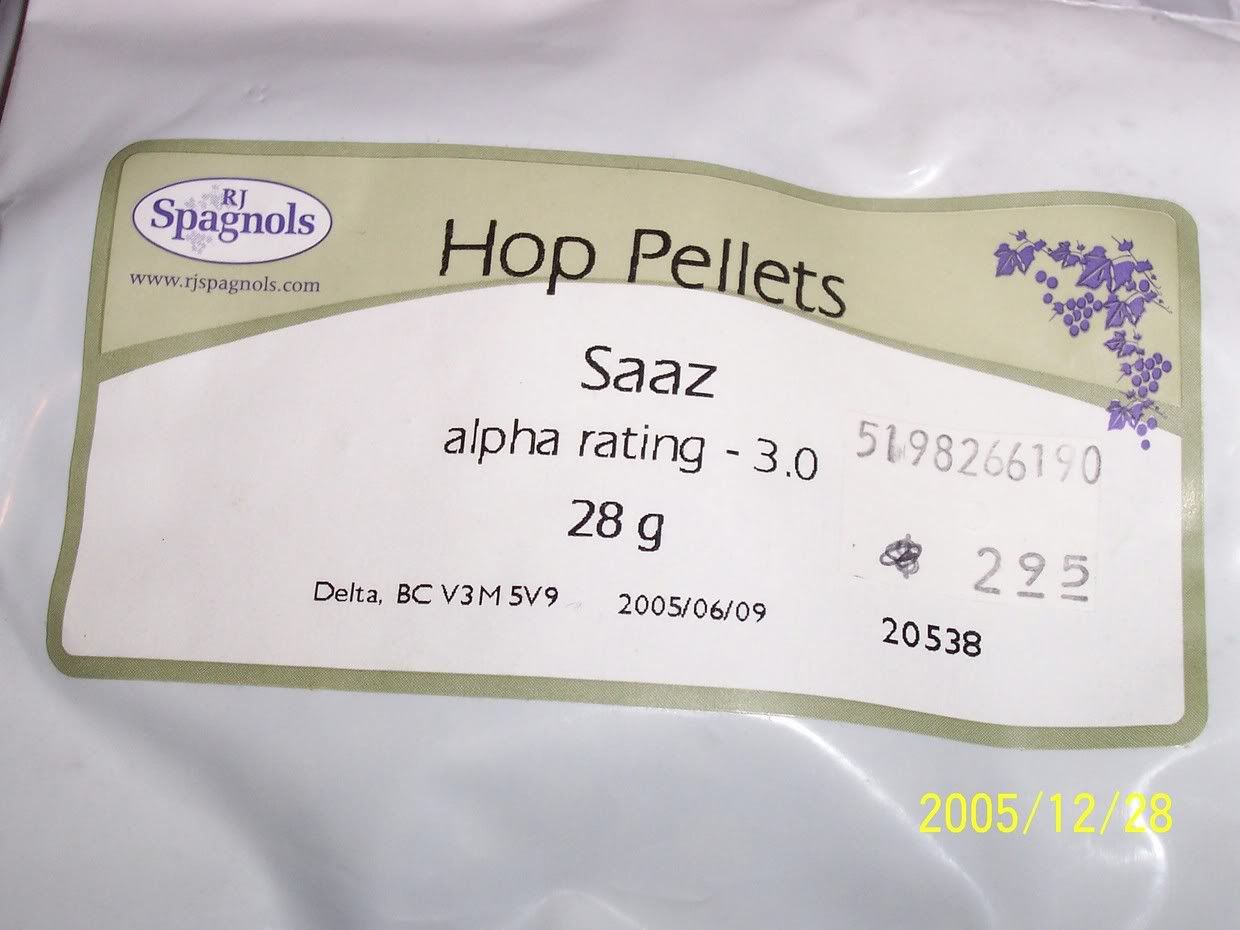

Making good beer doesn't seem to have been your point, making cheap, learning to brew, general tinkering around seeems to be your way of having fun... I'll drink to that! I would have tried your recipe years ago, if I had access to a farm full of barley!