kaffeenjunkie

Well-Known Member

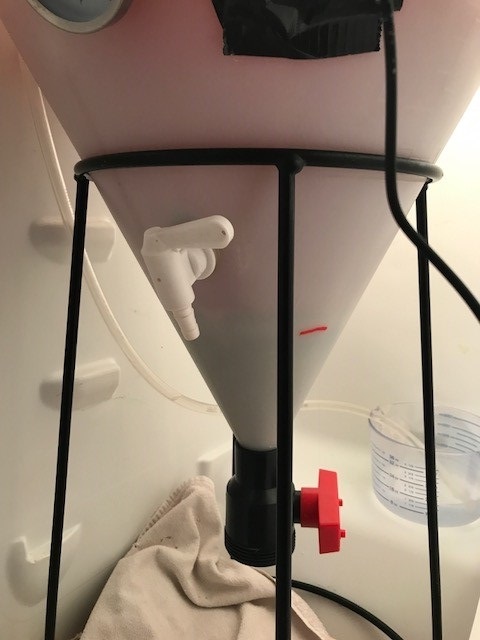

So I received my new FF today.

They are the next generation from my previous ones. I have to hand it to the folks at FF, they are listening and improving their product.

I like the new lid design. The little grooves molded into it seem to make it easier to grip when opening or tightening. I wish I could get one for my othe r old one.

The new, smaller diameter hose, attachment and clip are nice!

The clip actually will stop the flow. I have always been a bit anxious about the old hose introducing too much air. Stopping the flow, was not going to happen with the old clip and hose. It also will not work with the standard bottle fillers without some jury rigging. I will also have to get a bit longer hose to reach the bottom of my keg. I don't care, I keg and I am excited to try the new set up.

Jury's still out on the new round gasket. One thing for sure, it doesn't fall out. I put it in place and shook the heck out of the lid and it stayed in place.

I have had no real issues with the doubled up flat silicone gaskets I currently use.

It also appears that they have left a wider lip on the mouth so things will seal better. Might be just my imagination.

Overall, I like the improvements I see. As they say, the proof is in the pudding I mean, brewing.

Insert the usual disclaimers here; unsolicited, no affiliation, ya dee yah.

They are the next generation from my previous ones. I have to hand it to the folks at FF, they are listening and improving their product.

I like the new lid design. The little grooves molded into it seem to make it easier to grip when opening or tightening. I wish I could get one for my othe r old one.

The new, smaller diameter hose, attachment and clip are nice!

The clip actually will stop the flow. I have always been a bit anxious about the old hose introducing too much air. Stopping the flow, was not going to happen with the old clip and hose. It also will not work with the standard bottle fillers without some jury rigging. I will also have to get a bit longer hose to reach the bottom of my keg. I don't care, I keg and I am excited to try the new set up.

Jury's still out on the new round gasket. One thing for sure, it doesn't fall out. I put it in place and shook the heck out of the lid and it stayed in place.

I have had no real issues with the doubled up flat silicone gaskets I currently use.

It also appears that they have left a wider lip on the mouth so things will seal better. Might be just my imagination.

Overall, I like the improvements I see. As they say, the proof is in the pudding I mean, brewing.

Insert the usual disclaimers here; unsolicited, no affiliation, ya dee yah.