Hello all so I'm in the process in piecing together the parts to build a motorized mill. And I can't get a brand new motor for a steal. Only problem is it's 2hp. I know that's over kill. But will it even work for what I'm trying to do I'm obviously gonna have it geared down from 1700rpm to about 500-600. Any help is greatly appreciated. Cheers!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY motorized grain mill motor question

- Thread starter jstebell

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ebstauffer

Well-Known Member

Are you using sheaves or gear reducer? How about some details on the motor. I opted for a (relatively) cheap chinese one from Global Industrial. Mine was about $140 for 1HP with 56C face. Is the motor 110 or 220 volt? If the former its going to pull about 15 amps, just fyi.

Are you using sheaves or gear reducer? How about some details on the motor. I opted for a (relatively) cheap chinese one from Global Industrial. Mine was about $140 for 1HP with 56C face. Is the motor 110 or 220 volt? If the former its going to pull about 15 amps, just fyi.

I was planning on running with sheaves just to save money really. I don't have the info in front of me right now but I do know that it is 110volt. I'll get the info when I get home. I actually just found a 1/2hp general duty motor on harbor freight. Only 100$ http://m.harborfreight.com/12-hp-general-purpose-electric-motor-67839.html would this be a better option? Thanks.

Subbed. I'd like to motorize my monster mill too. Just unsure how to proceed.

hiflying31

Member

- Joined

- Dec 3, 2013

- Messages

- 16

- Reaction score

- 1

I am just about done building my Mill I used the 1/2hp general duty motor from harbor freight. works great I can fill my Hopper and then turn it on and it powers though the grain, I use pulleys 1 1/2 in on the motor and 11 in on my Mill I used the jsp with gear driver I have one issue I am losing a little bit of grain out the back by the pulley due to my bucket dose not go all the way back I think I am going to add like a chute under the mill

hiflying31

Member

- Joined

- Dec 3, 2013

- Messages

- 16

- Reaction score

- 1

QUOTE=Wreck99;5913632]Subbed. I'd like to motorize my monster mill too. Just unsure how to proceed.[/QUOTE]

I used this to help me with getting started

http://byo.com/component/k2/item/1166-motorize-your-grain-mill-projects

I used this to help me with getting started

http://byo.com/component/k2/item/1166-motorize-your-grain-mill-projects

Thanks! Sadly I'm not as mechanically inclined as some on here, so I'll still need to figure out what I need to buy. I already have the MM2, base, and hopper. Just need to find a motor and whatever other parts I need.

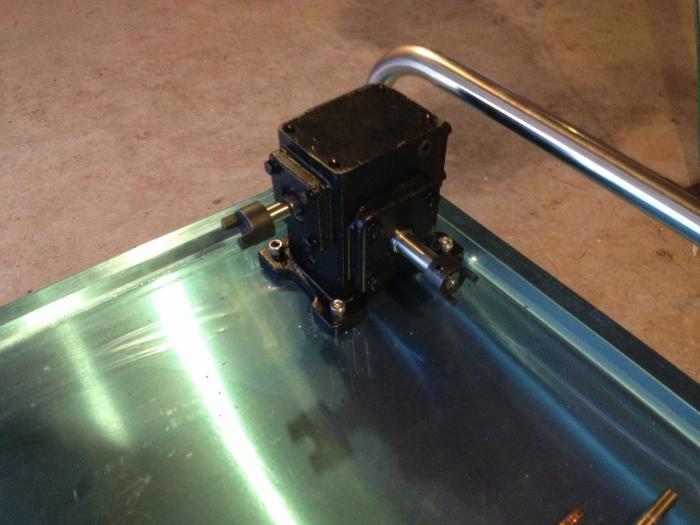

Thanks for the replies. I'm going with the 1/2 hp motor from harbor freight. And i was planning on running pulleys but I ended up ordering a 10:1 reducer from surplus center. Only 89$ plus I like the idea of no pulleys to get caught up in as I'm already buzzed by the time I start milling my grain on brew days. I'm gonna mount it all on a stainless steel cart so I can have some mobility. I will post pics as the parts start to come together. Thank yall. Cheers!!

ebstauffer

Well-Known Member

I'm in the midst of my build now. Here's the current item list: http://goo.gl/CyvqhA

Someone posted a link to this in another thread here. No relation to the seller, but I'm really considering purchasing:

https://www.powergrinder.org/

https://www.powergrinder.org/

hiflying31

Member

- Joined

- Dec 3, 2013

- Messages

- 16

- Reaction score

- 1

that is a great deal

Sent from my SAMSUNG-SGH-I747 using Home Brew mobile app

Sent from my SAMSUNG-SGH-I747 using Home Brew mobile app

Here's my BOM. Minus my mill which I already have. It's a barley crusher w the 7# hopper which I'm about to upgrade with a custom 50# hopper for my 1bbl brews.

1: 1/2 hp general duty motor - 99.99$

http://m.harborfreight.com/12-hp-general-purpose-electric-motor-67839.html

1: 10:1 gear reducer - 92.95$

http://www.surpluscenter.com/Power-...R-REDUCER-0-77-HP-LEFT-OUTPUT-13-133-10-L.axd

2: 5/8" L-050 Jaw coupling half aka Lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/5-8-L-050-JAW-COUPLING-HALF-1-3419-G.axd

1: 3/8" L-050 Jaw coupling half aka lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/3-8-L-050-JAW-COUPLING-HALF-1-3419-C.axd

1: 1/2" L-050 Jaw coupling half aka Lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/1-2-L-050-JAW-COUPLING-HALF-1-3419-E.axd

2: L-050 spacers - 1.80$ each

http://www.surpluscenter.com/Power-...-N-INSERT-FOR-L-050-JAW-COUPLING-1-3419-X.axd

1: Stainless Steel cart 76.75$

http://www.webstaurantstore.com/cho...-utility-cart-33-3-4-x-21-x-37/922T20020.html

Total price 284.54$

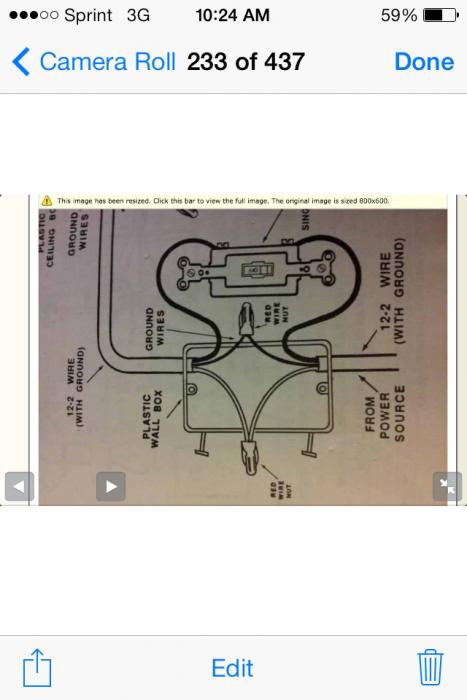

Not including the electrical parts from HD to wire in a switch. Ill post a pic of the wiring diagram I used to wire my chuggars to switches. I can't take credit for it tho. I found it on here at least a year ago. It's very simple even I had no problem figuring it out. Props to who ever posted it. It's helped me out numerous times. Hope this helps some one out.

Now all I have to do is wait to get off the darn business trip so I can start building.

Cheers yall

1: 1/2 hp general duty motor - 99.99$

http://m.harborfreight.com/12-hp-general-purpose-electric-motor-67839.html

1: 10:1 gear reducer - 92.95$

http://www.surpluscenter.com/Power-...R-REDUCER-0-77-HP-LEFT-OUTPUT-13-133-10-L.axd

2: 5/8" L-050 Jaw coupling half aka Lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/5-8-L-050-JAW-COUPLING-HALF-1-3419-G.axd

1: 3/8" L-050 Jaw coupling half aka lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/3-8-L-050-JAW-COUPLING-HALF-1-3419-C.axd

1: 1/2" L-050 Jaw coupling half aka Lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/1-2-L-050-JAW-COUPLING-HALF-1-3419-E.axd

2: L-050 spacers - 1.80$ each

http://www.surpluscenter.com/Power-...-N-INSERT-FOR-L-050-JAW-COUPLING-1-3419-X.axd

1: Stainless Steel cart 76.75$

http://www.webstaurantstore.com/cho...-utility-cart-33-3-4-x-21-x-37/922T20020.html

Total price 284.54$

Not including the electrical parts from HD to wire in a switch. Ill post a pic of the wiring diagram I used to wire my chuggars to switches. I can't take credit for it tho. I found it on here at least a year ago. It's very simple even I had no problem figuring it out. Props to who ever posted it. It's helped me out numerous times. Hope this helps some one out.

Now all I have to do is wait to get off the darn business trip so I can start building.

Cheers yall

Here's my BOM. Minus my mill which I already have. It's a barley crusher w the 7# hopper which I'm about to upgrade with a custom 50# hopper for my 1bbl brews.

1: 1/2 hp general duty motor - 99.99$

http://m.harborfreight.com/12-hp-general-purpose-electric-motor-67839.html

1: 10:1 gear reducer - 92.95$

http://www.surpluscenter.com/Power-...R-REDUCER-0-77-HP-LEFT-OUTPUT-13-133-10-L.axd

2: 5/8" L-050 Jaw coupling half aka Lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/5-8-L-050-JAW-COUPLING-HALF-1-3419-G.axd

1: 3/8" L-050 Jaw coupling half aka lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/3-8-L-050-JAW-COUPLING-HALF-1-3419-C.axd

1: 1/2" L-050 Jaw coupling half aka Lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/1-2-L-050-JAW-COUPLING-HALF-1-3419-E.axd

2: L-050 spacers - 1.80$ each

http://www.surpluscenter.com/Power-...-N-INSERT-FOR-L-050-JAW-COUPLING-1-3419-X.axd

1: Stainless Steel cart 76.75$

http://www.webstaurantstore.com/cho...-utility-cart-33-3-4-x-21-x-37/922T20020.html

Total price 284.54$

Not including the electrical parts from HD to wire in a switch. Ill post a pic of the wiring diagram I used to wire my chuggars to switches. I can't take credit for it tho. I found it on here at least a year ago. It's very simple even I had no problem figuring it out. Props to who ever posted it. It's helped me out numerous times. Hope this helps some one out.

Now all I have to do is wait to get off the darn business trip so I can start building.

Cheers yall

1: 1/2 hp general duty motor - 99.99$

http://m.harborfreight.com/12-hp-general-purpose-electric-motor-67839.html

1: 10:1 gear reducer - 92.95$

http://www.surpluscenter.com/Power-...R-REDUCER-0-77-HP-LEFT-OUTPUT-13-133-10-L.axd

2: 5/8" L-050 Jaw coupling half aka Lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/5-8-L-050-JAW-COUPLING-HALF-1-3419-G.axd

1: 3/8" L-050 Jaw coupling half aka lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/3-8-L-050-JAW-COUPLING-HALF-1-3419-C.axd

1: 1/2" L-050 Jaw coupling half aka Lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/1-2-L-050-JAW-COUPLING-HALF-1-3419-E.axd

2: L-050 spacers - 1.80$ each

http://www.surpluscenter.com/Power-...-N-INSERT-FOR-L-050-JAW-COUPLING-1-3419-X.axd

1: Stainless Steel cart 76.75$

http://www.webstaurantstore.com/cho...-utility-cart-33-3-4-x-21-x-37/922T20020.html

Total price 284.54$

Not including the electrical parts from HD to wire in a switch. Ill post a pic of the wiring diagram I used to wire my chuggars to switches. I can't take credit for it tho. I found it on here at least a year ago. It's very simple even I had no problem figuring it out. Props to who ever posted it. It's helped me out numerous times. Hope this helps some one out.

Now all I have to do is wait to get off the darn business trip so I can start building.

Cheers yall

Here's my BOM. Minus my mill which I already have. It's a barley crusher w the 7# hopper which I'm about to upgrade with a custom 50# hopper for my 1bbl brews.

1: 1/2 hp general duty motor - 99.99$

http://m.harborfreight.com/12-hp-general-purpose-electric-motor-67839.html

1: 10:1 gear reducer - 92.95$

http://www.surpluscenter.com/Power-...R-REDUCER-0-77-HP-LEFT-OUTPUT-13-133-10-L.axd

2: 5/8" L-050 Jaw coupling half aka Lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/5-8-L-050-JAW-COUPLING-HALF-1-3419-G.axd

1: 3/8" L-050 Jaw coupling half aka lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/3-8-L-050-JAW-COUPLING-HALF-1-3419-C.axd

1: 1/2" L-050 Jaw coupling half aka Lovejoy - 3.75$

http://www.surpluscenter.com/Power-...lers/1-2-L-050-JAW-COUPLING-HALF-1-3419-E.axd

2: L-050 spacers - 1.80$ each

http://www.surpluscenter.com/Power-...-N-INSERT-FOR-L-050-JAW-COUPLING-1-3419-X.axd

1: Stainless Steel cart 76.75$

http://www.webstaurantstore.com/cho...-utility-cart-33-3-4-x-21-x-37/922T20020.html

Total price 284.54$

Not including the electrical parts from HD to wire in a switch. Ill post a pic of the wiring diagram I used to wire my chuggars to switches. I can't take credit for it tho. I found it on here at least a year ago. It's very simple even I had no problem figuring it out. Props to who ever posted it. It's helped me out numerous times. Hope this helps some one out.

Now all I have to do is wait to get off the darn business trip so I can start building.

Cheers yall

How is everything working out? Would love to see pics.

Someone posted a link to this in another thread here. No relation to the seller, but I'm really considering purchasing:

https://www.powergrinder.org/

Probably going to order this motor. Anyone have personal reviews on it?

Owly055

Well-Known Member

- Joined

- Feb 28, 2014

- Messages

- 3,008

- Reaction score

- 686

The Two HP motor is a bit absurd.......... but a motor draws only as many amps as the load it is pulling... except during startup. An honestly rated motor...... and most of them are NOT honestly rated, will draw about 12 amps per HP on 115VAC....If they rate is at much less, they are flat out lying. 10 would be a more typical value... but it's less than honest. That draw is at full rated load. A two hp motor will draw SLIGHTLY more than a 1 hp motor at the same load as a rule....but not very darn much. "Compressor Duty" motors are absurdly over rated....... their numbers are a flat out lie.

If you are looking for motors at Harbor Freight......... look at tools with motors on them.... I've seen cases where a tool with an induction motor is cheaper than a stand alone motor!

H.W.

If you are looking for motors at Harbor Freight......... look at tools with motors on them.... I've seen cases where a tool with an induction motor is cheaper than a stand alone motor!

H.W.

Anybody ever consider setting up a rolling mill using bicycle parts? For the short time period you use it, it would make sense, and be one of a kind.

HBTers didn't just fall off a turnip truck. They've been there and done that - almost always

Cheers!

The Two HP motor is a bit absurd.......... but a motor draws only as many amps as the load it is pulling... except during startup. An honestly rated motor...... and most of them are NOT honestly rated, will draw about 12 amps per HP on 115VAC....If they rate is at much less, they are flat out lying. 10 would be a more typical value... but it's less than honest. That draw is at full rated load. A two hp motor will draw SLIGHTLY more than a 1 hp motor at the same load as a rule....but not very darn much. "Compressor Duty" motors are absurdly over rated....... their numbers are a flat out lie.

If you are looking for motors at Harbor Freight......... look at tools with motors on them.... I've seen cases where a tool with an induction motor is cheaper than a stand alone motor!

H.W.

It says 1/2 HP.

"Power Grinder is a 1/2 hp, 110 volt, capacitor start, reversible, 400 watt, single phase electric brute of a grain mill motor, coupled with an armoured gear reducer which will power your home brew grain mill at one of two ideal grinding speeds*. with the appropriate hardware (sold seperately) this monster will chew through your grain in seconds!"

Owly055

Well-Known Member

- Joined

- Feb 28, 2014

- Messages

- 3,008

- Reaction score

- 686

Somebody beat me to the punch............ I guess I'll have to try the "original idea" of using water power ;-)................. I have an irrigation ditch in the back yard that runs a strong stream most of the summer, and have been threatening for years to build an undershot wheel........ Oops.... I'm a few hundred years too late!! Here we get a LOT of wind, but that would be a bit more complicated to use.

My favorite idea was the "Cyclovision"......... a sofa with pedals and a generator. The family would have to pedal to watch TV. I talked about it for years, and someone else finally designed and built one...... of course! I'm a NON_TV guy........... Never had a TV in my life..... the ultimate time waster!!

H,W.

My favorite idea was the "Cyclovision"......... a sofa with pedals and a generator. The family would have to pedal to watch TV. I talked about it for years, and someone else finally designed and built one...... of course! I'm a NON_TV guy........... Never had a TV in my life..... the ultimate time waster!!

H,W.

HBTers didn't just fall off a turnip truck. They've been there and done that - almost always

Cheers!

Airplanedoc

Well-Known Member

Anybody ever consider setting up a rolling mill using bicycle parts? For the short time period you use it, it would make sense, and be one of a kind.

H.W.

Go ahead and build one... I looked at the videos, people have built one, but I have never seen grain milled with one. Just pedaling the bike and turning a unloaded mill. Post up.....

Owly055

Well-Known Member

- Joined

- Feb 28, 2014

- Messages

- 3,008

- Reaction score

- 686

Go ahead and build one... I looked at the videos, people have built one, but I have never seen grain milled with one. Just pedaling the bike and turning a unloaded mill. Post up.....

I have some ideas.......... thinking about it. I pay $1.75 per pound for grain from my LHBS, which is 80 miles from home. I can buy base malt from the local micro brewery where I am a regular customer, and bring him kombucha frequently......At $33.00 a for a bag of two row. He buys by the pallet....... 2.5 times as much retail......... and the micro brewery is 30 miles closer. The big thing is being able to have it on the shelf, and mill it as I use it. Right now I have about 10 lbs of msc malt on hand that's milled already. I've got to use it fairly soon.

H.W.

So I got tired of waiting to get the mill built before I brew so I'm brewing with the old setup. Here's a pic. I'm brewing a wake n bake clone. It's an imperial oatmeal coffee stout made by Terriapan here in Athens.

Stealthcruiser

Well-Known Member

Terrapin's got some good stuff!

BBL_Brewer

Well-Known Member

I know the OP already has a motor picked out, but for anyone that's interested you can find some great used motors at the local scrap yard for next to nothing. I got a 1/4 horse 1750 RPM motor that was in really good shape for $3. There's no warranty of course, but if it's no good you can sell it back and grab another one. I got lucky and picked a good one that was exactly what I needed on my first visit. Beats paying $50 or more for a brand new one. I think the last time I looked at a similar new motor at Rural King ( a farming supply chain with descent prices), it was $68.

I know the OP already has a motor picked out, but for anyone that's interested you can find some great used motors at the local scrap yard for next to nothing. I got a 1/4 horse 1750 RPM motor that was in really good shape for $3. There's no warranty of course, but if it's no good you can sell it back and grab another one. I got lucky and picked a good one that was exactly what I needed on my first visit. Beats paying $50 or more for a brand new one. I think the last time I looked at a similar new motor at Rural King ( a farming supply chain with descent prices), it was $68.

I wish I woulda thought of that. Coulda saved 100$ or so. Oh well the harbor freight I purchased came with a 2 year warranty so I can't complan. The shipping on the cart supposedly got delayed so it should be here tomorrow. So standby for the build. Cheers!!

drunkenmonk

Well-Known Member

Great approach for your build. Using a gear reducer is the way to go. Belt and sheaves makes the cart more complicated and is just dangerous.

I've had mixed results with the Barley Crusher. My idle roller kept sticking and I was always cleaning gunk out of the bushings and lubricating them. I upgraded to Monster Mill which is a little beefier.

Sent from my iPad using Home Brew

I've had mixed results with the Barley Crusher. My idle roller kept sticking and I was always cleaning gunk out of the bushings and lubricating them. I upgraded to Monster Mill which is a little beefier.

Sent from my iPad using Home Brew

sandyeggoxj

Well-Known Member

Where did you order the cart from?

Webstrauntsupply.com I take back what I said earlier. After I reviewedy order I guess I had a brain fart and ordered the smaller of the two. I do have the larger one already on the way. So the build is on stand by. Now I have an extra stainless cart. What to do with it?

Very cool. Looking forward to the final product.

Very cool. Looking forward to the final product.

Thanks a lot. I'm haveing a lil trouble with the wiring. It's going to be more complacted than I originally thought.

Similar threads

- Replies

- 66

- Views

- 9K

- Replies

- 23

- Views

- 3K

- Replies

- 3

- Views

- 871

Latest posts

-

-

-

-

-

-

Munich Helles 2011 1st Place HBT- Light lager- Augustiner Lagerbier Hell

- Latest: eliastheodosis

-