I've had three plastic 15 gal conicals running for 2 years now. I've had all three filled numerous times with two of them fermenting ale temps and one cold crashing. The coldest I've ever gotten down to is about 30-32 in the fermenter but the system struggles. Hits 35 with no problem. The limitation is due to the physics of using a home AC unit.

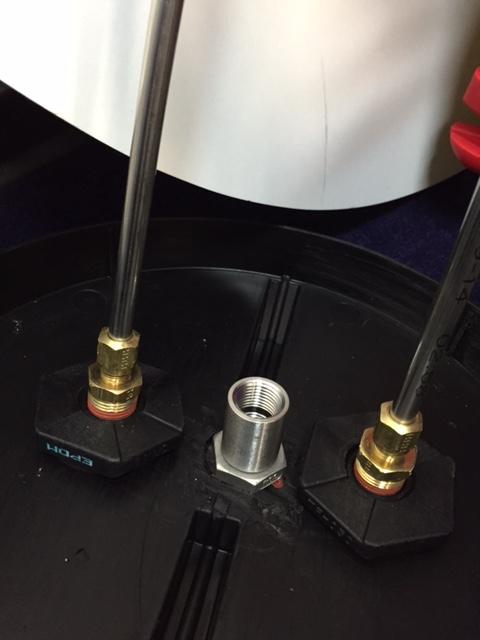

I don't really have any issues with the pumps (good to see you back in the game Packet, learned a ton from you). As long as I make sure it's fed before opening and that I've bled some air, works fine. I'll probably add those ball valve arrangements so I don't have undo the hose and bleed.

Although the plastic worked well for a while, I've been switching over to SS 12.5 gallon conicals. In the past year, I just haven't liked a lot of what we've brewed, off flavors, etc. I think it's because we're not strict enough about our cleaning procedures even though we have a 2" cip spray ball that blows a ton of water. I also never liked the fact that things don't seal all that well and they can't hold pressure. When we clean them, water blasts out the lid and it's a pain. The SS are just much simpler to keep clean. I could rarely ever get rid of the smell of the last brew in the plastics which just never sat well with me.

The chilling system, though, works a charm. It's PID controlled so it really dials in temps. I can also heat with my chilling system. I have a fairly large pump in my glycol cooler. If I run that without the AC going, it will heat up the glycol (found that out the hard way!). If I then set the fermenter for heat control vs cool control in the BCS, I can set a temp and it heats up the fermenter. Last week I had a Saison up to 85 in my 65 basement.

For the money you lay out for a plastic conical with all the bling, it just isn't as cost effective as it used to be given some of the alternatives out there. I was able to use my SS coils in the new fermenters as well as most of the connections on the new ones.

Happy brewing!

mess and dog in the photos haha.

mess and dog in the photos haha.