Would be interested in pricing at least. Would also be interested in knowing your BOM, as I am particularly curious as to your recommendations for the 1-wire terminals and the sound generator attached to GPIO25?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CraftBeerPi - Raspberry Pi Software

- Thread starter chixxi

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

No problem! In the car now but a quick search yields these, as reference. http://m.ebay.com/itm/311375040529?_mwBanner=1

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

Alternately, you can assign whatever open Channel on the 12v rail to your buzzer and use a 12vdc alarm.

May go then latter route with 12V, since it looks like CPB allows you to assign your choice of GPIO to the buzzer function.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

You do you. Boards shipped from manf. Could take up to 4 weeks so when they get here I'll let everyone know individually.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

View attachment ImageUploadedByHome Brew1475665829.799453.jpgheres a picture of the completed 4.1 board from @terragedyView attachment ImageUploadedByHome Brew1475666193.302140.jpgView attachment ImageUploadedByHome Brew1475666209.004025.jpg and here's the board mounted to the pi.

beershralper

Member

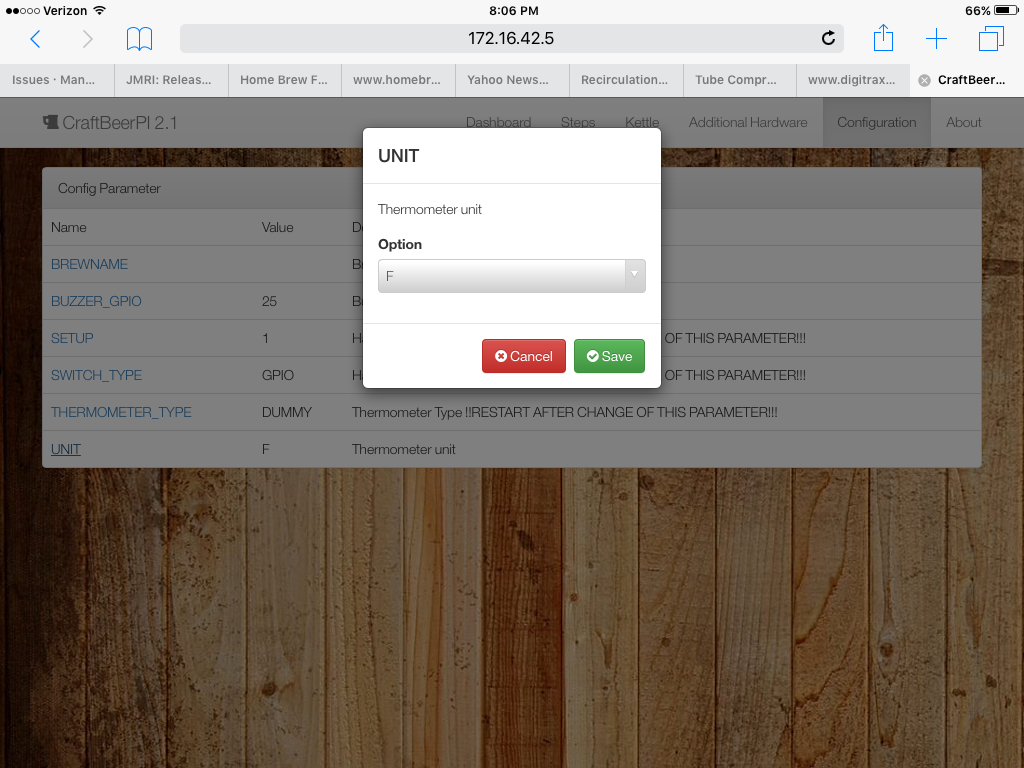

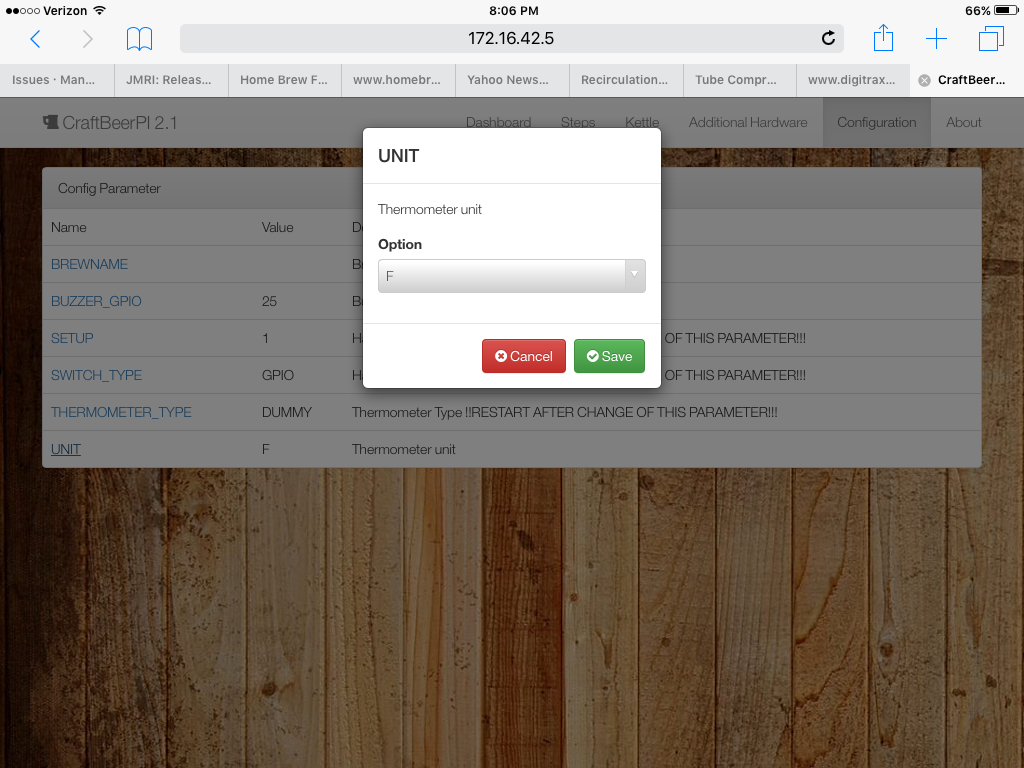

New to Pi and brewing automation and can't seem to figure out how to change the temp from Celsius to Fahrenheit.

Pi3 B v1.2

Craftbeerpi 2.1

Raspibian

Chromium

I have four ds1820 connected.

all programs where uploaded this past monday

thanks

Pi3 B v1.2

Craftbeerpi 2.1

Raspibian

Chromium

I have four ds1820 connected.

all programs where uploaded this past monday

thanks

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

Fairly confident it's in the settings tab. I don't have mine up right now but I was able to change it. Although, doesn't doing a ramp from 40 to 66C sound better than 104 to 154?

Menu\Configuration\unit

In case that wasn't clear, click on the word 'UNIT'; it is a link to the panel where you can select which option, C or F. The link is not underlined until you click on it.

Although, doesn't doing a ramp from 40 to 66C sound better than 104 to 154?

No.

beershralper

Member

For whatever reason, when I select "configuration" the only things that show up are "switch_type" and "thermometer_type". I currently have four probes connected and four kettles set up, all reading correctly.

Though, I did create a few unnamed kettles that I couldn't delete, so i deleted the craftbeerpi.db file.

Though, I did create a few unnamed kettles that I couldn't delete, so i deleted the craftbeerpi.db file.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

Thanks, Manuel. Just sent you the app.log. The setup goes fine, and I can customize my hardware profiles. It recognizes the OneWire probe I have connected. But on the main page, when you should press start to initialize the profile sequence (heating, cooling, wait periods, etc.) based on a particular recipe loaded, nothing happens. Doesn't initialize. And the manual buttons (to activate the heater, or a pump, for instance) do nothing...

Hello there, I am having the exact same problem and I don't see a reply or fix on here. Did you ever get this resolved? If so... what was the fix, Please help!!!

carloswlkr

TheBlindPig

Yes, I did manage to figure it out. It is related to the anti-virus on my laptop. Whenever I access the page, I have to disable Kaspersky. Haven't been able to find what to adjust in the firewall/web attack/antivirus configuration that doesn't seem to like the way the web interface works, but all I know is when I disable it, the system works like a charm.

Thanks for the replyYes, I did manage to figure it out. It is related to the anti-virus on my laptop. Whenever I access the page, I have to disable Kaspersky. Haven't been able to find what to adjust in the firewall/web attack/antivirus configuration that doesn't seem to like the way the web interface works, but all I know is when I disable it, the system works like a charm.

@SHvanBommel:

What is the pitch of the various terminal connector pads on your board? It looks like the 1-wire pads are 5.08mm (twice the pitch of the pi header) and the 12V GPIO pads are 3.5mm. Is that correct?

What is the pitch of the various terminal connector pads on your board? It looks like the 1-wire pads are 5.08mm (twice the pitch of the pi header) and the 12V GPIO pads are 3.5mm. Is that correct?

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

They are 3mm (sparkfun: PRT-10571) and 5mm (sparkfun: PRT-08433). as I put these together there will be refinements to the design. Cheers!

Thanks!

dantodd

Well-Known Member

Funny, I was just going to come and look for the possibility of measuring volume with CraftBeerPi too. I was thinking about using a pressure sensor though. Something like the 5 psi version of this: http://www.ebay.com/itm/New-Pressur...5Ckz3BMsAVA8MA&item=272309295111&var=&vxp=mtr

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

that's def. a manuel question.

Funny, I was just going to come and look for the possibility of measuring volume with CraftBeerPi too. I was thinking about using a pressure sensor though. Something like the 5 psi version of this: http://www.ebay.com/itm/New-Pressur...5Ckz3BMsAVA8MA&item=272309295111&var=&vxp=mtr

5 psi is nearly 12 feet of water.

An pressure sensor is an alternative, but since the pressurehight of the kettle is so low i'm unsure if an pressure sensor could give an accurate reading.

In my kettle the pressure at the bottom with filled kettle with water is about 0,5psi. So the pressure differanse at one litre is about 0,013psi.

-Kjenset-

In my kettle the pressure at the bottom with filled kettle with water is about 0,5psi. So the pressure differanse at one litre is about 0,013psi.

-Kjenset-

dantodd

Well-Known Member

5 psi is nearly 12 feet of water.

5 psi is the smallest one they make. I know that it would be less than 1 psi.

Your resolution will stink. There are 1 psi sensors available, but threaded for direct connection are ~$120 new. I would recommend the method I did, which was not too expensive if cost is of concern.

Does everybody use a transistor to get the SSR to work? Anybody just using the GPIO on the PI?

I've got a pot with two heaters in it. 1 x 1500W and 1 x 1000W. How should I wire this?

1. Both on one SSR

2. Two SSR but on the same GPIO

3. Two SSR and two GPIO. One connected to the pot in CBP and on just as an additional hardware. I would have to turn the element on and off whenever I need to use it (to heat it up faster, boiling etc).

In my head, number 1 is the correct way to go. The SSR can handle it.

I've got a pot with two heaters in it. 1 x 1500W and 1 x 1000W. How should I wire this?

1. Both on one SSR

2. Two SSR but on the same GPIO

3. Two SSR and two GPIO. One connected to the pot in CBP and on just as an additional hardware. I would have to turn the element on and off whenever I need to use it (to heat it up faster, boiling etc).

In my head, number 1 is the correct way to go. The SSR can handle it.

Don't connect an SSR directly to a RasPi GPIO pin. You want to buffer the GPIO. The max current the Pi can handle on one pin is 16ma and the max total for all pins combined is 50ma. Depending on your SSR you are likely to exceed the capability of the Pi. Auber specs the Mager SSR they sell at 3ma to 25ma input. I suspect that varies based on the input voltage and output wattage (VA).

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

Googled:

http://www.domoticz.com/forum/viewtopic.php?t=6226

"Hey,

I had the exact same problem with the 4-channel version of the same board. This fixed it for me:

It's solved!!

This did the trick, and everything is working like it should be, include the relais state stay OFF on powerup boot... >

In /etc/init.d/domoticz.sh

sudo sh -c 'echo # > /sys/class/gpio/export'

sudo sh -c 'echo high > /sys/class/gpio/gpio#/direction'

sudo sh -c 'echo 1 > /sys/class/gpio/gpio#/active_low'

Where # is gpio pin.

*Edit The only thing needed to do was to enter the codes all up in the startupscript, domoticz.sh

I was entering it into the latest line, so when domoticz started up it didnt see the gpio ports.

Now it does, and everything works!"

I would think that this would apply in the same way except finding the write script to insert the code and appropriate gpio#

Perhaps @manuel can help with that.

http://www.domoticz.com/forum/viewtopic.php?t=6226

"Hey,

I had the exact same problem with the 4-channel version of the same board. This fixed it for me:

It's solved!!

This did the trick, and everything is working like it should be, include the relais state stay OFF on powerup boot... >

In /etc/init.d/domoticz.sh

sudo sh -c 'echo # > /sys/class/gpio/export'

sudo sh -c 'echo high > /sys/class/gpio/gpio#/direction'

sudo sh -c 'echo 1 > /sys/class/gpio/gpio#/active_low'

Where # is gpio pin.

*Edit The only thing needed to do was to enter the codes all up in the startupscript, domoticz.sh

I was entering it into the latest line, so when domoticz started up it didnt see the gpio ports.

Now it does, and everything works!"

I would think that this would apply in the same way except finding the write script to insert the code and appropriate gpio#

Perhaps @manuel can help with that.

bLazem

Active Member

- Joined

- Jan 19, 2015

- Messages

- 26

- Reaction score

- 8

Googled:

http://www.domoticz.com/forum/viewtopic.php?t=6226

"Hey,

I had the exact same problem with the 4-channel version of the same board. This fixed it for me:

It's solved!!

This did the trick, and everything is working like it should be, include the relais state stay OFF on powerup boot... >

In /etc/init.d/domoticz.sh

sudo sh -c 'echo # > /sys/class/gpio/export'

sudo sh -c 'echo high > /sys/class/gpio/gpio#/direction'

sudo sh -c 'echo 1 > /sys/class/gpio/gpio#/active_low'

Where # is gpio pin.

*Edit The only thing needed to do was to enter the codes all up in the startupscript, domoticz.sh

I was entering it into the latest line, so when domoticz started up it didnt see the gpio ports.

Now it does, and everything works!"

I would think that this would apply in the same way except finding the write script to insert the code and appropriate gpio#

Perhaps @manuel can help with that.

Hey great, thanks for that.

So do I add a line for each of my GPIO pins I want to invert?

Cheers,

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

Seems like it

bLazem

Active Member

- Joined

- Jan 19, 2015

- Messages

- 26

- Reaction score

- 8

Seems like it

Cool, will check that out tonight.

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

I'm not guaranteeing it will work, I'll have to try it myself

carloswlkr

TheBlindPig

Currently the data is stored in-memory only. I will add a simple csv export next days. Then you can import the data into excel or what ever tool you like.

Manuel, did you have a chance to look into exporting the data from memory? I'd like to save my mash data for different batches, but haven't been able to figure it out yet.

Thanks!

Bigdaddyale

Well-Known Member

Has anybody got the 4.1 board up and running yet? I'm still waiting on parts

raining_turtles

Member

- Joined

- Jul 15, 2012

- Messages

- 18

- Reaction score

- 0

Is there any possibility of adding a cooling function to the software. Preferably using a hysteresis method. I'm trying to set up a glycol setup and would help out tremendously.

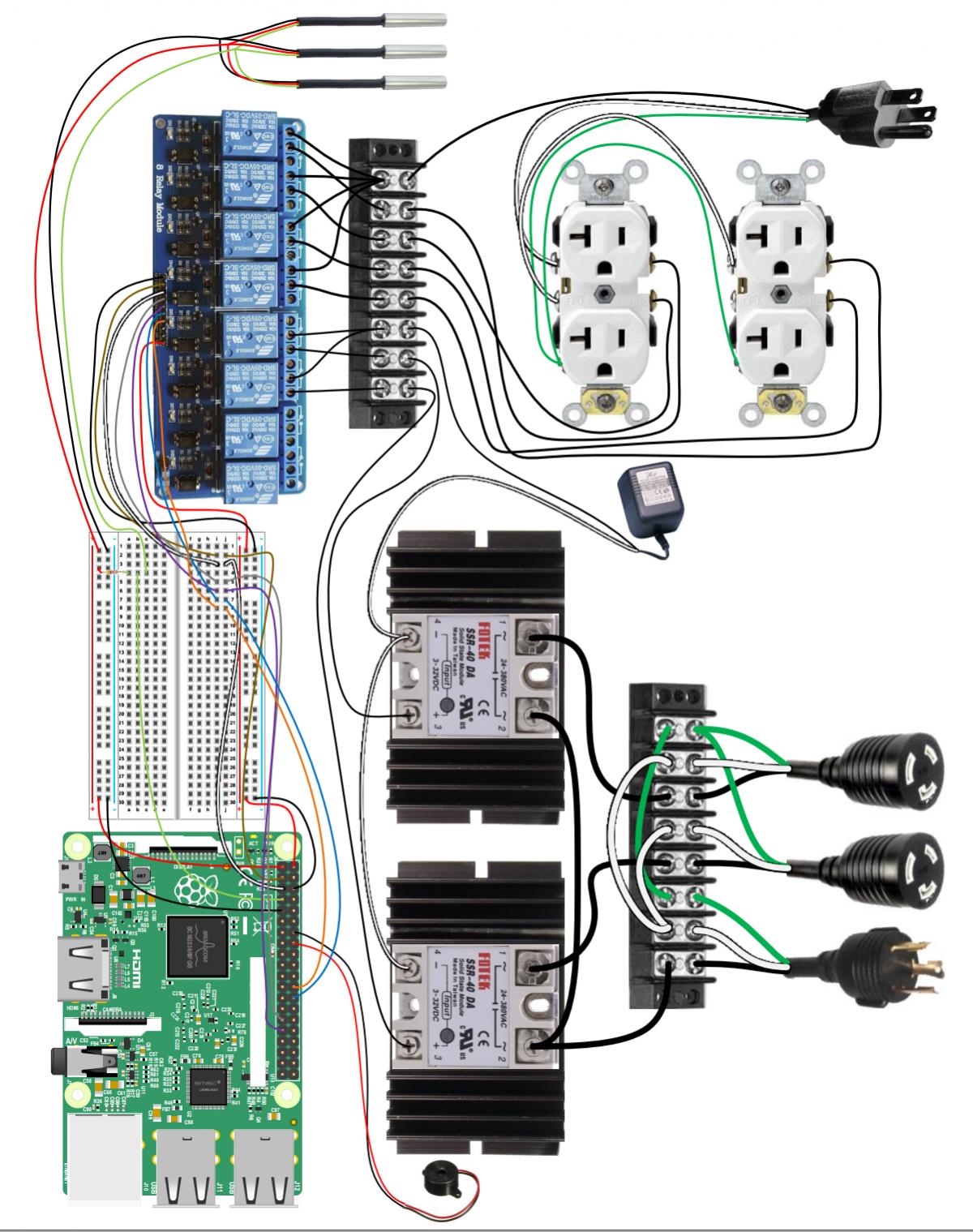

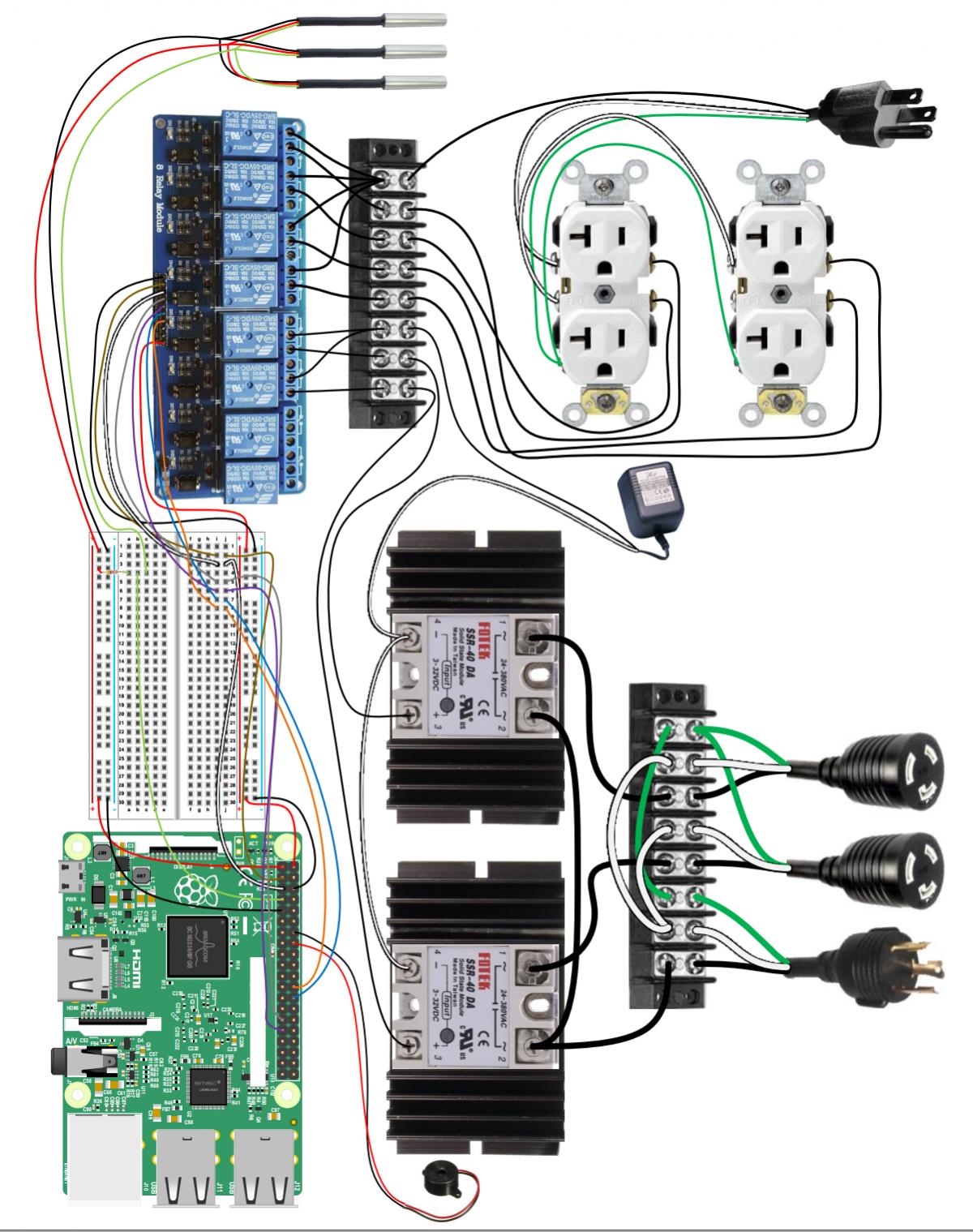

I am having an issue with the rig starting up. I am using a Sainsmart 8-channel relay to run my 110v for pumps and to fire the SSRs for my heaters in a 3-kettle HERMS system. The issue I am having is that when CBPi starts up, it switches all of the relays from low to high (off to on). I can wire the relays so that the load is powered in either the off or on state, but since the default for the RPi is off and the default of CBPi is on, my pumps and heaters are on as soon as I power the RPi until CBPi starts. This is obviously not ideal.

I have tried the solution earlier in the thread to reverse the operation of the relays, but that does not seem to have any effect. I have also tried changing the "hardware control type" from 1 to 0 and back. I'm not sure what this is designed to do, but it does not seem to affect the way the relays work.

My goal would be to keep the relays off and only turn them on when I want to turn on a pump or heater. My only workaround so far is to unplug both the 110v and 220v input until CBPi is running. Any help would be greatly appreciated. A full diagram of my wiring is attached (I can email a full-res PDF if it would help).

I have tried the solution earlier in the thread to reverse the operation of the relays, but that does not seem to have any effect. I have also tried changing the "hardware control type" from 1 to 0 and back. I'm not sure what this is designed to do, but it does not seem to affect the way the relays work.

My goal would be to keep the relays off and only turn them on when I want to turn on a pump or heater. My only workaround so far is to unplug both the 110v and 220v input until CBPi is running. Any help would be greatly appreciated. A full diagram of my wiring is attached (I can email a full-res PDF if it would help).

SHvanBommel

Well-Known Member

- Joined

- Nov 5, 2007

- Messages

- 548

- Reaction score

- 57

^i would consider this a major fault. I'll go and check on my setup (I have switches for on/off/auto and always start in "off" until I start my process.

purdman10

Well-Known Member

I have been following this project with great interest, as it looks like I can use it to automate my 3 keggle propane setup. I have built each version of the teensypi/teensynet projects with not much success, probably because of defects in my knowledge of how things work,so I two questions. From that project, I have built LCD boards that use I2C lines. Can I connect 2 LCD boards to the I2C lines to run my RGB LCDs? Also I have 5v, 5a power supplies. Can I hook one up rather than stepping down from 12 volts?

Similar threads

- Replies

- 15

- Views

- 896

- Replies

- 9

- Views

- 3K

- Replies

- 13

- Views

- 2K

- Replies

- 0

- Views

- 1K