I've been struggling with getting a Pi 4B to recognize some cheap Amazon DS18B20s. I was powering them via 3.3V, and getting the "00-80000000" result in /sys/bus/w1/devices. After scrounging a bit, I found a few references to folks powering them via 5V. Tried it out, and voila, "28-", reading temps, and CraftBeerPi has a kettle sensor once more. So I figured I'd throw this up here to make it easier for someone else to find in the future.

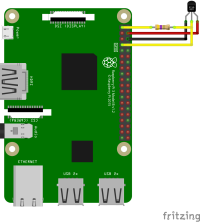

Attached is a wiring diagram of what worked for me (source: A DS18B20 with 5v - Raspberry Pi Forums). Make sure to include the 4.7K pullup resistor between 3.3V and data.

Attached is a wiring diagram of what worked for me (source: A DS18B20 with 5v - Raspberry Pi Forums). Make sure to include the 4.7K pullup resistor between 3.3V and data.