- Joined

- Jan 18, 2011

- Messages

- 3,032

- Reaction score

- 283

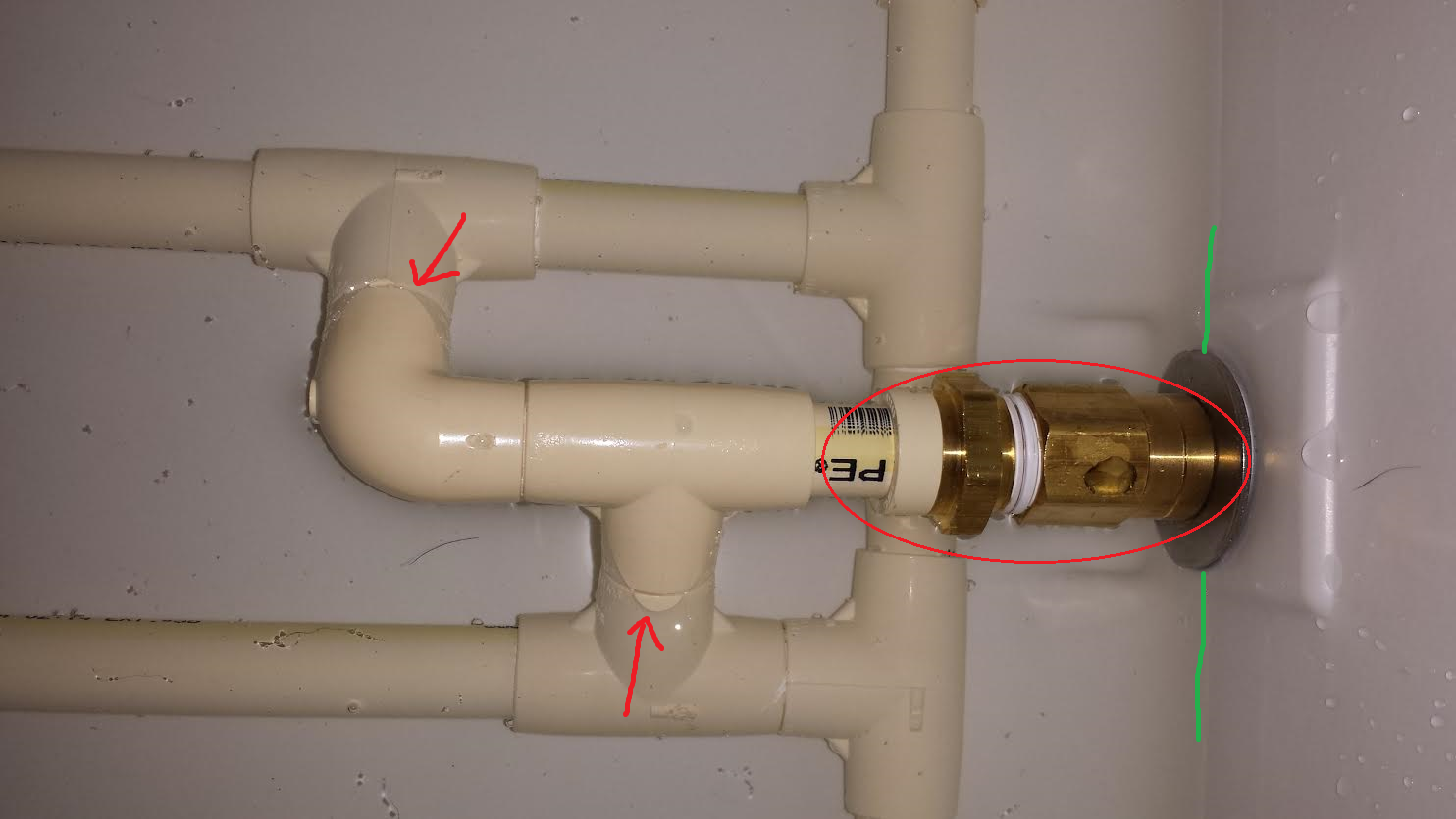

I WISH my slits were that uniform and perfect. I'll upload a photo when I'm done, but some of them are hacked up a bit. I don't think the openings are too big, but maybe they are..

This could get dirty fast...

MC