kc.rkitek

Well-Known Member

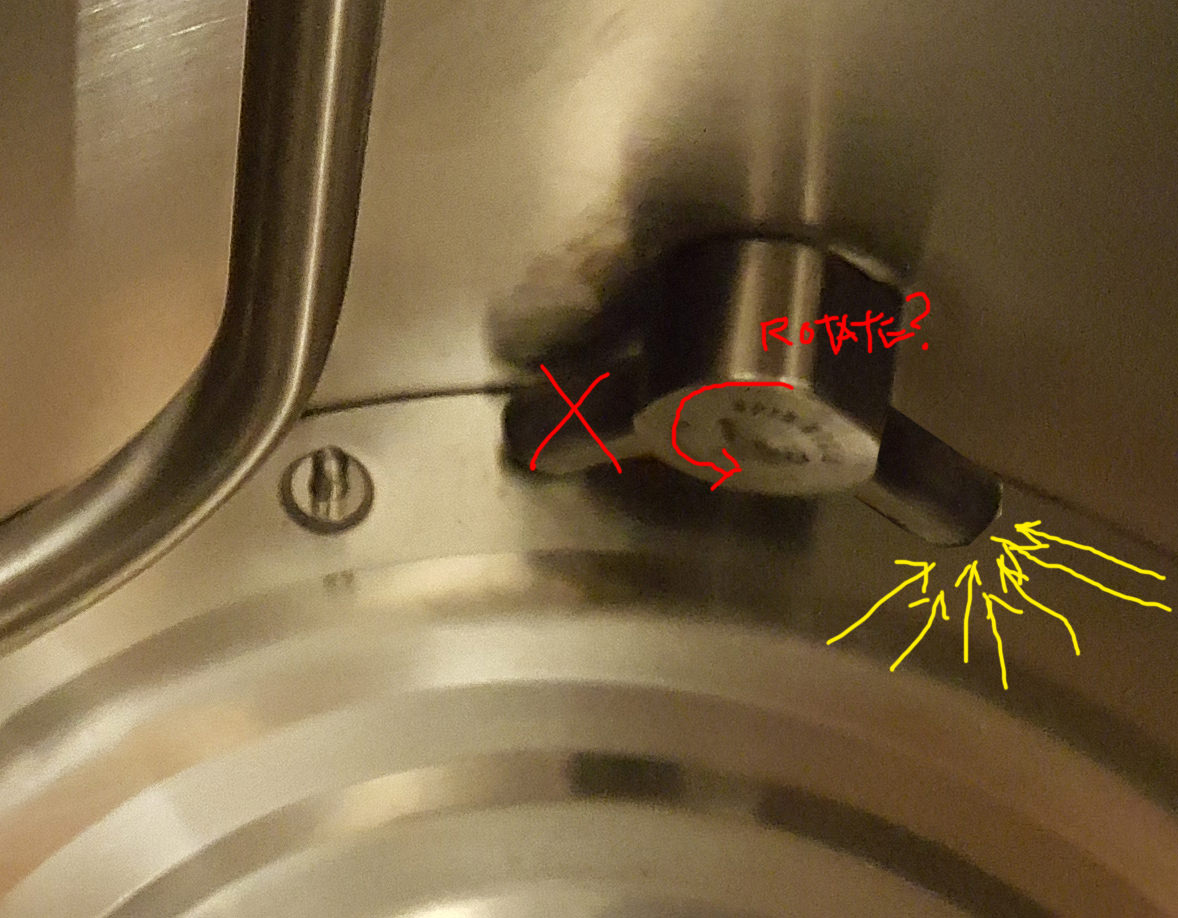

I finally got my M&B last week and have been busy scavenging fittings and such to plumb it for recirc/whirlpool/cfc using a Mark II pump. The only thing I didn't have was a dip tube and as far as off-the-shelf solutions go, there isn't much that will fit between the inner wall and mash tube. Then I stumbled across the Spincycle whirlpool return from brewhardware.com. I reached out to Bobby to get the thickness of the part, to which he replied that it's 7/8" thick. My calipers read that the gap was .9". That's not much in the way of tolerance, but stormed ahead and took a chance on it with the intent on cutting off the down tube to the length I needed. The good news is that it fit cozily in the gap without any M&B modification:

So, can I get some opinions on whether I should be directing the dip tube to be drawing the uptake wort across the temperature sensor like I have in the pic, or should I point it the other way? I have enough length left on to tube to change the cut angle and rotate it away, but would it make any difference? I feel like the sensor would report more accurately to the controller if I'm drawing the recirculation across it, but now I'm second-guessing this approach.

Any thoughts on this?

So, can I get some opinions on whether I should be directing the dip tube to be drawing the uptake wort across the temperature sensor like I have in the pic, or should I point it the other way? I have enough length left on to tube to change the cut angle and rotate it away, but would it make any difference? I feel like the sensor would report more accurately to the controller if I'm drawing the recirculation across it, but now I'm second-guessing this approach.

Any thoughts on this?