You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Basement Brew Pub

- Thread starter rvklein

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

View of the bar. Note the beer money jar. I should have gotten a bigger one.

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

I still need to order a non-ghetto drip tray.

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

Liquor shelf & 3 zone wine/bottle coolers.

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

This is where the magic happens. Glycol in/out & the Trunkline runs into the keezer where they're coupled. Glycol constantly recirculates from the Keezer to the Tap 100' away.

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

Trunkline running into the ceiling out to the bar.

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

Kegs inside the Keezer. Couplers have built-in Foam detectors to shut off flow when the Keg's empty saving the 1/2 Gallon of beer in the line

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

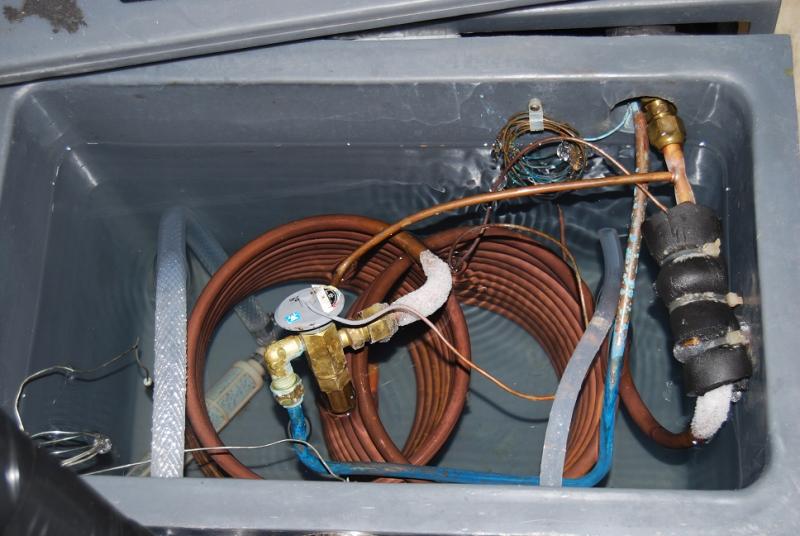

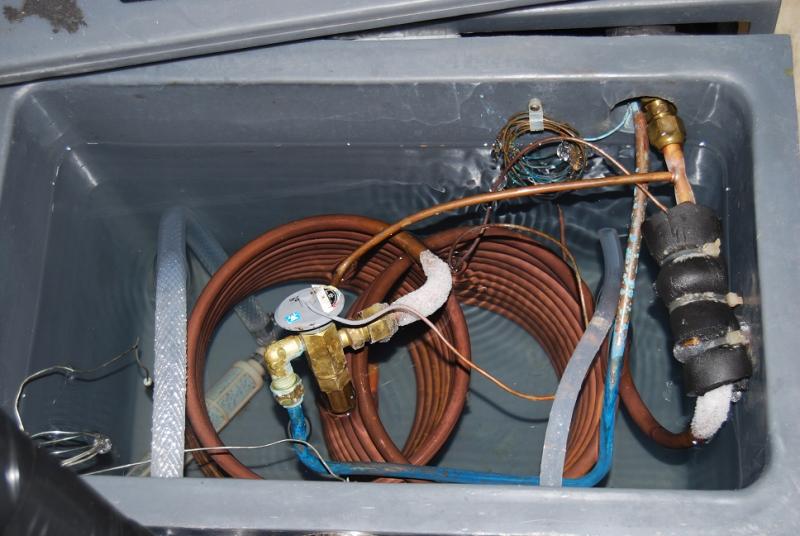

28 Degree Glycol Bath. Notice the ice forming on components exposed to air.

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

Homemade Long Draw line cleaning can. Fill with cleaning solution then hook up to the beer/gas lines and run like a normal keg then blow out the line with gas.

Only disadvantage over commerical cleaning cans is I have to clean the sankey coupler separately. The advanatage is I had most of the parts laying around and commerical cans are $400!

Only disadvantage over commerical cleaning cans is I have to clean the sankey coupler separately. The advanatage is I had most of the parts laying around and commerical cans are $400!

Hoppopotomus

Cedar Hollow Brewing

I've said it before and I'll say it again.....Simply Amazing!

Hoodweisen

Well-Known Member

I wonder how much beer is in 100 foot of beer line seem to me when a keg would be cashed there would still be several beers intransit

awesome build

awesome build

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

100' of 5/16" diameter line holds .5 gallon of beer. I use foam detectors (FOBs) at the kegs to shut down the line when the keg is spent. Tap another keg and no loss of beer.I wonder how much beer is in 100 foot of beer line seem to me when a keg would be cashed there would still be several beers intransit

kal

Well-Known Member

Some questions for you rvklein as I'm embarking on a similar project:

- Can you tell us more about the foam detectors? What make/model? What do they typically cost?

- How loud is the 3/4 hp glycol chiller? (I don't want to hear it from my home theater).

- It's obvious you really did your homework. That said, were there any other lessons learnt that weren't obvious until you got into building or using phase of this bar? Things that in retrospect would have made you change something earlier on?

Kal

- Can you tell us more about the foam detectors? What make/model? What do they typically cost?

- How loud is the 3/4 hp glycol chiller? (I don't want to hear it from my home theater).

- It's obvious you really did your homework. That said, were there any other lessons learnt that weren't obvious until you got into building or using phase of this bar? Things that in retrospect would have made you change something earlier on?

Kal

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

Typically nice (stainless steel) ones sell for $100-$120ea. However Perlick makes a 'smart' coupler with a built in FOB for around $65. They are the only maker of an integrated coupler/FOB. I was reluctant at first given the big cost difference had I purchased separte FOBs but considering it's a savings of $420 for the six lines I gave it a go. They do the job.Some questions for you rvklein as I'm embarking on a similar project:

- Can you tell us more about the foam detectors? What make/model? What do they typically cost?

http://www.perlick.com/pdf-files/Z2148.pdf

When the compressor is running (and it runs often), LOUD. Go with a smaller compressor if you don't need more than 150' of trunk line. 3/4 hp also requires a 20AMP circuit. If I can pick up a smaller unit cheap in the future I will.- How loud is the 3/4 hp glycol chiller? (I don't want to hear it from my home theater).

That said, I have it in a room directly adjacent to my Home Theater with no form of insulation on the wall and it's not too terrible with the door closed. I Imagine if I Dynamat the wall & door I really wouldn't notice it.

When planning out the remote draw system I was kicking myself for not having more direct draw capacity at the bar. But now that everything is up and running I'd say it was a fortuitous oversight. Large direct draw units are loud and produce alot of heat. Not something you want in an entertainment area.- It's obvious you really did your homework. That said, were there any other lessons learned that weren't obvious until you got into building or using phase of this bar? Things that in retrospect would have made you change something earlier on?

Kal

Right now I don't think I'd change a thing. (other than more taps which my wife quickly shot down)

kal

Well-Known Member

Thanks for the info!

And by loud and hot you mean the general noise and heat that a fridge produces? Why would it be any louder than (say) the two wine cooler/fridges you have in the bar now?

Assuming I'm understanding correctly, why did you originally think you wanted more direct draw capacity at the bar?

I had 4 before and will be aiming for 6-8 on the new setup.

I had 4 before and will be aiming for 6-8 on the new setup.

Kal

These look like Sanke couplers only right?. I could have sworn from previous pictures that you also served from corny kegs no?Typically nice (stainless steel) ones sell for $100-$120ea. However Perlick makes a 'smart' coupler with a built in FOB for around $65. They are the only maker of an integrated coupler/FOB. I was reluctant at first given the big cost difference had I purchased separte FOBs but considering it's a savings of $420 for the six lines I gave it a go. They do the job.

Good to know. If I need one at all it'll likely be a 1/3 HP unit.When the compressor is running (and it runs often), LOUD. Go with a smaller compressor if you don't need more than 150' of trunk line. 3/4 hp also requires a 20AMP circuit. If I can pick up a smaller unit cheap in the future I will.

Sorry, the terminology is new to me: What do you mean by 'direct draw' systems? You mean like a kegorator or table like this?:When planning out the remote draw system I was kicking myself for not having more direct draw capacity at the bar. But now that everything is up and running I'd say it was a fortuitous oversight. Large direct draw units are loud and produce alot of heat. Not something you want in an entertainment area.

And by loud and hot you mean the general noise and heat that a fridge produces? Why would it be any louder than (say) the two wine cooler/fridges you have in the bar now?

Assuming I'm understanding correctly, why did you originally think you wanted more direct draw capacity at the bar?

You can never have enough taps.Right now I don't think I'd change a thing. (other than more taps which my wife quickly shot down)

Kal

kal

Well-Known Member

One more question:

If the distance is too long like yours I understand that you need to push with beer gas (pre-blended C02 / Nitrogen) or pure Nitrogen. Reason being that the serving pressure has to be set high to push the long distance, and if it's C02 it may be set so high as to over-carb the beer over time.

You're blending it yourself you mentioned. Are you doing this because you want two different blends as you said (depending on style) or because it's cheaper to blend yourself than buy it pre-blended? Or both?

Kal

If the distance is too long like yours I understand that you need to push with beer gas (pre-blended C02 / Nitrogen) or pure Nitrogen. Reason being that the serving pressure has to be set high to push the long distance, and if it's C02 it may be set so high as to over-carb the beer over time.

You're blending it yourself you mentioned. Are you doing this because you want two different blends as you said (depending on style) or because it's cheaper to blend yourself than buy it pre-blended? Or both?

Kal

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

Ah, yeah sorry. For corny's you'll need sparate FOBsThese look like Sanke couplers only right?. I could have sworn from previous pictures that you also served from corny kegs no?

Yeah. Direct Draw meaning the tap & refrigeration are all-in-one vs Long Draw where they are separate.Sorry, the terminology is new to me: What do you mean by 'direct draw' systems? You mean like a kegorator or table like this?:

I'm not sure what size compressor the Kitchen Aid's use but commonly your commercial direct draw units start with 1/4 hp compressors vs 1/20-1/8hp for small refrigerators. A friend of mine has a large Beverage Air kegerator and it produces alot of heat/noise relative to my Kitchen Aid's which are virtually silent.And by loud and hot you mean the general noise and heat that a fridge produces? Why would it be any louder than (say) the two wine cooler/fridges you have in the bar now?

It could also be a consumer vs commercial issue where high end consumer appliances take pains to produce quiet products.

That's what I told her!!!You can never have enough taps.I had 4 before and will be aiming for 6-8 on the new setup.

Kal

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

Both. Preblended "Beer Gas" is typically a single blend more suited to stouts then Ales/Lagers which need a 60/40 CO2/NO blend to maintain proper carbonation levels. Unfortunately the only game in town for onsite blending is McDantim. Everyone else rebrands them. A dual blender will run you $1000 but if your patient you can score one on ebay for $300. They are purely mechanical so I wouldn't be too worried about buying a used one.One more question:

If the distance is too long like yours I understand that you need to push with beer gas (pre-blended C02 / Nitrogen) or pure Nitrogen. Reason being that the serving pressure has to be set high to push the long distance, and if it's C02 it may be set so high as to over-carb the beer over time.

You're blending it yourself you mentioned. Are you doing this because you want two different blends as you said (depending on style) or because it's cheaper to blend yourself than buy it pre-blended? Or both?

Kal

kal

Well-Known Member

So you don't use FOBs on your corny's? Why only on the Sanke's?Ah, yeah sorry. For corny's you'll need sparate FOBs

Gotcha. Make sense.A friend of mine has a large Beverage Air kegerator and it produces alot of heat/noise relative to my Kitchen Aid's which are virtually silent.

The trick is like a tap tower that only starts at 8 taps.That's what I told her!!!

They (unfortunately?) only starts at 8 taps and goes up from there. I have no choice but to go with 8 taps.

Did you ever consider an glass rinser? I'm considering at installing the tower on top of a drip tray with integrated glass rinser like this:

Kal

kal

Well-Known Member

Both. Preblended "Beer Gas" is typically a single blend more suited to stouts then Ales/Lagers which need a 60/40 CO2/NO blend to maintain proper carbonation levels. Unfortunately the only game in town for onsite blending is McDantim. Everyone else rebrands them. A dual blender will run you $1000 but if your patient you can score one on ebay for $300. They are purely mechanical so I wouldn't be too worried about buying a used one.

So 60/40 is the standard C02/N2 ratio? As high as 60% C02 there's no issue with overcarb'ing the beer even with your 100 foot lines? 60% seems high. I wonder at what point it would start being an issue for you with your 5/16" ID lines.

Kal

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

I only use sanke's. Once I finish the brewery I plan on kegging in sanke's too. We'll see how that goes.So you don't use FOBs on your corny's? Why only on the Sanke's?

Now see, there is a smart manThe trick is like a tap tower that only starts at 8 taps.These the sorts of styles that I like:

Oh geez, there you go getting me thinking....I'm already blaming you for the electric brewery...Did you ever consider an glass rinser? I'm considering at installing the tower on top of a drip tray with integrated glass rinser like this:

No problems running between 20-25 psi. I have one IPA which gets 'flat' @ 20 psi. I run the stout @ 35+ psiAs high as 60% C02 there's no issue with overcarb'ing the beer even with your 100 foot lines? 60% seems high. I wonder at what point it would start being an issue for you with your 5/16" ID lines.

kal

Well-Known Member

My work here is done...Oh geez, there you go getting me thinking....I'm already blaming you for the electric brewery...

I first considered it when I saw that for the 8-tap tower I was considering, the drip tray with integrated glass rinser was (for some reason) only $4 more than the other model without a glass rinser.

Often when people come over they want to try out all the different types of beers I have so I end up quickly rinsing their glass in-between in the sink anyway. I thought it would be cool to be able to do it with an 'real' glass rinser. I wasn't even considering the other advantages which they list as:

- Rinse away any impurities that might be in the glass.

- Chill the glass utilizing cold water.

- A wetted glass pours better.

I don't know if bars always do this however. Probably not. At least probably not during high volume times. Probably depends on the bartender too.

Some of the installation info however has me wondering how many hidden costs are in here and/or if it's really worth it. They say:

- Install in-line water regulator set at 15 PSI from the street water supply (no greater, perfect operating pressure). (I think most houses have higher pressure. No idea what an in-line water regulator costs! Note that the product litterature says 30 PSI, not 15 PSI. Not sure which is right or if it really matters. - Kal)

- Install in-line one way check valve from the street water supply (prevents pressure drop which can cause leaking). (I take it that if the pressure gets too low the thing might turn into a water fountain as the pressure wouldn't be enoug to hold it closed correctly. Last thing you want is to come downstairs one day to a giant puddle on the floor - Kal)

- Install in-line shut-off for the rinser system from the street water supply (this must be turned off nightly). (The 'turned off nightly' has me worried... is that because these things are prone to leaking? They should only be on when someone's around? If I have to turn it on/off every time I go to use it it's not exactly more handy than having a sink! - Kal)

Kal

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

While I'm truly envious of your bar, I think I'd trade jobs and wife with you...the rest would come easier after that swap. My job doesn't pay enough and my wife would NEVER go for a bar in the basement, no matter how nice it was.

Beautiful setup for sure!

Beautiful setup for sure!

I'm looking to put my kegerator in my shed then run a beer line to the house its about 8mtres away would the co2 be enough to get the beer that far?

And would the beer left in beer line go bad while its waiting for me 2 drink it?

And would the beer left in beer line go bad while its waiting for me 2 drink it?

kal

Well-Known Member

8 meters is 26 feet. Use larger 1/4" or 5/16" tubing (preferrably PVC barrier tubing that doesn't restrict flow as much) and you'll be able to push with C02 and likely not overcarb it.

The beer won't go bad as long as the system sealed (no air getting in or beer getting out). If it doesn't leak, it's sealed.

If you don't chill the 26 feet however, you'll get a bunch of foam every time you go to pour unless you just happened to pour one just a few minutes before. This is what glycol chilling or air chilling is for. 26 feet is probably low enough that you could air chill or glycol chill using a pond pump to circulate. My last bar had 12-16 foot 1/4" barrier tubing PVC lines that I chilled effectively with a (reasonably small) pond pump with glycol that was recirculated through a copper coil placed in the freezer of the bar fridge.

Kal

The beer won't go bad as long as the system sealed (no air getting in or beer getting out). If it doesn't leak, it's sealed.

If you don't chill the 26 feet however, you'll get a bunch of foam every time you go to pour unless you just happened to pour one just a few minutes before. This is what glycol chilling or air chilling is for. 26 feet is probably low enough that you could air chill or glycol chill using a pond pump to circulate. My last bar had 12-16 foot 1/4" barrier tubing PVC lines that I chilled effectively with a (reasonably small) pond pump with glycol that was recirculated through a copper coil placed in the freezer of the bar fridge.

Kal

Flight boarding. Ran out of time at page 13 but I had to subscribe so I can get back to this later.

Amazing

Amazing

Pretty nice layout. The bar is a beauty! We have a theater in our basement also (26ft x 16ft) with two tiers of curved reclining HT seats (4 seats per tier). A 110" 16:9 screen and projector. I have two cylinder subs that I built with 2000 WPC each and then the rest of the audio gear. My original plan was to add a wine bar in the back of the theater, but that just never happened. The subs would probably shake most of the glassware off the wine shelves anyway. In February, I'm going to take out a wall in the adjoining room to make it larger and we are thinking about adding a small bar...nothing like yours though. I'd love to have a couple of taps and my wine bar though.

NewBrewB said:Flight boarding. Ran out of time at page 13 but I had to subscribe so I can get back to this later.

Amazing

I don't know how I missed this thread in the past but it is pretty crazy. I appreciated the garage/car pic though because it reminded me that this thread is for looking not touching.

My redesigned wet bar seems so elementary compared to the scale of this basement build.

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

Pretty nice layout. The bar is a beauty! We have a theater in our basement also (26ft x 16ft) with two tiers of curved reclining HT seats (4 seats per tier). A 110" 16:9 screen and projector. I have two cylinder subs that I built with 2000 WPC each and then the rest of the audio gear. My original plan was to add a wine bar in the back of the theater, but that just never happened. The subs would probably shake most of the glassware off the wine shelves anyway. In February, I'm going to take out a wall in the adjoining room to make it larger and we are thinking about adding a small bar...nothing like yours though. I'd love to have a couple of taps and my wine bar though.

I wish I could have built a larger theater room however it's size was dictated by the location of my HVAC which is inches from the right hand wall. I suppose I could have sacrifice bar space but that's just crazy talk...

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

OMG it took me forever. Now talking to John @ Stout Tanks and Kettles about getting the tanks & fermenter. It annoys me that the AMP meter reads 5 AMPs though

A big Thank You goes to Kal for his site.

A big Thank You goes to Kal for his site.

upperNY01brewer

Well-Known Member

Holy schmidt that is freaking amazing !!!!!!!!!!

kal

Well-Known Member

Nice! All you need are the panel tags to make it complete! (and maybe fix that ampmeter issue if it bugs you...)

Kal

Kal

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

Got'em ordered. To update you're site, the tags are $1.50 now. But I don't think it'll break the bank...

kal

Well-Known Member

Thanks for the heads up! I removed all mention of tag pricing from the site to avoid any confusion.

Kal

Kal

- Joined

- Dec 9, 2008

- Messages

- 555

- Reaction score

- 51

Tri clamp element adapter. Just a minor tweak to Kal's. The ripple element will touch the inside of the tank's ferrule but I don't think that's too big a deal.

Similar threads

- Replies

- 6

- Views

- 3K

- Replies

- 20

- Views

- 3K

- Replies

- 32

- Views

- 3K

- Replies

- 0

- Views

- 629