You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another 1 bbl brewer

- Thread starter MikeRLynch

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

MikeRLynch

Well-Known Member

Ok, not a lot of work on the brewery itself, but we did find ourselves with an extra tank and some valves and fittings....so we decided to build ourselves a smoker

This is in the style of the "ugly drum smokers" some of you might have seen out there. Started with one of the tanks that has a ball valve in the bottom

Installed an elbow and a pipe to the ball valve, this is where we'll regulate the flow of air to the fire.

Installing a butterfly valve on the top of the pipe. We'll leave the valve on the tank open all the way, and adjust the airflow with this valve. Why didn't we just use the ball valve on the tank? Cause we have a buttload of parts and we're lazy and don't want to bend over

This is in the style of the "ugly drum smokers" some of you might have seen out there. Started with one of the tanks that has a ball valve in the bottom

Installed an elbow and a pipe to the ball valve, this is where we'll regulate the flow of air to the fire.

Installing a butterfly valve on the top of the pipe. We'll leave the valve on the tank open all the way, and adjust the airflow with this valve. Why didn't we just use the ball valve on the tank? Cause we have a buttload of parts and we're lazy and don't want to bend over

MikeRLynch

Well-Known Member

The lid, just so happens our 2" triclovers screw in perfectly to the hole on 55gal drum lids! The exaust assembly, another butterfly valve to dial in the flow of smoke. The angled pipe can be rotated to keep it out of the wind

A little lid modification

Some bolts to hold the grill

Finished product! We're using a little Weber smokey joe grill inside to hold the coals and smoking wood

A little lid modification

Some bolts to hold the grill

Finished product! We're using a little Weber smokey joe grill inside to hold the coals and smoking wood

That is a cool smker. Nice controls, made anything yet?

bendavanza

Well-Known Member

That has to be the most expensive (if you had to buy new parts) smoker I've ever seen. Since you've gone this far, how about cutting a door in the side to access your coals and wood?

Stay focused guys. We cant afford to have you off building all-a-kinda stuff and not finish up the brewery. That was a great fermentation vessel that you just drilled holes in to put the grill on. Smoked sausage would be good with a beer now that I think of it

Looks like your having fun keep us posted.

Looks like your having fun keep us posted.

klyph

Well-Known Member

That was a great fermentation vessel that you just drilled holes in to put the grill on.

I was gonna say, do you guys even have fermentation capacity for 1 bbl? Hacking up a $$$ vessel like that seems like a rash decision.

MikeRLynch

Well-Known Member

I was gonna say, do you guys even have fermentation capacity for 1 bbl? Hacking up a $$$ vessel like that seems like a rash decision.

Lol, thanks for all the concern guys, but we didn't waste good steel :cross: The tank you see was damaged in shipping, and the top section was bent out of round and there's a crack in the steel on the lip. The lid does not seal all around it, in fact, on one side there is a good 3/4" gap. We're working on ways to gasket the smoker lid down so the gap is sealed and smoke doesn't escape. But as for using it as a fermenter, because of the defect, we were not going to use it anyway.

As for cost, that tank was less than $100 bucks, and all the fittings were free. We're serious about bbq, so it's money well spent. Besides, we bbq when we brew anyway, and now our smoker will match our brewery

As for fermentation capability, we have another identical 60 gal tank, undamaged. We also have another jacketed tank on the way, but more on that later

ahave

Well-Known Member

Looks like fun!

Dare I ask where you are getting such sweet equipment? and for so cheap?

Dare I ask where you are getting such sweet equipment? and for so cheap?

klyph

Well-Known Member

I guess now you won't even need to butcher the pig before smoking it, just toss the whole thing in and fire it up :rockin:

MikeRLynch

Well-Known Member

I guess now you won't even need to butcher the pig before smoking it, just toss the whole thing in and fire it up :rockin:

It's been discussed, but we concluded the legs might stick out. While hilarious, not the best conditions for smoking :fro:

As for the gear, we're getting it from a plant that closed. A buddy of ours works there, and rather than the company paying to dispose of the leftovers, we graciously offered to alleviate them of their excess steel

Cpt_Kirks

Well-Known Member

It's been discussed, but we concluded the legs might stick out. While hilarious, not the best conditions for smoking :fro:

You just need a bigger smoker:

:rockin:

MikeRLynch

Well-Known Member

With the weather getting nicer, we're starting to get balls rolling

The first 'staff meeting' is tonight, and hopefully some hard dates will be established for getting things done. I might be jinxing us here, but I'd like to get the first batch out by October.

We haven't been entirely idle, in fact we've gotten about a dozen brews done recently, and I'm glad to report that the stock water from the well makes some damn tasty beer. English styles seem to do very well with it, we made an outstanding oatmeal stout and an ESB bumped up with a little orange blossom honey. Still working on the hoppy styles, it may take some chemistry to get those to work. Stay tuned, pics as they become available!

The first 'staff meeting' is tonight, and hopefully some hard dates will be established for getting things done. I might be jinxing us here, but I'd like to get the first batch out by October.

We haven't been entirely idle, in fact we've gotten about a dozen brews done recently, and I'm glad to report that the stock water from the well makes some damn tasty beer. English styles seem to do very well with it, we made an outstanding oatmeal stout and an ESB bumped up with a little orange blossom honey. Still working on the hoppy styles, it may take some chemistry to get those to work. Stay tuned, pics as they become available!

magarnigel

Active Member

Subscribed. I will be having some wonderful dreams tonight now.

TheWhaleShark

Well-Known Member

This thread is of great interest to me, since I'm planning on building a 1 bbl system in the next couple of years. I've been looking at tanks very similar to the ones you've got there, so it's good to know other people are trying the "Frankenstein" approach too.

One question: what are you going to use for the heat source for the BK? You think those tanks can take direct fire? I've been researching the possibility of using submersible heating elements and going all electric, but I'm not really sure at what volume that stops being feasible. Anyone have any thoughts?

One question: what are you going to use for the heat source for the BK? You think those tanks can take direct fire? I've been researching the possibility of using submersible heating elements and going all electric, but I'm not really sure at what volume that stops being feasible. Anyone have any thoughts?

RegionalChaos

Well-Known Member

I've been researching the possibility of using submersible heating elements and going all electric, but I'm not really sure at what volume that stops being feasible. Anyone have any thoughts?

There is a formula you can use to determine how many BTU you need to raise a specific volume of water a specific number of degrees. You can use this formula along with the BTU - Kw rating of the heating elements to determine how much Kw you would need to raise a specific volume a specific amount. Someone might chime in with the formula. I know The Pol has talked about having it laid out in a spread sheet so he can just pop in the variables. I started to lay it out, but haven't finished it.

TheWhaleShark

Well-Known Member

Oh, that would make sense. One BTU is approximately the amount of energy needed to raise one pound of water by one degree Farenheit.

MikeRLynch

Well-Known Member

I would love to see this formula, it would certainly be helpful.

Right now we are planning on heating with electric immersion elements, like the ones you see on many of the e-rigs here. I believe Squam Lakes on the forums here does full 1 barrel batches with only electric heat. However, when attempting something this big, it will require a lot of juice. If you don't absolutely know what you're doing, go direct fire. My brewing partner is an electrician and owns his own company, so he's experienced and safe.

The reason for going electric mainly is due to the ball valves being located on the bottom of each kettle. I dont think they would stand up to being heated directly with flames.

Right now we are planning on heating with electric immersion elements, like the ones you see on many of the e-rigs here. I believe Squam Lakes on the forums here does full 1 barrel batches with only electric heat. However, when attempting something this big, it will require a lot of juice. If you don't absolutely know what you're doing, go direct fire. My brewing partner is an electrician and owns his own company, so he's experienced and safe.

The reason for going electric mainly is due to the ball valves being located on the bottom of each kettle. I dont think they would stand up to being heated directly with flames.

TheWhaleShark

Well-Known Member

I've got some electrician friends. I believe their help can be secured in exchange for delicious beer.I would love to see this formula, it would certainly be helpful.

Right now we are planning on heating with electric immersion elements, like the ones you see on many of the e-rigs here. I believe Squam Lakes on the forums here does full 1 barrel batches with only electric heat. However, when attempting something this big, it will require a lot of juice. If you don't absolutely know what you're doing, go direct fire. My brewing partner is an electrician and owns his own company, so he's experienced and safe.

The reason for going electric mainly is due to the ball valves being located on the bottom of each kettle. I dont think they would stand up to being heated directly with flames.

But yes, I was thinking much the same thing; I'm unsure as to the ability of tanks like those and the drain fittings to stand up to direct fire. Also, I'm pretty sure local zoning boards would probably rather see electric elements than an indoor fire, and if I can make the whole brewhouse electric, I'm thinking of installing solar panels to defray the costs and get some fat tax credits.

Of course, this is all still in the extremely preliminary phase.

thewhaleshark:

I have a one barrel, all electric system. I have two 4500 watt elements in both my HLT and BK. It is a little undersized from a power standpoint. To start my day, I heat 50 gallons of water to 170F in my BK and then pump into MT and HLT. I can raise 50 gallons of water by slightly more than 1 degree F per minute. I run my BK on 85% power after the wort is brought to a boil. The time it takes the wort to get up to a boil does not seem so bad as you can start heating during the sparge as soon as the BK elements are covered with wort. I think two 5500 watt elements would be better but then you will need a 60 amp GFI breaker.

I have a one barrel, all electric system. I have two 4500 watt elements in both my HLT and BK. It is a little undersized from a power standpoint. To start my day, I heat 50 gallons of water to 170F in my BK and then pump into MT and HLT. I can raise 50 gallons of water by slightly more than 1 degree F per minute. I run my BK on 85% power after the wort is brought to a boil. The time it takes the wort to get up to a boil does not seem so bad as you can start heating during the sparge as soon as the BK elements are covered with wort. I think two 5500 watt elements would be better but then you will need a 60 amp GFI breaker.

Here is a calculator:

http://www.brewheads.com/calc.php

http://www.brewheads.com/calc.php

Whale Shark

At Squam Brewery we used two 5000 watt elements and it does a great job for a 1bb system. There are lots of good reasons to use electric. Two nice benefits of electric is that you save money as its much cheaper to brew with electric. The other one is that when you reach the boil rate you like, you can just let it run. You don't have to keep watching it, you don't have to fret about a boil over. We used Brewmation http://www.brewmation.com to build the conversion system and it was well worth the few extra bucks to have an expert design it.

At Squam Brewery we used two 5000 watt elements and it does a great job for a 1bb system. There are lots of good reasons to use electric. Two nice benefits of electric is that you save money as its much cheaper to brew with electric. The other one is that when you reach the boil rate you like, you can just let it run. You don't have to keep watching it, you don't have to fret about a boil over. We used Brewmation http://www.brewmation.com to build the conversion system and it was well worth the few extra bucks to have an expert design it.

TheWhaleShark

Well-Known Member

Wow, there really are a lot more nanobrewers out there than I thought!

One thing I've been thinking about is researching - in addition to the solar panels - a point-of-use hot water heater with a commercial controller, to output hot water up to 185 F. That would eliminate the need for a HLT, taking an entire tank and pump assembly out of the equation (or at least changing it around) and possibly shortening the brew day. Plus, the POU hot water heaters can qualify for efficiency credits.

We have a lot of machine shops and the like here in New York's capital district, so I'm sure I can find a place that has sufficient electrical. Hell, I just found a guy on Craigslist renting his garage/machine shop for cheap.

If you wanted to scale up eventually - say 3 bbl electric - you'd probably need something more like 3 7kw heaters in the kettle, assuming you're starting with some pretty hot wort (which you should have following the sparge) and the aforementioned POU water heater.

Anyhow, those are just the thoughts I've been bouncing around.

One thing I've been thinking about is researching - in addition to the solar panels - a point-of-use hot water heater with a commercial controller, to output hot water up to 185 F. That would eliminate the need for a HLT, taking an entire tank and pump assembly out of the equation (or at least changing it around) and possibly shortening the brew day. Plus, the POU hot water heaters can qualify for efficiency credits.

We have a lot of machine shops and the like here in New York's capital district, so I'm sure I can find a place that has sufficient electrical. Hell, I just found a guy on Craigslist renting his garage/machine shop for cheap.

If you wanted to scale up eventually - say 3 bbl electric - you'd probably need something more like 3 7kw heaters in the kettle, assuming you're starting with some pretty hot wort (which you should have following the sparge) and the aforementioned POU water heater.

Anyhow, those are just the thoughts I've been bouncing around.

RegionalChaos

Well-Known Member

Yea, I have an instant hot water heater on my upgrade map at the 1 bbl level. I think it makes so much sense. There is someone here, I forget who, that has one mounted on a cart for their brewery system.

MikeRLynch

Well-Known Member

I've been looking at the POU water heaters as well, not sure if they would work efficiently on the scale we're talking about. After all, it's just passing water over a bunch of immersion elements anyway, can't we just do that in an electric hlt? Essentially, we're just making a big household hot water heater.

TheWhaleShark

Well-Known Member

I dunno, many of the commercial ones I've looked at advertise up to 2.something GPM at very high temperatures, though those are all natural gas. The electric ones operate a little slower and don't give as much rise, though I wonder if you could connect two in a series. Like, the first one would be a pre-heater and the second one would give you your final output temperature.I've been looking at the POU water heaters as well, not sure if they would work efficiently on the scale we're talking about. After all, it's just passing water over a bunch of immersion elements anyway, can't we just do that in an electric hlt? Essentially, we're just making a big household hot water heater.

I think the big difference is that it's easier to heat up a small volume of water using less energy. It's also similar to the principle of a counterflow chiller. You're constantly moving non-heated water over very hot coils. In a conventional setup, you're relying on the hotter water to transfer heat to the cooler water, which is a slow process.

Keep it simple

10,000 watts in your Brew Kettle is all you need. pump to your HLT, sparge and pump to your brew kettle. with 40-50 gallons of mass the sparge water hardly drops at all.

10,000 watts in your Brew Kettle is all you need. pump to your HLT, sparge and pump to your brew kettle. with 40-50 gallons of mass the sparge water hardly drops at all.

BoarBeer makes a great point. With the large thermal mass of the mash and sparge water, temps drop very little over the time course of a typical mash. I am still using a HERMS but I am about to abandon it because it is difficult to get enough flow to really control the temp of a large mash (60-90 lbs of grain). My HERMS worked great on 15 gallon batches but is basically worthless on 30 gallon batches.

RegionalChaos

Well-Known Member

Steve, is that because the thermal mass of a large mash is not easily adjusted with the small volume being pumped through the HERMS?

I've thought about a HERMS setup for 10-15g batches, so I'm curious..

I've thought about a HERMS setup for 10-15g batches, so I'm curious..

Yes, temp control with a HERMS or RIMS is largely a function of flow thru the system and thermal mass of the mash. This is, of course, assuming you have an adequate heat source to raise the temp of the wort flowing thru the heat exchanger. For example, if you have good temp control with flow of X and thermal mass of Y and then you change your thermal mass to 2Y, your ability to control the temperature of the mass will be greatly diminished. The flow thru my system is limited largely by the resistance of the HERMS coil and sometimes by grain bed compaction. Like I said earlier, I had great control with 15 gallon batches and could easily mash out from 150 to 165F in 15 minutes. When I went to 30 gallon batches, I could maintain mash temps but could not raise my mash temp fast enough to mash out in less than 30 minutes. During "mash out", the temp of wort returning to the mash tun is 170F but there is not enough flow to raise the temp of the mash in a reasonable amount of time.

RegionalChaos

Well-Known Member

But is the need for adjustment diminished since the large thermal mass would help the tun maintain temp?

TheWhaleShark

Well-Known Member

@BoarBeer: Yeah, but then I don't get a neato burrito unidirectional flow! My scientist brain really likes that!

You're right, though; in the end, it's probably most economical to just have a single heating device, rather than multiple different heating devices for different purposes.

Lots of good advice in this thread. Definitely a good read. I'll be keeping close tabs on this.

You're right, though; in the end, it's probably most economical to just have a single heating device, rather than multiple different heating devices for different purposes.

Lots of good advice in this thread. Definitely a good read. I'll be keeping close tabs on this.

Kauai_Kahuna

Well-Known Member

Jonesing for more pictures here! But it just may be me.

Scottatron

Active Member

Jonesing for more pictures here! But it just may be me.

Same here. Any current pictures of the set up?

MikeRLynch

Well-Known Member

Alright, sorry for the lack of updates people, but that's because there's been a lack of work being done on the system. That is not, seemingly, a bad thing...

We've decided that it makes more sense from a business perspective to brew at the 7 bbl level. We do not, however have enough money or a place to put a 7 bbl system. We do however, have a semi local brewpub that may be willing to rent out their system and some fermentor space to us.

We would be getting an Alternating Proprietorship Brewing License. This will allow us to essentially piggyback on the existing breweries already established (and up to code) system/insurance/bonding/etc. With this we will be able to skip the problems of building a brewery and get right to making beer.

I know this thread is veering away from the DIY topic, but I figured I'd give a heads up. I'm not sure if I'll start another thread or post it on my blog, right now I'm up to my eyeballs in TTB forms and research. We will still be working on the 1 bbl system as time allows. We want to see it up and running as much as you do!

We've decided that it makes more sense from a business perspective to brew at the 7 bbl level. We do not, however have enough money or a place to put a 7 bbl system. We do however, have a semi local brewpub that may be willing to rent out their system and some fermentor space to us.

We would be getting an Alternating Proprietorship Brewing License. This will allow us to essentially piggyback on the existing breweries already established (and up to code) system/insurance/bonding/etc. With this we will be able to skip the problems of building a brewery and get right to making beer.

I know this thread is veering away from the DIY topic, but I figured I'd give a heads up. I'm not sure if I'll start another thread or post it on my blog, right now I'm up to my eyeballs in TTB forms and research. We will still be working on the 1 bbl system as time allows. We want to see it up and running as much as you do!

oldschool

Well-Known Member

Keep in mind that HOTD brews with a 4 bbl system.

MikeRLynch

Well-Known Member

Well, I figured I’d bring this thread back from the dead and give an update on what’s been going on in the past few years (can hardly believe it’s been that long since we first started this venture).

Life tends to get in the way, and progress on the brewery moved slowly. We spent a lot of time in the planning stage, trying to determine exactly what the best plan would be for us. We did our research, reading the TTB regs at lunch and doing market research at dinner. While we were getting our strategy together, the law changed in Connecticut. Breweries can now serve beer in their tasting rooms, where before they could only give free tastings (along with a mandatory tour). So now we can serve pints of our beer directly to the consumer right over our own bar. It was a huge game changer, and it made our idea of a little 1.5 bbl nano brewery feasible from a profit standpoint.

So armed with this new law we set to work opening the brewery in Woodstock, CT. Unfortunately Woodstock isn’t used to having any kind of real manufacturing businesses, and when we went to the town for the required permitting, they essentially stopped us in our tracks. We could do it, but we’d need special permitting. The first step was a survey and map of the building and grounds by an engineer, somewhere to the tune of $12,000. And that was before we put one shovel in the ground.

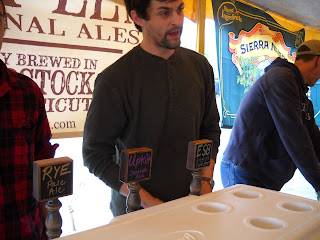

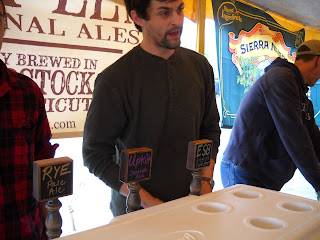

Needless to say, we couldn’t stay there. To say we’re doing this on a shoestring is generous, and we just couldn’t afford that much money. Luckily, the neighboring town of Stafford has been extremely helpful and welcoming, so we now rent a space near the center of town and are starting the demo on the new home of Lost Elm Brewing Company this week.

The new space is bigger, closer to the highway, has a bathroom, water plumbed in, floor drains, and a separate room big enough for our fermentation room and cold storage. The landlord has been very helpful and will most likely be helping us put together our brewhouse. It’s been a long time coming, but the ball is really rolling for us. Hopefully we can get all our paperwork in soon and get brewing within a few months.

We’ve used the resources here on homebrewtalk countless times, and we’re still coming on these boards to look up answers to questions or get ideas. If anyone has questions as they’re starting their own venture, feel free to ask us, we’ve probably gone through a lot of the same stuff. Look for more posts on the build, and the brewhouse construction in the coming days and weeks. Thanks to everyone on HBT!

Life tends to get in the way, and progress on the brewery moved slowly. We spent a lot of time in the planning stage, trying to determine exactly what the best plan would be for us. We did our research, reading the TTB regs at lunch and doing market research at dinner. While we were getting our strategy together, the law changed in Connecticut. Breweries can now serve beer in their tasting rooms, where before they could only give free tastings (along with a mandatory tour). So now we can serve pints of our beer directly to the consumer right over our own bar. It was a huge game changer, and it made our idea of a little 1.5 bbl nano brewery feasible from a profit standpoint.

So armed with this new law we set to work opening the brewery in Woodstock, CT. Unfortunately Woodstock isn’t used to having any kind of real manufacturing businesses, and when we went to the town for the required permitting, they essentially stopped us in our tracks. We could do it, but we’d need special permitting. The first step was a survey and map of the building and grounds by an engineer, somewhere to the tune of $12,000. And that was before we put one shovel in the ground.

Needless to say, we couldn’t stay there. To say we’re doing this on a shoestring is generous, and we just couldn’t afford that much money. Luckily, the neighboring town of Stafford has been extremely helpful and welcoming, so we now rent a space near the center of town and are starting the demo on the new home of Lost Elm Brewing Company this week.

The new space is bigger, closer to the highway, has a bathroom, water plumbed in, floor drains, and a separate room big enough for our fermentation room and cold storage. The landlord has been very helpful and will most likely be helping us put together our brewhouse. It’s been a long time coming, but the ball is really rolling for us. Hopefully we can get all our paperwork in soon and get brewing within a few months.

We’ve used the resources here on homebrewtalk countless times, and we’re still coming on these boards to look up answers to questions or get ideas. If anyone has questions as they’re starting their own venture, feel free to ask us, we’ve probably gone through a lot of the same stuff. Look for more posts on the build, and the brewhouse construction in the coming days and weeks. Thanks to everyone on HBT!

An excellent update! Though sorry about Woodstock not working out.

Similar threads

- Replies

- 0

- Views

- 614

- Replies

- 3

- Views

- 1K

- Replies

- 15

- Views

- 1K

- Replies

- 4

- Views

- 845