Just thought I would chime in here, I am also in the process of creating a 55 gal system.

One big difference in what I am doing from what I have seen here is my mashtun. My stainless 55 gal drum is laid sideways vs upright as most I have seen are doing. Sideways made a few design elements easier, and the mashbed is not as thick as an upright drum.

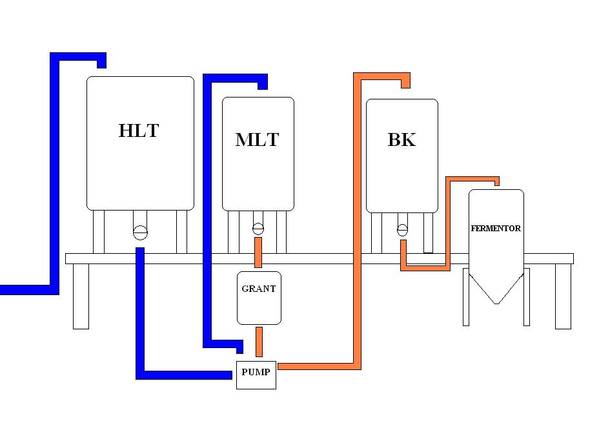

I have a pump mounted directly to the manifold/ss perf false bottom which will recirculate through the mashtun or pass to the boilkettle. This allows a controlled sparge rate. I am considering a rims addition using a commercial dishwasher inline hot water heater rated at 9 kw, being 3kw per element at 220, running at 120 to reduce power, and separate power switching for each of the 3 elements.

As I have read here, everyone loves beerporn, and as I get a bit further along I will post some.

The most difficult part for me has been the boilkettle. I do not want open air burners, they will be enclosed and vented/ducted using the standard impinged jet burners, I have a 200k btu and 300k btu. I found one need for the burner I was not aware of. When using them enclosed, you will need a baffle panel under the burner to pass the circulating air through the burner diameter as to make sure the air passes through the jets for best efficiency. Air bypassing the burner is not desired. I have not seen any systems (as of yet ) that use this feature. I am completing the burner and will be able to test and prove this concept soon. I am trying to reduce CO output for the sake of efficiency and cleanliness, as well as safety.

Thanks to you all for your great ideas here, I just had to make a few comments that I hadnt seen mentioned yet, and as always, time and brewing will prove me right or wrong, well not completely wrong, but less than optimal.

ImaBrewinfool