thejuanald

Well-Known Member

Edit: Oops I meant HERMS, not RIMS. Is there any way to edit the title?

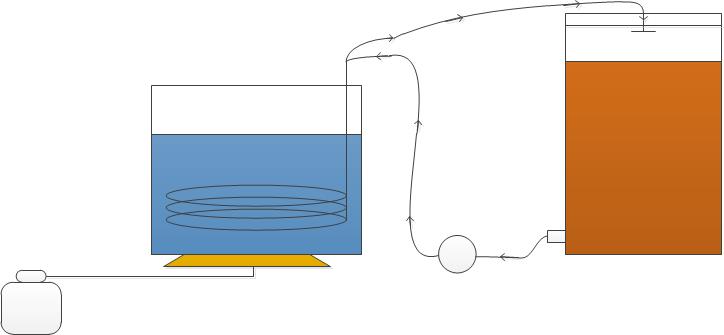

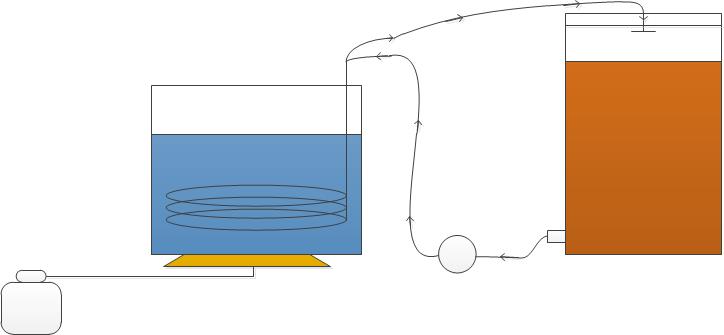

So I got a pump and a plate chiller for christmas and I wanted to try keeping my immersion chiller to use for a HERMS type system.

I only have one kettle, I use a propane burner, and I have a large cooler for the mash tun. If I do what's in the image, I could recirculate my mash and maintain temperature while maintaining temperature and then mash out by raising the temperature and then fly sparge with the water in the kettle. Does that seem reasonable or would it not work well because I'm using a propane burner and would have to watch the temps myself rather than if I went electric?

So I got a pump and a plate chiller for christmas and I wanted to try keeping my immersion chiller to use for a HERMS type system.

I only have one kettle, I use a propane burner, and I have a large cooler for the mash tun. If I do what's in the image, I could recirculate my mash and maintain temperature while maintaining temperature and then mash out by raising the temperature and then fly sparge with the water in the kettle. Does that seem reasonable or would it not work well because I'm using a propane burner and would have to watch the temps myself rather than if I went electric?