I'm curious, how do you plan to use it for bread proofing?

This is something I've already done (for the first proof, anyway). First proof happens in a large bowl in my usual bread process. All I had to do is set the bowl in the BK with the water level low enough that the bowl doesn't float.

Worked great! I did a side-by side dual batch and had one batch proof at room temp (70F in my case), and one in the proofing "chamber" at 80F. Noticeably faster/larger rise in the 80F one.

Second/third proof (post-shaping) could be done just by keeping the bread sheet above the water level by setting it on top of a pot or similar. The ambient temperature in the chamber basically matches the water temperature (tested alongside the above proofing test, as my BK thermometer is a bit high and in the air when the water levels are lower). Steam in the chamber could be beneficial or harmful depending on the bread, so definitely might have to figure out how to manage humidity in the chamber.

Re: Flow switches: Thanks all for the help with this! I'll probably make the flow switch a (small) task for the future as I fine-tune the system a bit.

Re: everything else: Got a whole lot of experimenting to do now that the build is working.

Experiment #1: Tonight! Sous vide steak. For science, doing a boneless ribeye and a NY strip side-by-side, 1.5 hours, 130F precisely for rarer side of medium rare.

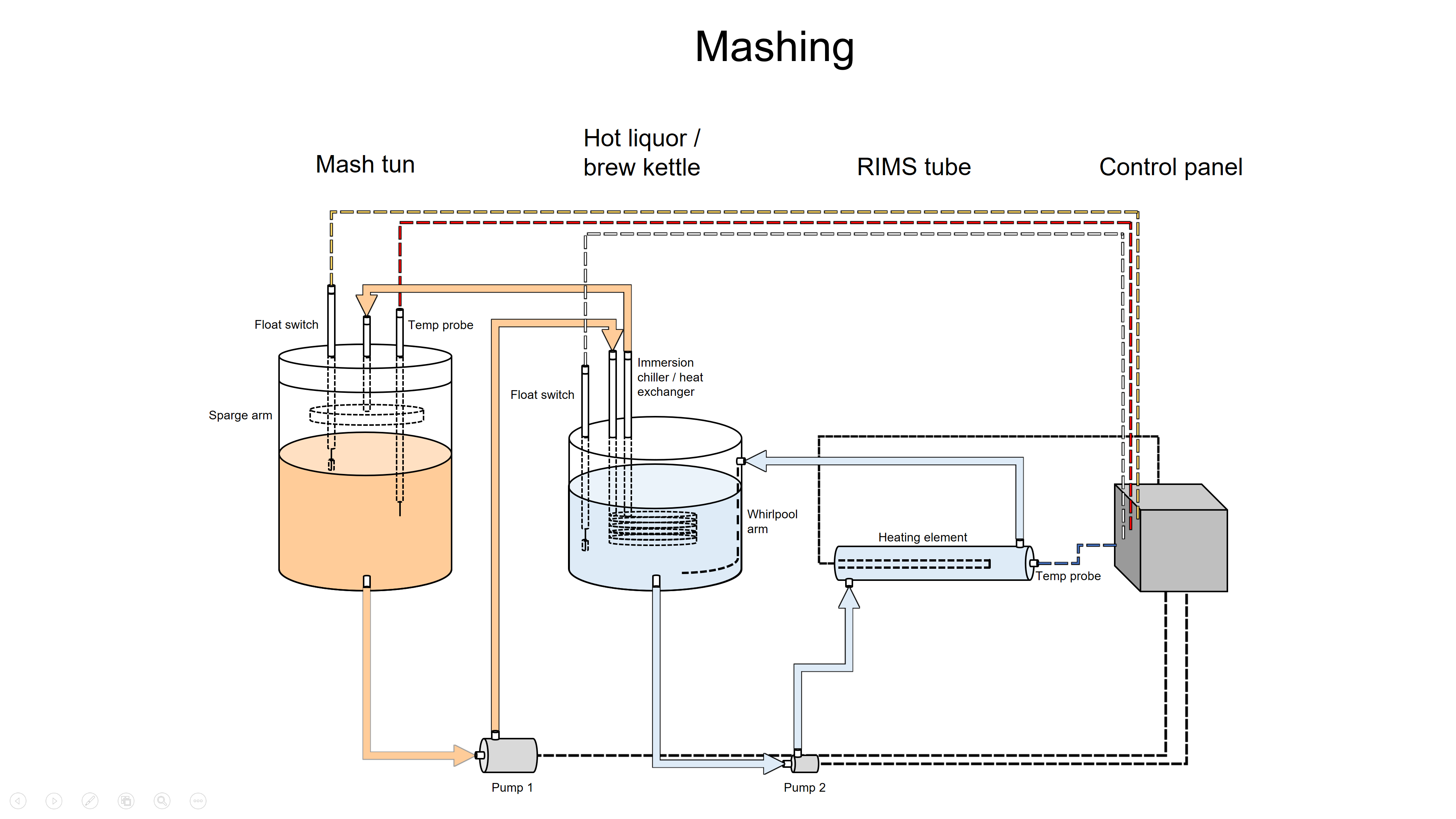

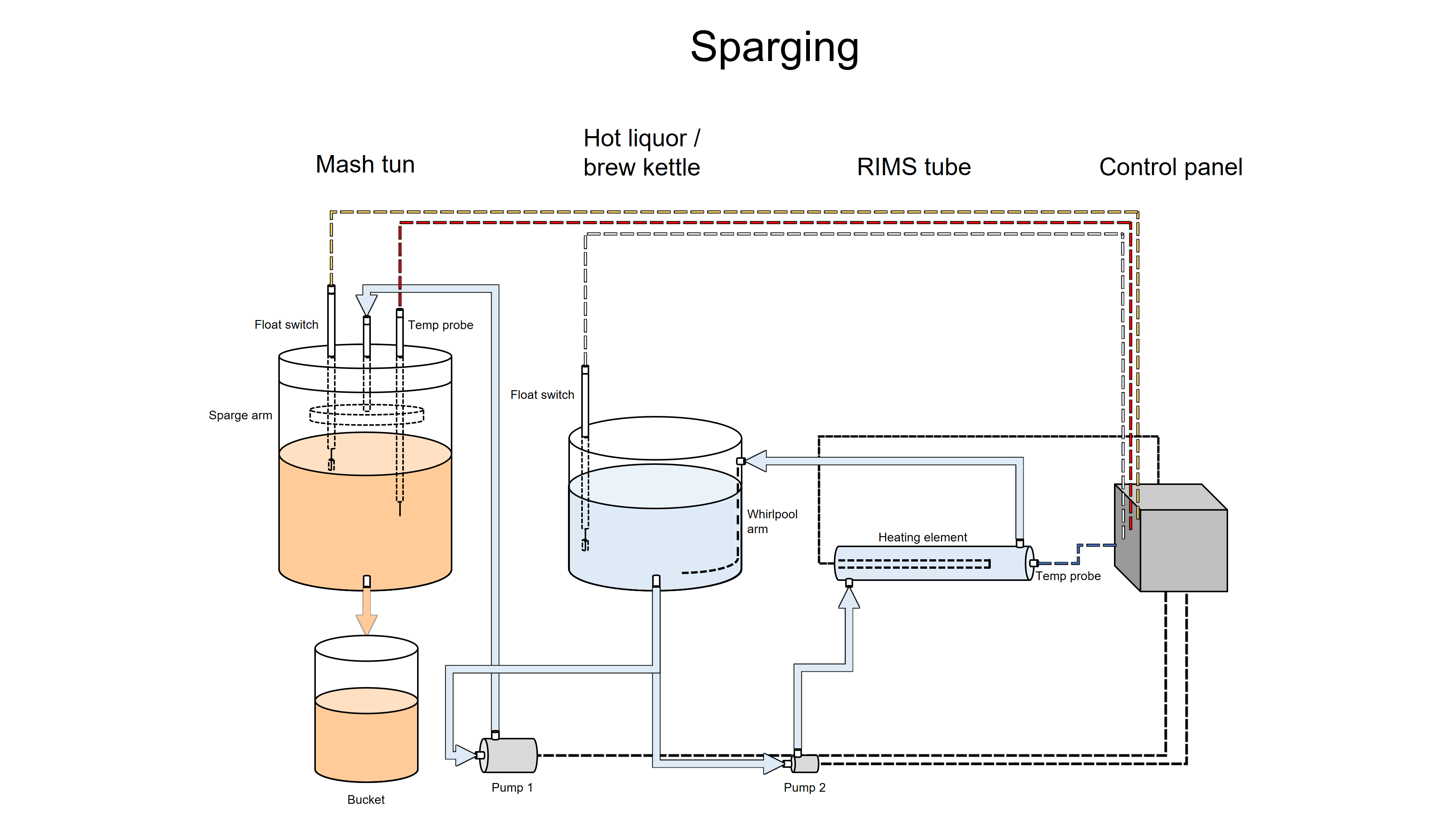

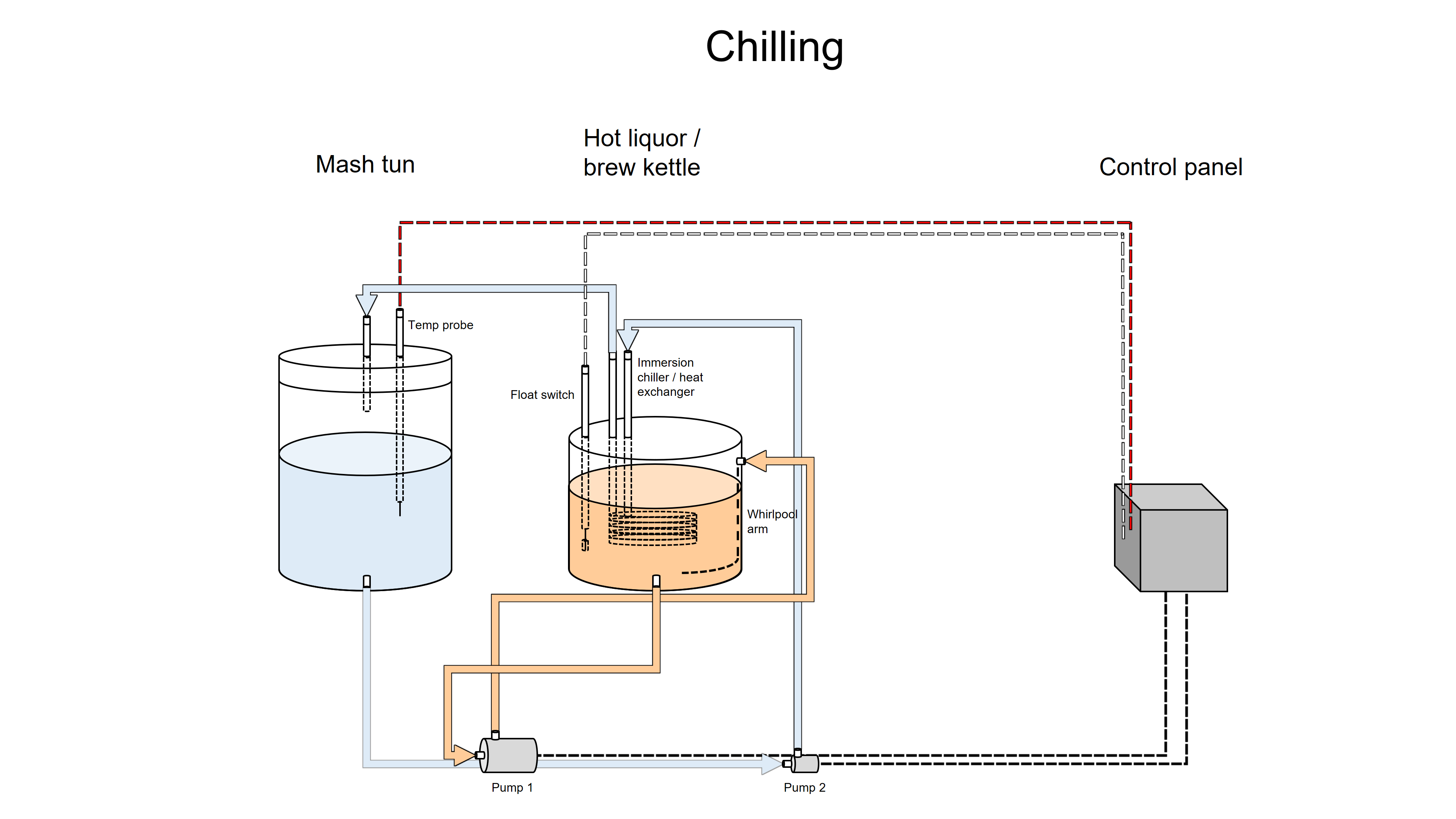

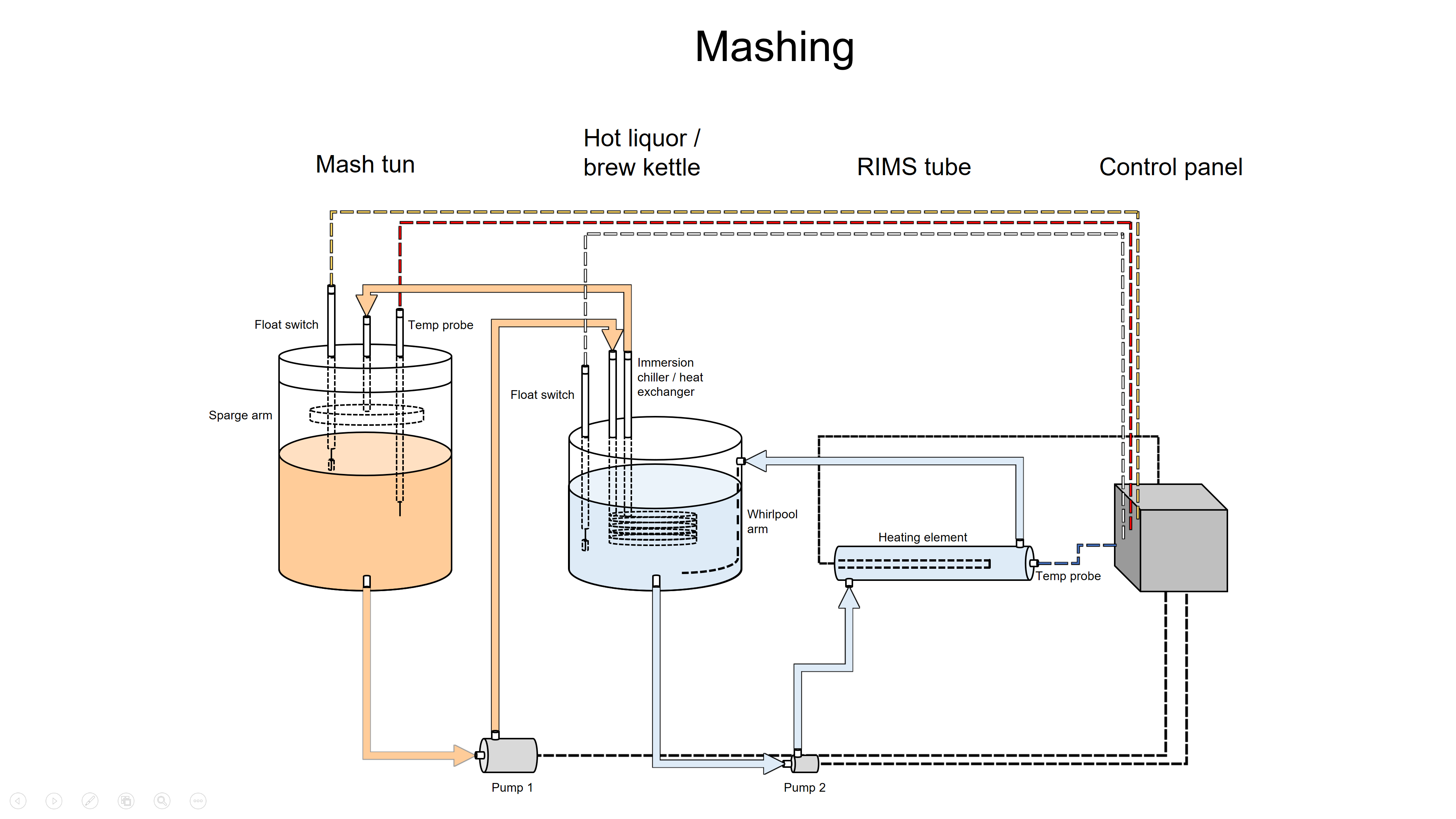

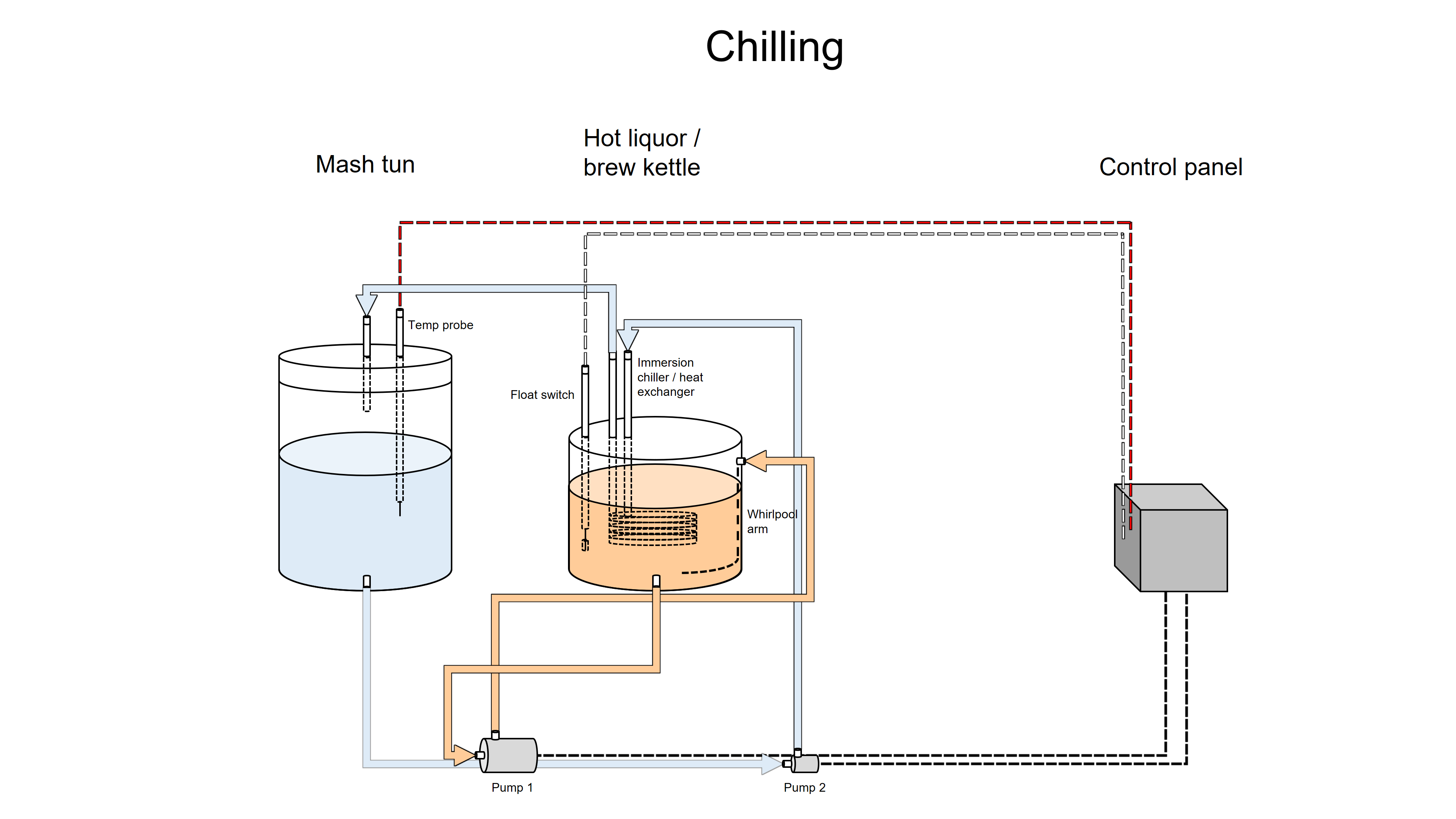

Experiment #2: Lightning fast half batch spargeless no boil BIAB for a sour. The idea here is to do sub-2-hour all grain half or smaller batch for something for which bittering isn't important (like a sour). Since I have a precision temp water bath, all I need is smaller vessel (i.e. a pot) that fits inside either my existing brew kettle or a tub. I can do a half-batch mash in a bag inside those smaller vessel using muslin bag or nylon BIAB bag, pull the bag, raise the temperature to pasteurization (exactly 170, just below the point at which DMS forms), chill by circulating water through chiller in an ice bath, rack to carboy. Just a matter of if I have the right sized vessels to make it work. Magic of the external RIMS tube: I can use basically any vessel (like a large tub or brew bucket, for example) for the outer hot water vessel.

Experiment #3: The great NEIPA hopsperiment. The idea is similar to above. Because you don't need a whole lot of bittering in an NEIPA, you could feasibly skip the boil. But what if, instead of using one vessel to mash in, you used, say, 5-10 small vessels, with a muslin bag in each vessel with an identical grain bill. And each one gets its own oz or two of hops at a "hop stand" during a long pasteurization and a dry hop later. And instead of racking each one, just using each vessel as its own fermentor with improvised air locks. What you get: 5-10 exactly identical extremely small batch NEIPAs with the only difference being the hops used. (Note: I can also add bitterness here by doing a separate 60 minute boil and dosing each subvessel with the resulting bitter wort.)

Note that you can technically do all of the above with either a standard RIMS tube (though you still need a vessel for water circulation) or a false bottomed HLT (though you are limited with vessel sizes). Convinced yet?