You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RIMS for Dummies

- Thread starter Sawdustguy

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I bent a piece of pipe to deliver back to the tun. Inside the tun I had a piece of silicone tubing to deliver wort on to of the mash, but not so it delivered directly down.

You don't run into channeling at all?

You don't run into channeling at all?

I haven't finished my build yet but I plan on recirculating like Kal does: http://www.theelectricbrewery.com/mash-lauter-tun?page=3

Doesn't get much simpler.

I haven't finished my build yet but I plan on recirculating like Kal does: http://www.theelectricbrewery.com/mash-lauter-tun?page=3

Doesn't get much simpler.

I'm convinced! Thanks for the link!

Now to just figure out what controller to use. Totally being productive at work today.

I haven't finished my build yet but I plan on recirculating like Kal does: http://www.theelectricbrewery.com/mash-lauter-tun?page=3

Doesn't get much simpler.

That's what I do.

I am building my tube this weekend, and found a really cool part on ebay that I thought I'd share.

It's a k-type thermocouple (they also have RTD if you prefer), with the probe being about 2 inches long, and mounted in a 1/2" NPT housing. That means you could likely get away with a shorter tube if you wanted to, and have less dead liquid sitting in the pipe.

It also has a detachable connector right at the end of housing. It uses a collar tightening method, not dissimilar to the way a faucet attaches to a shank. Quite looking forward to using this. I feel a little better about this method of disconnect versus a disconnect at the control box, so I can store the cable with the box, rather than having a cable hanging off the tube itself.

It's 304 stainless, so food safe and all that. It was 18 bucks shipped from china. I ordered on the 30th, and it arrived yesterday, so definitely pretty quick shipping, cheaper than the auber probs with the same pipe threads, and most importantly, it just looks freaking sweet. Super industrial and hefty.

It's a k-type thermocouple (they also have RTD if you prefer), with the probe being about 2 inches long, and mounted in a 1/2" NPT housing. That means you could likely get away with a shorter tube if you wanted to, and have less dead liquid sitting in the pipe.

It also has a detachable connector right at the end of housing. It uses a collar tightening method, not dissimilar to the way a faucet attaches to a shank. Quite looking forward to using this. I feel a little better about this method of disconnect versus a disconnect at the control box, so I can store the cable with the box, rather than having a cable hanging off the tube itself.

It's 304 stainless, so food safe and all that. It was 18 bucks shipped from china. I ordered on the 30th, and it arrived yesterday, so definitely pretty quick shipping, cheaper than the auber probs with the same pipe threads, and most importantly, it just looks freaking sweet. Super industrial and hefty.

I am trying to read through the whole thread now but wondering what the consensus is on placement and position. I've seen people going vertical... horizontal... above the tun...below the tun.... I'm thinking I might put mine horizontally above the tun to allow it to gravity drain easier when I turn the pump off?

I made mine so that it would swivel so that I can rock air bubbles out, and also rock water out when draining. As for hight in relation to the MLT, I don't know, mine is about half way up the side of the MLT because it's convenient.

I made mine so that it would swivel so that I can rock air bubbles out, and also rock water out when draining. As for hight in relation to the MLT, I don't know, mine is about half way up the side of the MLT because it's convenient.

Nice idea thanks. Do you have a tri clamp on the element side? I was thinking about doing that but in the end I could have just purchased Bobby's rims setup ha...

No, it's all NPT fittings. I was just too anxious to build one of these things and Bobby's rims tube wasn't in the budget, this was about $80 cheaper. I did use Bobby's bare element enclosure though, took a little rigging to get it grounded properly.

I was wondering if it was worth it to get a NPT 1.5" to 1.5" tri... https://www.brewershardware.com/1-1.5-Tri-Clover-X-1.5-Male-NPT.html so I can then connect bobby's tri clover enclosure to that for easy removal of the element? I've seen most guys get a good while out of theirs before they have to disassemble it by using PBW in it after brewing but it would be nice to be able to inspect it after each brew. Just not sure I want to sink more cash into it, got it pretty cheap as it is...

That plus this: https://www.brewhardware.com/product_p/etc3.htm

You're looking at $65 + shipping, the price of convenience. For the time being I'll do it the hard way, depending on how much of a PITA that is I may decide to work that into the budget down the road. I know that for many people that it's definitely worth it.

You're looking at $65 + shipping, the price of convenience. For the time being I'll do it the hard way, depending on how much of a PITA that is I may decide to work that into the budget down the road. I know that for many people that it's definitely worth it.

That plus this: https://www.brewhardware.com/product_p/etc3.htm

You're looking at $65 + shipping, the price of convenience. For the time being I'll do it the hard way, depending on how much of a PITA that is I may decide to work that into the budget down the road. I know that for many people that it's definitely worth it.

Ya I think I'll just stick with what I have. I have a box enclosure cord, etc, already so think I'll run that for a while and get the process down before I do any upgrades. In the end I'll probably just snag Bobby's tube but that will be a while.

Anyone know where I put my ground at?

A better description or link to the diagram you are trying to use would help a lot in any effort to help you.

Just saying... Wishing you great success in you plan.

P-J

I don't have the element yet but do have the tube, wire, and box ready... The previous owner grounded to the inside of the box, but he was using it on a pot. Not sure if it would be the same for a rims. I saw people running it to the tube itself.

View attachment 1423174212219.jpg

View attachment 1423174212219.jpg

You want to make sure that everything metal is connected to ground. Also you need to make sure you get a good seal and everything is water tight.

<EDIT> DELETED A BUNCH OF STUFF - I am an amateur and in no way qualified to give electrical advice. </EDIT>

Definitely check for continuity between your ground wire (at the other end of the power cord) to all metal parts on the tube with your multimeter.

<EDIT> DELETED A BUNCH OF STUFF - I am an amateur and in no way qualified to give electrical advice. </EDIT>

Definitely check for continuity between your ground wire (at the other end of the power cord) to all metal parts on the tube with your multimeter.

You want to make sure that everything metal is connected to ground. Also you need to make sure you get a good seal and everything is water tight. I would try first connecting my ground wire to the box on that green ground screw, then assemble like this: rims tube -> electrical box -> sealing o-ring -> heating element. IF that gets you a water tight seal the grounded box should ground the rest of the tube. Definitely check for continuity between your ground wire (at the other end of the power cord) to all metal parts on the tube with your multimeter.

The assembly I mentioned above wasn't water tight for me so I did rims tube -> o-ring -> electrical box -> o-ring -> heating element. I then took a bit of left over 12awg wire and secured an electrical connection between the already grounded electrical box and the NPT fitting externally.

OK thanks makes sense now. That was my next question, where so I place the o ring. I'm using bobby's enclosure and the solder flange on my pot and know that's how it works there and I've checked out builds on pots but not a whole lot on rims. Did you use the same o ring size inside and out, what 1" id? Just in case I need to go that route.

Dang, you saw my post before I could edit it. Know that I am an amateur and in no way qualified to give electrical advice.

I did need two 1" silicon o-rings, 1" to fit over the element threads.

Ha. I saw it. I hopefully plan to try and show everything I come up with to my wife's uncle who is. He is just an hour and half away so I want to get it all worked up and hopefully right before I take it over.

Hacky2447

Member

Is there a pre-built already wired RIMS system?

I know nothing about electrical and cannot solder to save my life.

I am looking at the wiring diagram and Im just like what are the symbols?

I know nothing about electrical and cannot solder to save my life.

I am looking at the wiring diagram and Im just like what are the symbols?

There are plenty of prebuilt RIMS tubes, check Blichmann, brewhardare.com, brewershardware.com.

As far as prebuilt systems go, there are prebuilt control panels like the ones at theelectricbrewery.com, and ebrewsupply.com but they are very expensive compared to DIY. I don't know that either of those solutions are as 'complete' as you'r looking for. (I think you'd still need to wire up your tube.)

FWIW I put together my rims system with zero soldering. The rims tube is pipe fittings so those screw together, and all the wiring uses crimped connections.

What wiring diagram are you looking at? Look for PJ's diagrams, they tend to use graphics of actual components rather than symbols, and they are color coded making them very easy to follow.

(edit) A whole bunch of PJ's diagrams: https://www.homebrewtalk.com/f170/list-pj-electrical-diagrams-382286/

As far as prebuilt systems go, there are prebuilt control panels like the ones at theelectricbrewery.com, and ebrewsupply.com but they are very expensive compared to DIY. I don't know that either of those solutions are as 'complete' as you'r looking for. (I think you'd still need to wire up your tube.)

FWIW I put together my rims system with zero soldering. The rims tube is pipe fittings so those screw together, and all the wiring uses crimped connections.

What wiring diagram are you looking at? Look for PJ's diagrams, they tend to use graphics of actual components rather than symbols, and they are color coded making them very easy to follow.

(edit) A whole bunch of PJ's diagrams: https://www.homebrewtalk.com/f170/list-pj-electrical-diagrams-382286/

Hacky2447

Member

Anyone have any experience with this?

http://www.amazon.com/dp/B00KUY388M/?tag=skimlinks_replacement-20

http://www.amazon.com/dp/B00KUY388M/?tag=skimlinks_replacement-20

Last edited by a moderator:

Hacky2447

Member

Think your better off at that price point going with bobby's tri clamp rims (brewhardware.com) for $130ish and adding an element and wire.

Yeah I am thinking about doing this. I just need to find a decent price on a pump, and temp control. The less wiring I have to do the better. LOL

Should have this setup in about 6 months or so.

misled_drummer

Well-Known Member

This is an older picture but here is my setup. My rims tube is mounted in the middle of the brewstand, and my control panel is in a toolbox. Works great but I'm thinking of getting a better enclosure for the control panel.

Anyone have any experience with this?

http://www.amazon.com/dp/B00KUY388M/?tag=skimlinks_replacement-20

Wow, that's almost exactly what I built.

Last edited by a moderator:

Wow, that's almost exactly what I built.

[/URL]

What's the connection at the bottom? Just curious.

misled_drummer

Well-Known Member

What's the connection at the bottom? Just curious.

Dump valve most likely.

Dump valve most likely.

Yes - dump valve. Makes cleaning a snap. It also traps small bits of malt.

Anyone have any experience with this?

http://www.amazon.com/dp/B00KUY388M/?tag=skimlinks_replacement-20

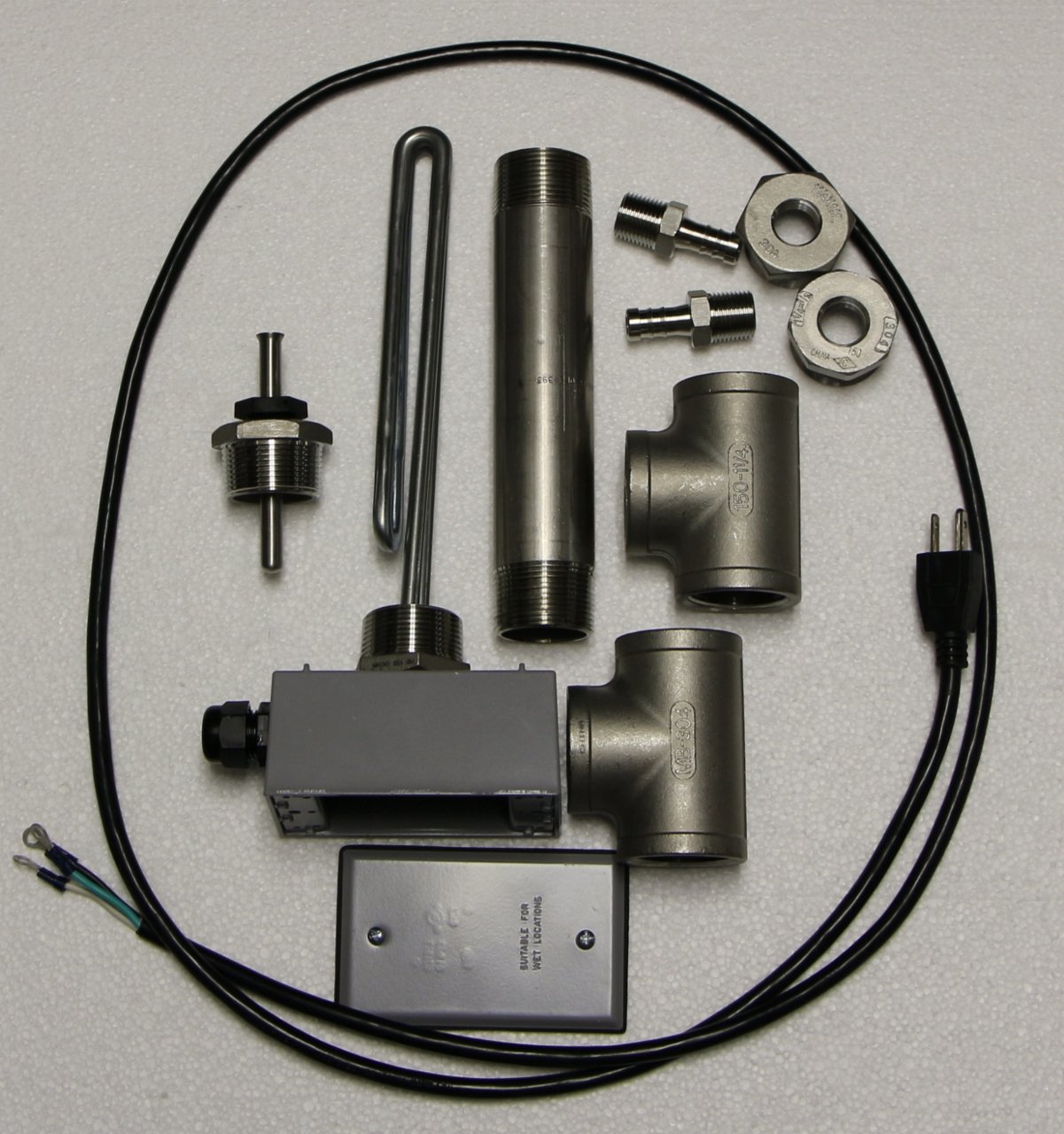

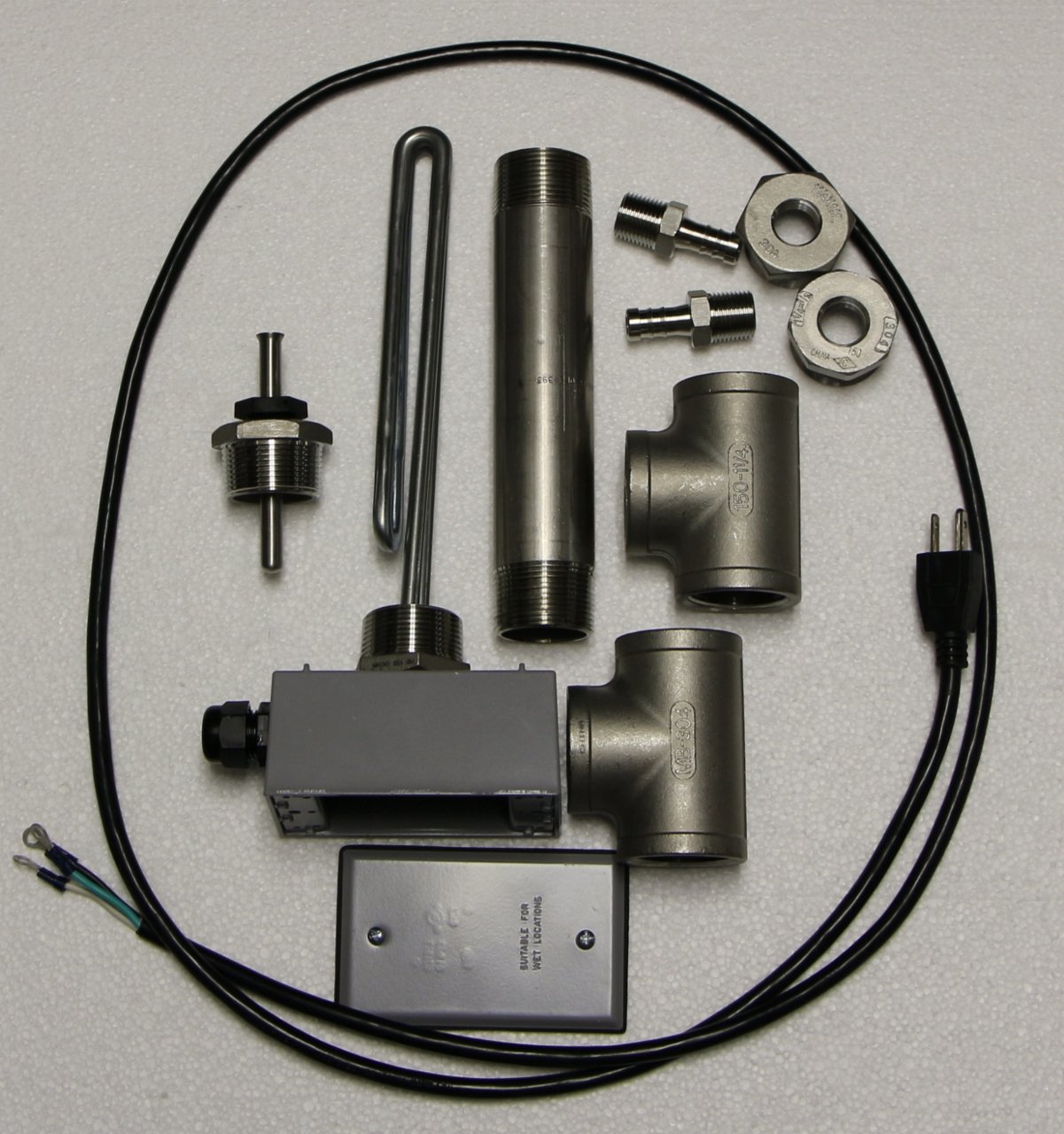

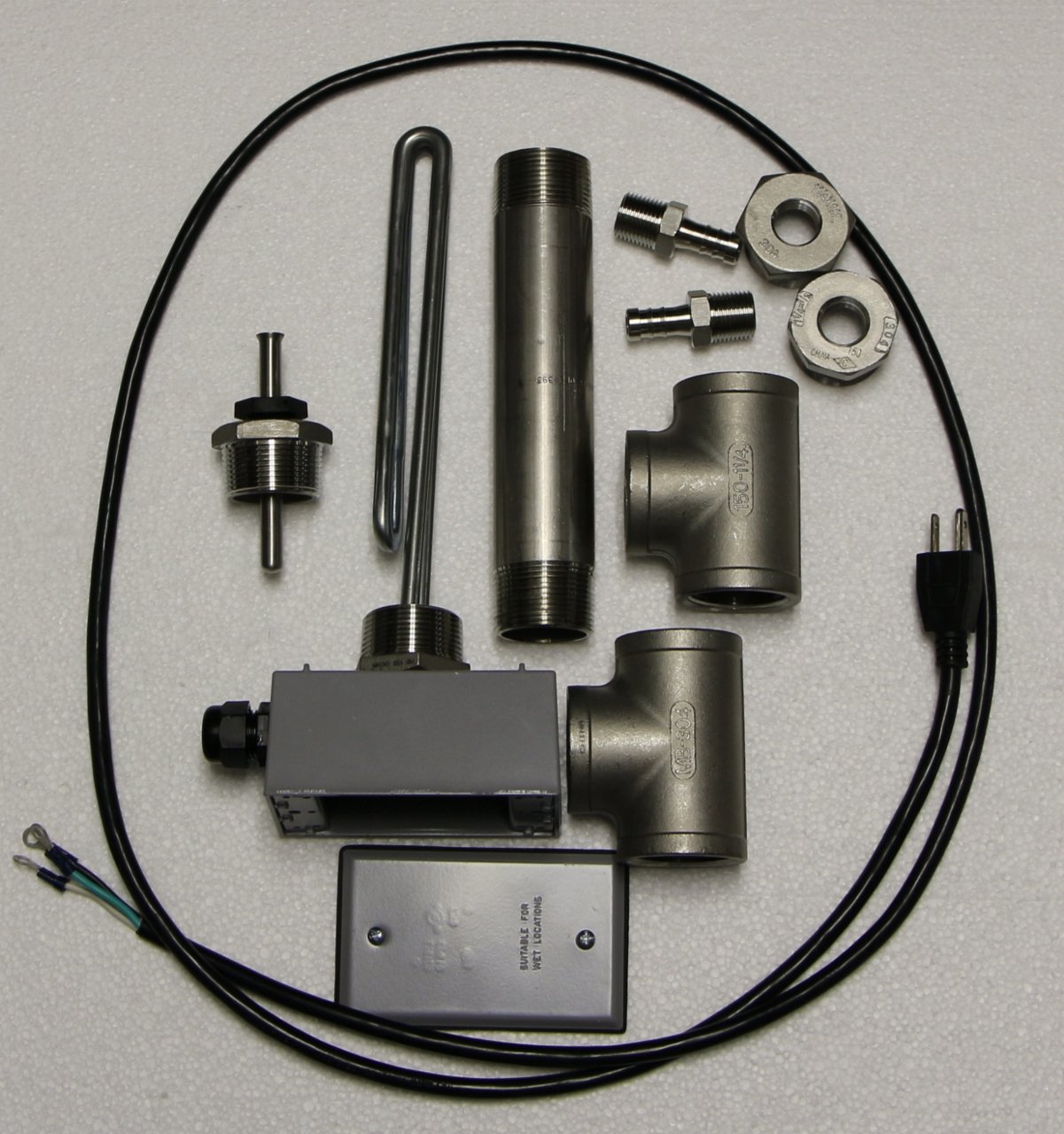

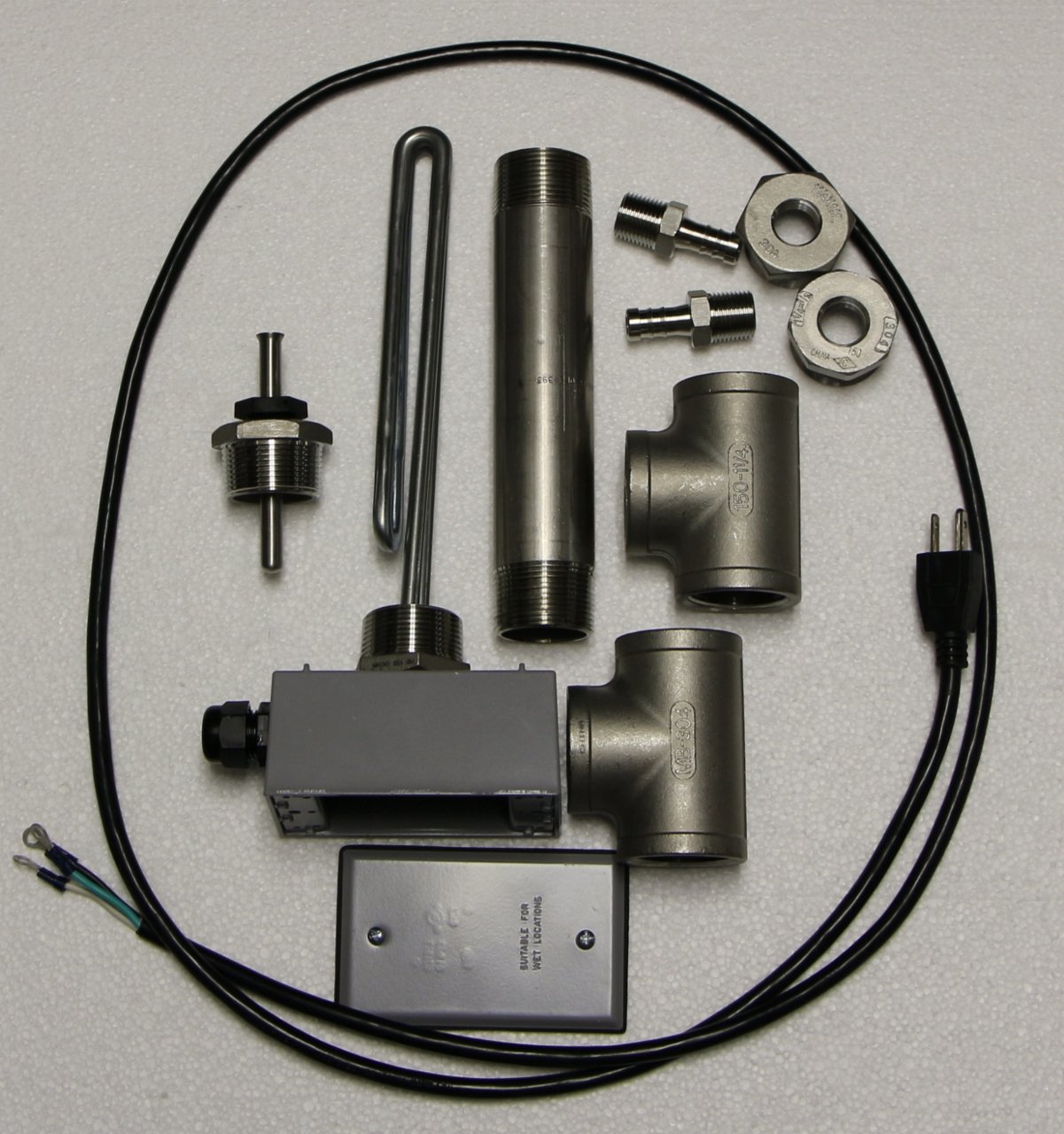

I actually purchased some of that stuff from that seller. I got his kit with the heater element pre- epoxied to the box and plug with the wiring rings already crimped on[Hyperlink Removed]. I purchased all the SS pipe separately Which came out to roughly $45 from amazon. I am kicking myself as I should have talked to my plumber ( I am a general contractor) and had him get me the pipe, probably could have saved a few bucks, or had him get me all copper.

I did buy his pre built control box [Hyperlink removed] Which while a little pricy, works just right, came calibrated to the temp probe, and has a full set of instructions geared for our use.

I have used this system twice now, and changing from a recirculated NON heated mash to this setup was a %12 improvement in efficiency. A couple more tweaks and Ill be at 80%.

My setup, I still need to mount the tube, and its all modular since I don't have space to leave it all setup, it works really well. I have a copper soldered manifold on the bottom of the cooler, and a scatter plate mounted to the top. I am actually talking with one of my subs who just works with custom stainless steel to make a insulated stainless steel mash tun.

I read this entire thread, start to finish over a few weeks before doing this. It is so much fun. I'm now able to do two 5 gallon batches in one day (takes about 9 hours including all the cleaning). We just got a two burner (65000btu burners) propane mobile stand, so looking for a second 10gal pot to speed things up even more.

Edit: removed hyperlinks to contentious products

Last edited by a moderator:

I actually purchased some of that stuff from that seller. I got his kit with the heater element pre- epoxied to the box and plug with the wiring rings already crimped on. I purchased all the SS pipe separately Which came out to roughly $45 from amazon. I am kicking myself as I should have talked to my plumber ( I am a general contractor) and had him get me the pipe, probably could have saved a few bucks, or had him get me all copper.

I did buy his pre built control box Which while a little pricy, works just right, came calibrated to the temp probe, and has a full set of instructions geared for our use.

I have used this system twice now, and changing from a recirculated NON heated mash to this setup was a %12 improvement in efficiency. A couple more tweaks and Ill be at 80%.

My setup, I still need to mount the tube, and its all modular since I don't have space to leave it all setup, it works really well. I have a copper soldered manifold on the bottom of the cooler, and a scatter plate mounted to the top. I am actually talking with one of my subs who just works with custom stainless steel to make a insulated stainless steel mash tun.

I read this entire thread, start to finish over a few weeks before doing this. It is so much fun. I'm now able to do two 5 gallon batches in one day (takes about 9 hours including all the cleaning). We just got a two burner (65000btu burners) propane mobile stand, so looking for a second 10gal pot to speed things up even more.

Nice, it works well going back into the cooler? What do you use to disperse it when going back in?

Last edited by a moderator:

I actually purchased some of that stuff from that seller. I got his kit with the heater element pre- epoxied to the box and plug with the wiring rings already crimped on. I purchased all the SS pipe separately Which came out to roughly $45 from amazon. I am kicking myself as I should have talked to my plumber ( I am a general contractor) and had him get me the pipe, probably could have saved a few bucks, or had him get me all copper.

I did buy his pre built control box Which while a little pricy, works just right, came calibrated to the temp probe, and has a full set of instructions geared for our use.

I have used this system twice now, and changing from a recirculated NON heated mash to this setup was a %12 improvement in efficiency. A couple more tweaks and Ill be at 80%.

My setup, I still need to mount the tube, and its all modular since I don't have space to leave it all setup, it works really well. I have a copper soldered manifold on the bottom of the cooler, and a scatter plate mounted to the top. I am actually talking with one of my subs who just works with custom stainless steel to make a insulated stainless steel mash tun.

I read this entire thread, start to finish over a few weeks before doing this. It is so much fun. I'm now able to do two 5 gallon batches in one day (takes about 9 hours including all the cleaning). We just got a two burner (65000btu burners) propane mobile stand, so looking for a second 10gal pot to speed things up even more.

I'm now suspicious of any one who's first post on this forum is talking about this amazon seller's merch. Is that you Tom Hargrave?

Just an FYI for those who aren't aware: apparently that guy likes to come on here from time to time with fake accounts posing as a very satisfied customer.

Last edited by a moderator:

I'm now suspicious of any one who's first post on this forum is talking about this amazon seller's merch. Is that you Tom Hargrave?

Just an FYI for those who aren't aware: apparently that guy likes to come on here from time to time with fake accounts posing as a very satisfied customer.

Im not sure if I should be offended or not. I have been lurking on these forums for years now as an excellent resource for advice. I also think the brew control guy is charging a stupid pile of money for the pipe kit, as its not even assembled. But that with reading all the people struggling to get all the right parts for the Aubrn PID systems working right, and many people lacking the tools/skill to make housings for them, that the pre built PID controller is actually a solid investment. My take away from these forums so far is that its a good place to share when your find something that does its job and does it well. If you read back there are tons of people recommending a variety of products from all over the place.

I don't know who Tom Hargrave is, or why he is relevant to this discussion. If he is someone who makes and sells brewing equipment, do you really thing his brewing setup would look anything like mine?

Im not sure if I should be offended or not.

If you're Mr Hargrave then I care about as much for your feelings as you do for ethics.

If your not then welcome to the forum! I ment no offense toward you, and I apologize if you were offended. Seriously.

...but if you are... For shame!

If you're Mr Hargrave then I care about as much for your feelings as you do for ethics.

If your not then welcome to the forum! I ment no offense toward you, and I apologize if you were offended. Seriously.

...but if you are... For shame!

I'm most certainly not Hargrave. I really don't understand both why you would think I was, and why this person is so terrible. Is he the brew-control seller on amazon?

dlaramie08

Well-Known Member

I'm most certainly not Hargrave. I really don't understand both why you would think I was, and why this person is so terrible. Is he the brew-control seller on amazon?

If you do a quick search for his name on this forum you'll see why he is so concerned that a: you are him and b: that you bought a product of his.

With all of this BS you begin to undestand why I do not join in on many treads any more. Way to much BS going on.

If you do a quick search for his name on this forum you'll see why he is so concerned that a: you are him and b: that you bought a product of his.

Well I had no idea that the amazon seller, and that guy were connected. Hence my confusion. All I knew is that I found something on amazon that did what I needed it to do. Im sorry that his reputation has sullied my recommendation, I will take you guys at your word that he is an unethical person and withdraw my recommendation. which is really a shame that his business practices are so bad, as the product I received is good. Always depressing to see someone ruin an otherwise good product with poor ethical decisions. Had I known anything about him, or known that he was brew-control then I would have made different decisions.

That being said, I hope that you can all rest assured that I am not that guy, and we can move on.

Similar threads

- Replies

- 1

- Views

- 526

- Replies

- 112

- Views

- 5K

- Replies

- 7

- Views

- 492

- Replies

- 9

- Views

- 811