Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

Back-story:

I've been running a RIMS mash tun for some time now. The RIMS tube is built from a 5500/1375w hot tub heater, Auber PID, and a 40amp SSR. It has been powered by 120v until now with great results.

My pump is a Chugger.

My boil and HLT has always been gas.

Current situation:

I recently moved into a house with a shed in the back yard set up with a 30A, 240v sub panel. I want to move to an all electric brewery in the shed.

Other loads are a 15 cft keezer and some florescent lights.

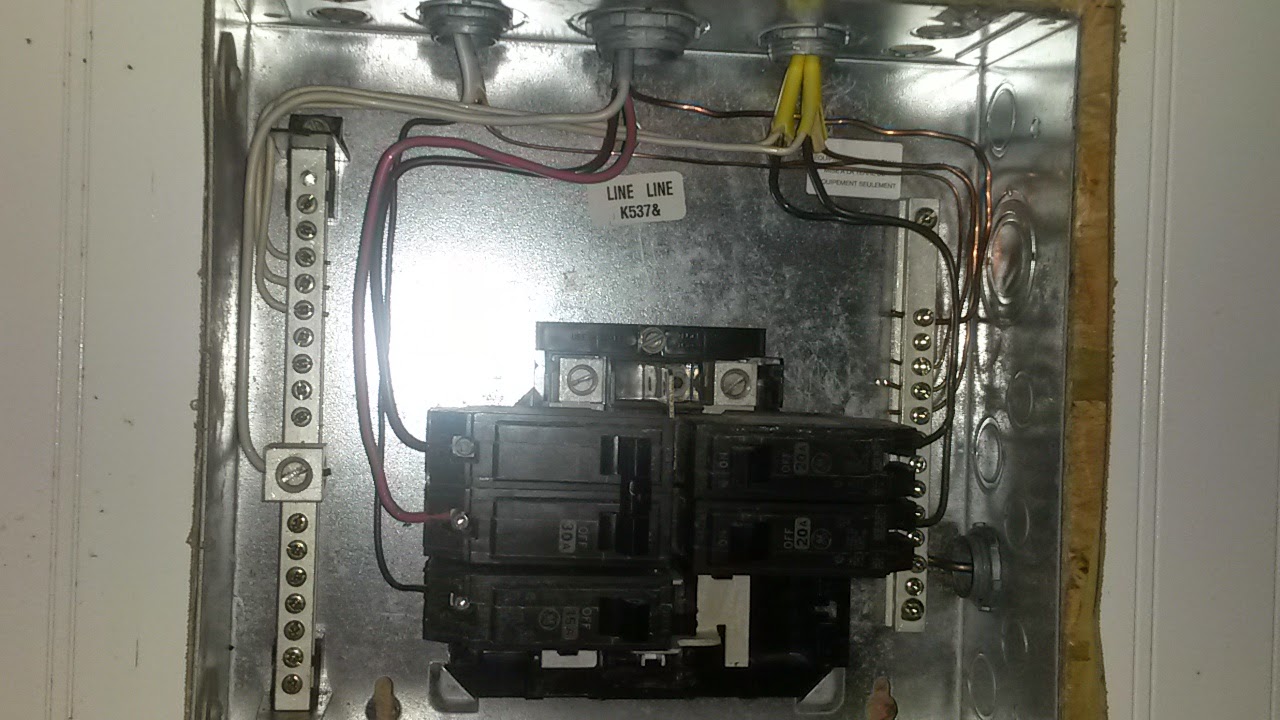

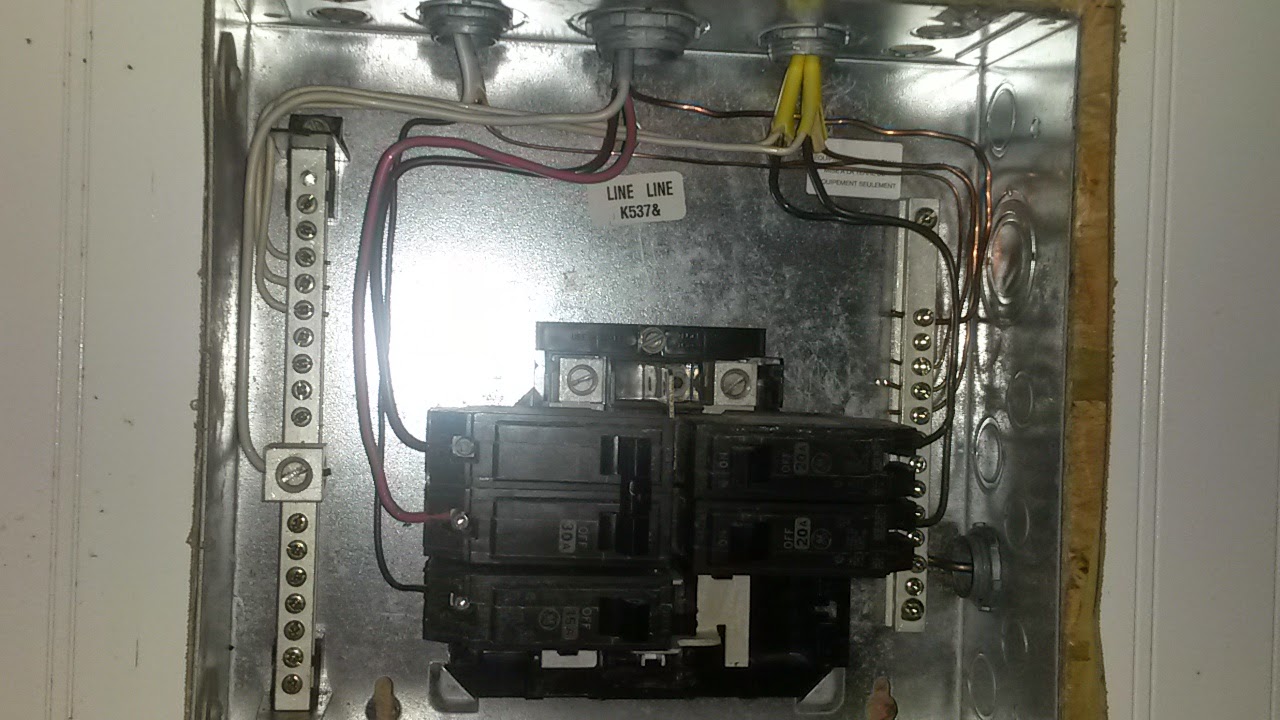

Call me crazy, but I'm pretty sure that line (red/black, top center) from the main panel should be tied directly to the rails on the sub-panel and not through a breaker.

I will need to set up a 240v line from the box, and I'm OK with that.

To get the full 30-amps for brewing, the keezer would have to be shut off during the brew. OK with that.

What to do:

I see a few ways of going forward from here:

1) Set up my current RIMS tube to run on 240v, build a 240v kettle, and never run the two at the same time (totally OK with that).

This leaves me questioning what to do for a HLT. I want to heat my sparge water while recirculating the mash. However, 23 amps for the RIMS + the pump puts me at 90% load on my sub panel, leaving no overhead for the HLT.

Seems problimatic unless the 240v RIMS tube can heat sparge water to 170 on demand.

"Back of the envelope" says that, in a magical RIMS tube with no heat loss, I could flow 16 gallons per hour and create 200F sparge water from a 60F source. Assuming 25% heat loss (just a SWAG), it should put out 165F water at 16 gallons per hour. Sounds like it might work.

I could even set up a switch to knock the RIMS back to 120v for the mash to prevent any possible scorching if I found that to be a problem.

Bonus: Eliminates the need for a pump from HLT to mash while pumping mash to kettle.

2) Keep the RIMS tube at 120v, then build a 120v HLT and a 240v kettle. Run the RIMS and HLT at the same time with the pump.

The "back of the envelope" thermo tells me that it would take, in a magical HLT with no heat loss, an hour and a half to take 8 gallons from 60F to 170F for sparging.

Doesn't sound good to me.

3) Scrap the RIMS tube, and build a HERMS setup using a 5500w HLT and a 5500w kettle.

Back of the envelope says 40 minutes to heat 15 gallons in the magic-HLT to 160 degrees (SWAG) for HERMS, then 5 minutes to heat to 170 for sparge.

Downsides seem to be learning a new system and the cost of the HERMS coil in the HLT.

Questions:

A) Does any one have experience in trying to use a RIMS tube as an on-demand water heater as proposed in (1)?

B) Does my analysis pass the smell-test?

I've been running a RIMS mash tun for some time now. The RIMS tube is built from a 5500/1375w hot tub heater, Auber PID, and a 40amp SSR. It has been powered by 120v until now with great results.

My pump is a Chugger.

My boil and HLT has always been gas.

Current situation:

I recently moved into a house with a shed in the back yard set up with a 30A, 240v sub panel. I want to move to an all electric brewery in the shed.

Other loads are a 15 cft keezer and some florescent lights.

Call me crazy, but I'm pretty sure that line (red/black, top center) from the main panel should be tied directly to the rails on the sub-panel and not through a breaker.

I will need to set up a 240v line from the box, and I'm OK with that.

To get the full 30-amps for brewing, the keezer would have to be shut off during the brew. OK with that.

What to do:

I see a few ways of going forward from here:

1) Set up my current RIMS tube to run on 240v, build a 240v kettle, and never run the two at the same time (totally OK with that).

This leaves me questioning what to do for a HLT. I want to heat my sparge water while recirculating the mash. However, 23 amps for the RIMS + the pump puts me at 90% load on my sub panel, leaving no overhead for the HLT.

Seems problimatic unless the 240v RIMS tube can heat sparge water to 170 on demand.

"Back of the envelope" says that, in a magical RIMS tube with no heat loss, I could flow 16 gallons per hour and create 200F sparge water from a 60F source. Assuming 25% heat loss (just a SWAG), it should put out 165F water at 16 gallons per hour. Sounds like it might work.

I could even set up a switch to knock the RIMS back to 120v for the mash to prevent any possible scorching if I found that to be a problem.

Bonus: Eliminates the need for a pump from HLT to mash while pumping mash to kettle.

2) Keep the RIMS tube at 120v, then build a 120v HLT and a 240v kettle. Run the RIMS and HLT at the same time with the pump.

The "back of the envelope" thermo tells me that it would take, in a magical HLT with no heat loss, an hour and a half to take 8 gallons from 60F to 170F for sparging.

Doesn't sound good to me.

3) Scrap the RIMS tube, and build a HERMS setup using a 5500w HLT and a 5500w kettle.

Back of the envelope says 40 minutes to heat 15 gallons in the magic-HLT to 160 degrees (SWAG) for HERMS, then 5 minutes to heat to 170 for sparge.

Downsides seem to be learning a new system and the cost of the HERMS coil in the HLT.

Questions:

A) Does any one have experience in trying to use a RIMS tube as an on-demand water heater as proposed in (1)?

B) Does my analysis pass the smell-test?

. I also have one, pot/ssr, on the BK. I have a PID doing the on off temp control going thru the Phase angle SSR that has a pot to control power. When I start spargeing, as soon as the wort is above the heater I turn on the heater with the PID set point to 200* and ssr at 100%. By the time I get done with the fly sparge the BK is at 200* and I turn up the pid set point well past 212* so the PID goes full on and I then use the pot/ssr to control the boil power. Saves lots of time not having to wait for the BK to boil.

. I also have one, pot/ssr, on the BK. I have a PID doing the on off temp control going thru the Phase angle SSR that has a pot to control power. When I start spargeing, as soon as the wort is above the heater I turn on the heater with the PID set point to 200* and ssr at 100%. By the time I get done with the fly sparge the BK is at 200* and I turn up the pid set point well past 212* so the PID goes full on and I then use the pot/ssr to control the boil power. Saves lots of time not having to wait for the BK to boil.