Jako

Well-Known Member

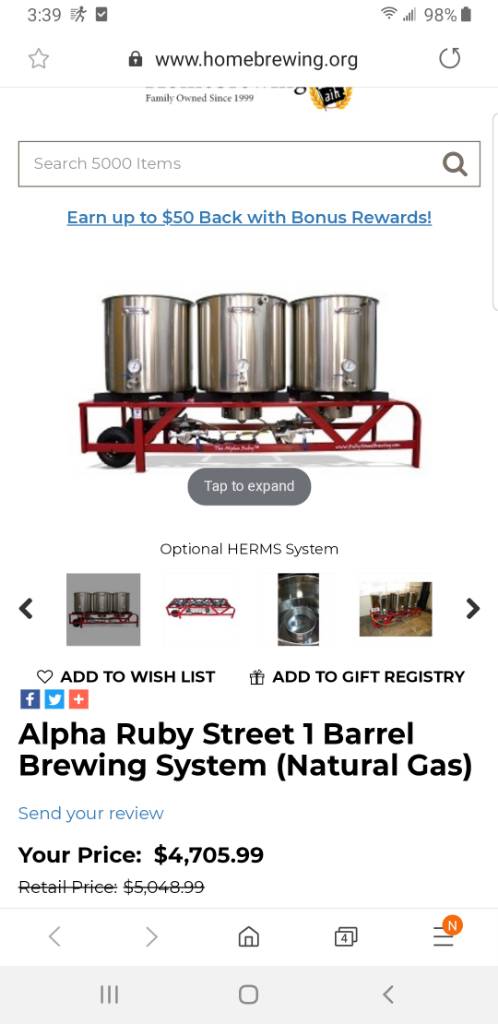

I am building a brewery and starting to plan a few things out. I want a 3 vessel system and i plan on running gas. Its what i prefer. i already have the SS brew tech BME boil kettle and plan on getting a SS mash tun and basic kettle. But past that i am not sure what i need. i currently have a ghetto 3 tier system and use the same kettle as my HLT and boil kettle. i gravity feed into my mash tun then heat the water and sparge. i collect wort in a kettle and bucket then once the my kettle is empty i toss in the wort and start the boil..

my goal with my new system is so i don't have to lift a thing. I am having a pot filler installed with a RO system feeding the pot filler. i am looking for help and ideas on how to build this out. i also love to see build systems so please share.

my goal with my new system is so i don't have to lift a thing. I am having a pot filler installed with a RO system feeding the pot filler. i am looking for help and ideas on how to build this out. i also love to see build systems so please share.