My current system has been running well for about 8 years or so.

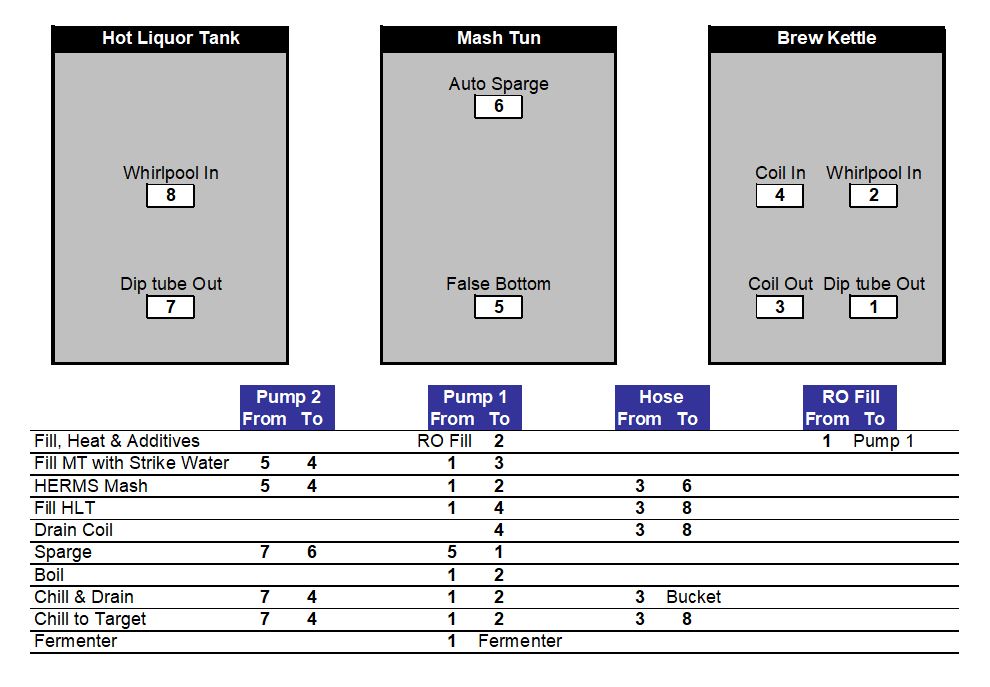

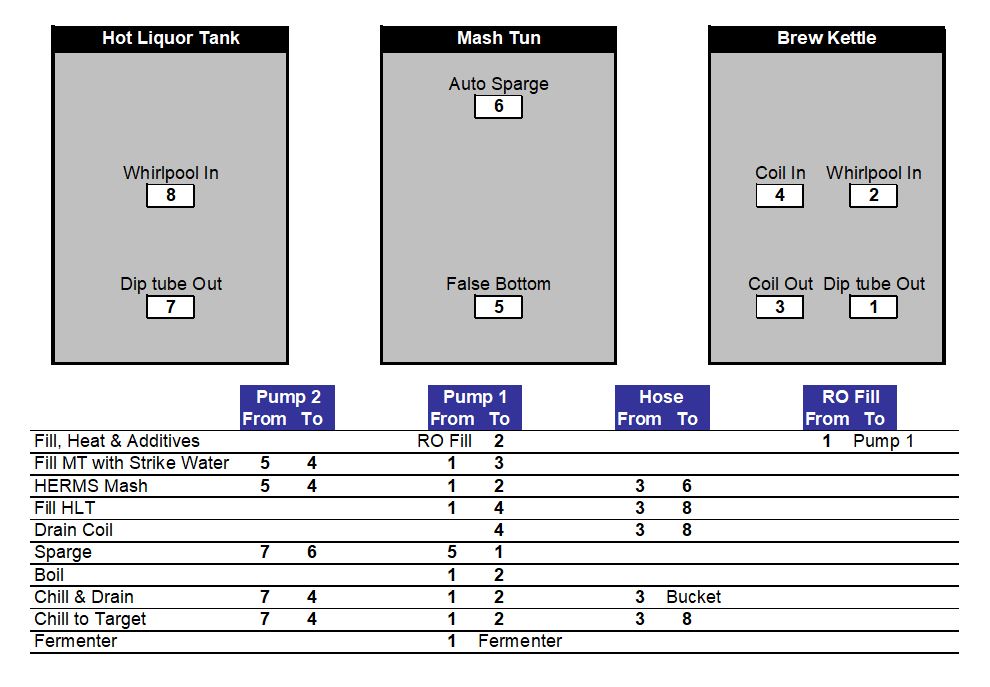

(3) 10 gallon stainless kettles

(2) Chuggar pumps

(1) 3,500 Watt Avantco induction cooker

I start by heating my combined volume of mash water and sparge water in my brew kettle on the left, typically 9.5 gallons.

I then pump my mash water to the center mash tun, mash in and set up a HERMS with a stainless built in coil in the left brew kettle.

After mashing, I pump all of the heated sparge water to the HLT on the left, often about 6 gallons or so. The left HLT has no heat source or coil.

To sparge, I pump from the HLT to a autospage in the center MT, and very slowly pump from the MT to the BK on the right, while starting the boil.

Works well, I have a total of about 9 hose changes. The HERMS coil in the BK is internally cleaned with the pumped sparge water and that same coil used to cool the wort, less to clean.

To cool the wort fast, I add large ice blocks to the HLT and pump that through the BK coil and back to the HLT.

I am happy with the set up, hitting about 82%-88% brew house efficiency.

I mill my grains on the fine side, so to avoid tannins I keep the PH at 5.3 and avoid sparging over 175F. One of the things I don't care for is after I bring my mash temp up to 170F coming out of the HEMS coil, I then pump the 178F to the HLT. That drops to about 176 in the HLT. I have the autospage set near the top on the MT, so at the start of the sparge the first water coming in is right around 175. Once the autosparge arm kicks in the hot water sits a long time in the pump and hoses and becomes much cooler.

I am considering changing to the following:

Replace the 10 gallon HLT and the 10 gallon MT with just a 16 gallon MT.

Rather then after the mash, pumping the sparge water from the BK to the HLT and then back to the MT, I would just pump all of the sparge water right on top of the mash in the larger BK. I would not need an autosparge in the larger MT.

I could then clean the larger MT during the boil and then fill it with the ice blocks to cool the wort.

My questions that come to mind,

* Would having a 16 gallon MT for just 5 gallon grain bills, with a less deep by wider grain bed have an adverse or positive effect? Would it take longer for the wort to clear and for the grain bed to set?

* Any disadvantage to having all of the sparge water sit on top of the grain bed right at the start of the spage? Would the clean spage water mix with the wort at the start and leave more sugar in the spent grain?

* Is there advantage to using cooler water for the end of the sparge, maybe as cool as 155F?

Thank you for any advice or suggestions!

Cheers!

David

(3) 10 gallon stainless kettles

(2) Chuggar pumps

(1) 3,500 Watt Avantco induction cooker

I start by heating my combined volume of mash water and sparge water in my brew kettle on the left, typically 9.5 gallons.

I then pump my mash water to the center mash tun, mash in and set up a HERMS with a stainless built in coil in the left brew kettle.

After mashing, I pump all of the heated sparge water to the HLT on the left, often about 6 gallons or so. The left HLT has no heat source or coil.

To sparge, I pump from the HLT to a autospage in the center MT, and very slowly pump from the MT to the BK on the right, while starting the boil.

Works well, I have a total of about 9 hose changes. The HERMS coil in the BK is internally cleaned with the pumped sparge water and that same coil used to cool the wort, less to clean.

To cool the wort fast, I add large ice blocks to the HLT and pump that through the BK coil and back to the HLT.

I am happy with the set up, hitting about 82%-88% brew house efficiency.

I mill my grains on the fine side, so to avoid tannins I keep the PH at 5.3 and avoid sparging over 175F. One of the things I don't care for is after I bring my mash temp up to 170F coming out of the HEMS coil, I then pump the 178F to the HLT. That drops to about 176 in the HLT. I have the autospage set near the top on the MT, so at the start of the sparge the first water coming in is right around 175. Once the autosparge arm kicks in the hot water sits a long time in the pump and hoses and becomes much cooler.

I am considering changing to the following:

Replace the 10 gallon HLT and the 10 gallon MT with just a 16 gallon MT.

Rather then after the mash, pumping the sparge water from the BK to the HLT and then back to the MT, I would just pump all of the sparge water right on top of the mash in the larger BK. I would not need an autosparge in the larger MT.

I could then clean the larger MT during the boil and then fill it with the ice blocks to cool the wort.

My questions that come to mind,

* Would having a 16 gallon MT for just 5 gallon grain bills, with a less deep by wider grain bed have an adverse or positive effect? Would it take longer for the wort to clear and for the grain bed to set?

* Any disadvantage to having all of the sparge water sit on top of the grain bed right at the start of the spage? Would the clean spage water mix with the wort at the start and leave more sugar in the spent grain?

* Is there advantage to using cooler water for the end of the sparge, maybe as cool as 155F?

Thank you for any advice or suggestions!

Cheers!

David

Attachments

Last edited: