- Joined

- Nov 24, 2017

- Messages

- 171

- Reaction score

- 82

I am putting my gas panel together for my Keezer. I have a 10 lb CO2 tank connected to a Primary Regulator tubed to a 3-Valve Secondary Regulator. Two ports of the secondary are tubed to 4-Valve Manifolds. All ports on the manifolds are off. I open the tank and adjust the regulator valves so I read something then shut the tank valve. All gauges hold pressure. I have sprayed the connections with soapy water and see no evidence of leaks. I come back after 6 to 8 hours and the gauges have dropped some. Come back the next morning and they are zeroed out. Is this normal or is this still considered a leak that needs to be resolved?

Thanks.

Thanks.

Last edited:

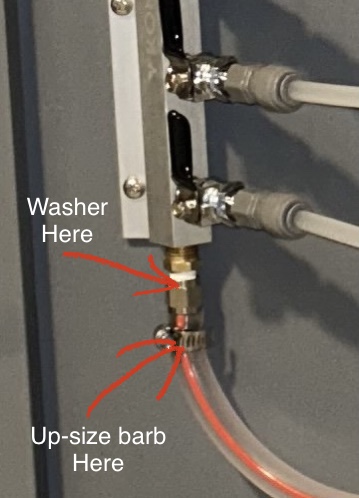

. Duct tape would have been classier

. Duct tape would have been classier . No doubt it must have been a PITA, I'm guessing but that's probably Evabarrier and the biggest common size for that is 9.5mmOD x 6.5mm ID making that a 1/4" on a 3/8".

. No doubt it must have been a PITA, I'm guessing but that's probably Evabarrier and the biggest common size for that is 9.5mmOD x 6.5mm ID making that a 1/4" on a 3/8". .

.