So I am using a wine fridge as a fermentation chamber and has worked out great so far! My question is, if u want a fermentation temp of 65 degrees, should I set the fridge at 65? I have read that temps within the vessel are normally 5 degrees warmer then outside temp during active fermentation, so should I set fridge to 60 until active fermentation subsides?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fermentation Temps

- Thread starter dordelli

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

petrolSpice

Well-Known Member

- Joined

- Dec 31, 2013

- Messages

- 833

- Reaction score

- 101

You need another way to determine the temp of the wort, like a probe taped to the side going to another temp sensor. A fermometer might work but they tend to be influenced by the ambient temp. Then set the temp of the cooler to whatever it needs to be to maintain the correct temp for the wort.

An better solution would be to use an external controller (like an STC-1000) to control when the cooler turns on, that way you do not need to use the cooler's temperature controller which is not really representative of what the wort temp. Plus, as fermentation activity varies (and wort internal temps fluctuate), the external controller will be able to account for it, whereas the coolers controller cannot.

An better solution would be to use an external controller (like an STC-1000) to control when the cooler turns on, that way you do not need to use the cooler's temperature controller which is not really representative of what the wort temp. Plus, as fermentation activity varies (and wort internal temps fluctuate), the external controller will be able to account for it, whereas the coolers controller cannot.

flars

Well-Known Member

The amount of heat produced by the fermentation is related to the OG of the wort. A wort with an OG of 1.1000 may produce a maximum increase in fermentation temperature of 10°. A wort with an OG of 1.042 may produce a maximum increase in fermentation temperature of 3°. The increase in temperature is gradual. Setting the refrigerator temperature control to hold the estimated maximum increase to your ideal fermentation temperature may stall the yeast for being to cold at the outset of fermentation.

Without a controller and probe attached to the fermentor it will require monitoring the wort temperature and manual adjustments of the refrigerator control.

I would suggest setting your refrigerators control to the low end of the yeasts optimum fermentation temperature range to begin. Adjust the temperature setting as fermentation activity increases and then begins to decrease.

Without a controller and probe attached to the fermentor it will require monitoring the wort temperature and manual adjustments of the refrigerator control.

I would suggest setting your refrigerators control to the low end of the yeasts optimum fermentation temperature range to begin. Adjust the temperature setting as fermentation activity increases and then begins to decrease.

Agree. If you don't use an external controller, then tape a temp probe to the carboy. You will have to watch the temp like a hawk, particularly during the first 2-3 days of fermentation, and frequently adjust the temp of the fridge to keep the beer where you want it.

Even if you use an external controller, I wouldn't tape that probe to the carboy. In my experience, that setup works great for keeping the beer from getting too warm. But it often causes it to get to cold. My current setup is (1) a chest freezer on a Johnson controller, (2) Johnson probe insulated and hanging near the bottom of the freezer, and (3) separate temp probe taped to the carboy. Still requires frequent monitoring, but it's the best setup I have found for maintaining constant fermentation temps.

Even if you use an external controller, I wouldn't tape that probe to the carboy. In my experience, that setup works great for keeping the beer from getting too warm. But it often causes it to get to cold. My current setup is (1) a chest freezer on a Johnson controller, (2) Johnson probe insulated and hanging near the bottom of the freezer, and (3) separate temp probe taped to the carboy. Still requires frequent monitoring, but it's the best setup I have found for maintaining constant fermentation temps.

I work in HVAC and have access to temp probes. You can purchase them from supply houses. My supplier BAPI makes stainless steel duct probes. I attached one to my lid (1/4" hole) and sealed it with silicone. Now I know my wort temp at the center and have better control. The problem with sticking them to the side is that the temp at the surface if the fermenter will be different than the wort. The vessel material plays a part and the probe is also in the ambient atmosphere too, which will throw off the temp.

raouliii

Well-Known Member

This has not been my experience with appropriate placement.....Even if you use an external controller, I wouldn't tape that probe to the carboy. In my experience, that setup works great for keeping the beer from getting too warm. But it often causes it to get to cold......

The consensus on HBT is that attaching the probe of an external controller, under a layer of insulation, to the side of a carboy or bucket is a VERY accurate way to control the fermentation temperature of wort, during active fermentation, through secondary. Accuracies below 1degF are consistently reported...... The problem with sticking them to the side is that the temp at the surface if the fermenter will be different than the wort. The vessel material plays a part and the probe is also in the ambient atmosphere too, which will throw off the temp.

Thanks guys, always great info on the HBT. I can't cut or drill holes in this fridge and it is in my kitchen where an external monitor (like HTC-1000) may look slightly out of place. I do intend on a more permanent chamber in the garage, so for now, I will monitor each batch with a probe on the fermenter and try to adjust down/up to where I need to be.

Then I disagree with the consensus. If you insulate the probe and attach it to the carboy, it will cause a big temp drop in the freezer, which will eventually cause the beer to drop too low. Example: controller setpoint is 67 with a 1 degree differential. Beer gets to 67 and the freezer kicks on. Due to the thermal mass of the beer, it takes a while for the temp to drop. In the meantime, the ambient temp in the freezer is in the 50's. Even after the freezer kicks off, the cold air in the freezer continues to lower the beer temp, causing unwanted swings. This was my experience until I moved the probe off the carboy.

In my experience attaching the probe to the side of the carboy(glass) works very well in my converted chest freezer. I can keep the temperature within +/- 0.3F, the immersion probe in the wort is rarely more than 1.0F above the glass temperature. Air temperature typically can get 10-15F below the glass temperature but has lower mass and less thermal energy so it doesn't overshoot the setpoint by more than 0.2F.

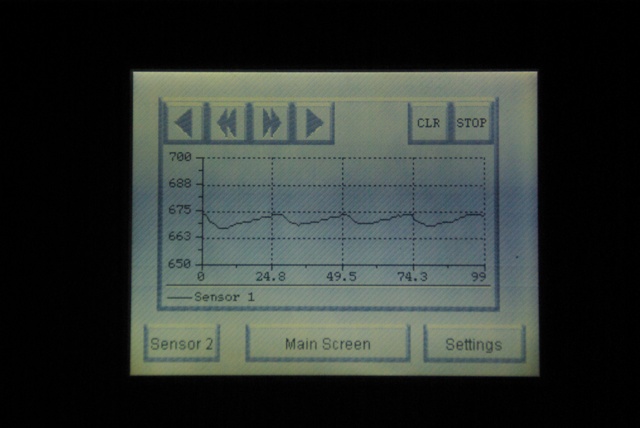

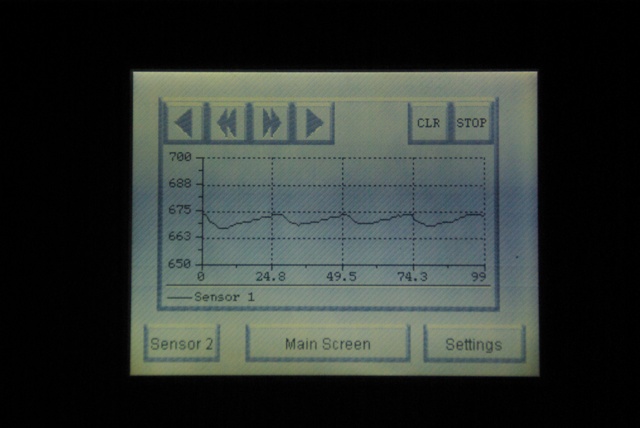

This is from an ale, carboy temp

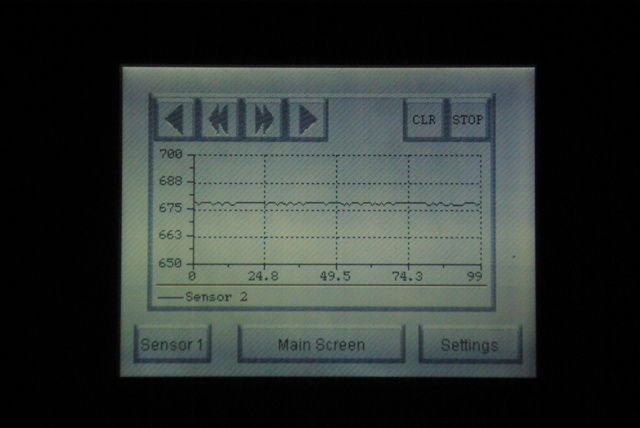

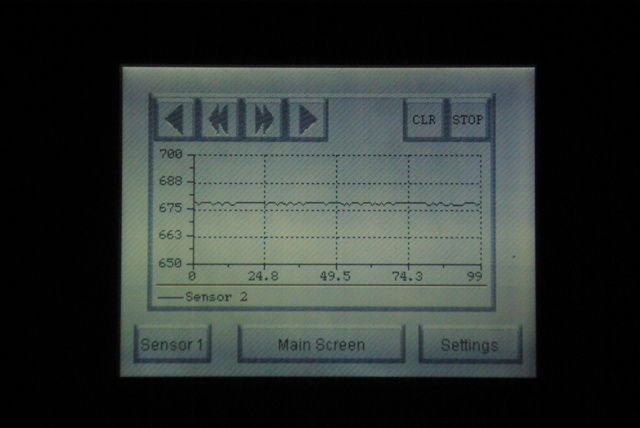

This is the corresponding immersion probe chart

Lagers follow similar pattern. These are 3hr data charts.

This is from an ale, carboy temp

This is the corresponding immersion probe chart

Lagers follow similar pattern. These are 3hr data charts.

I have the ability to control from any of the three probes; carboy, immersion, and air temperatures. I don't have any pictures from air temperature control. Keeping constant air temperature resulted in wort temp at set point shortly after time of pitching, gradually rising as fermentation picked up, to as much as 12*F(IIRC) above air temp. as ferment activity dropped the wort temp would gradually decline to the setpoint. Constant air temperature control also resulted in more frequent cycling of the freezers compressor.

Using the immersion probe for control had too much time lag for wort inside the carboy to cool and resulted in some wide temperature swings of the carboy temperature.

I experimented for the first few months, but carboy temperature control worked very well compared to the other two methods. So, I have only used the carboy sensor for control for over 3 years.

Using the immersion probe for control had too much time lag for wort inside the carboy to cool and resulted in some wide temperature swings of the carboy temperature.

I experimented for the first few months, but carboy temperature control worked very well compared to the other two methods. So, I have only used the carboy sensor for control for over 3 years.

Thanks, 02fx. Do you have dual-stage temp control (i.e., both heat and cold)? If not, how do you keep the beer from dropping down too low when freezer kicks on and drops the ambient temp 10+ degrees below the desired beer temp? Perhaps this is a climate-specific problem. I am near the coast in San Diego, so my outside temp is never that warm. After the freezer kicks in to cool down the beer a degree or so, it takes quite a while for the ambient temp in the freezer to warm back up from the 50's. In the meantime, my beer temp drops way too low.

Then I disagree with the consensus. If you insulate the probe and attach it to the carboy, it will cause a big temp drop in the freezer, which will eventually cause the beer to drop too low. Example: controller setpoint is 67 with a 1 degree differential. Beer gets to 67 and the freezer kicks on. Due to the thermal mass of the beer, it takes a while for the temp to drop. In the meantime, the ambient temp in the freezer is in the 50's. Even after the freezer kicks off, the cold air in the freezer continues to lower the beer temp, causing unwanted swings. This was my experience until I moved the probe off the carboy.

What you're describing is most often the result of pitching too warm. If you chill the wort to about 3*F below the target ferment (as you should anyway for cleaner flavor), fermenter temp variation should be little or none with the probe taped to the side of the bucket/carboy and insulated.

If you pitch at, for example, 74*F and put the probe in the air with the controller at 64*F, it can take many, many hours for the beer to reach 64*F especially as it will begin to produce some of its own warmth at some point. Having the temp probe hanging in the air or submerged in a separate vessel isn't a means by which you can accurately control a fermentation.

Thanks, Floyd. Good info. I try to pitch at or below fermentation temps. The problem I describe generally happens after the first couple of days (when the fermentation is not producing as much heat). I have read many of the forums on this issue, and it's not clear to me how others are keeping the temperature steady. Seems to make sense (to me, anyway): if the beer is 67 degrees and the ambient temperature in the freezer is 55, then the beer temp will continue to drop (unless there is a heat source).

Thanks, 02fx. Do you have dual-stage temp control (i.e., both heat and cold)? If not, how do you keep the beer from dropping down too low when freezer kicks on and drops the ambient temp 10+ degrees below the desired beer temp? Perhaps this is a climate-specific problem. I am near the coast in San Diego, so my outside temp is never that warm. After the freezer kicks in to cool down the beer a degree or so, it takes quite a while for the ambient temp in the freezer to warm back up from the 50's. In the meantime, my beer temp drops way too low.

I have heating on my controller, but I use it very rarely, only if I want to warm quickly. Usually the heater is just unplugged since I don't want the controller fighting itself between heating and cooling. Basement ambient is usually hovering around 68-70F year round so I'm almost always using cooling. Even if I'm doing a hefe or belgian wit at 70F.

I have my controller setup with a deadband and timer. So, as an example, setpoint is 50F, and deadband is 0.2F. If the temperature is greater than or equal to 50.2 for a minute, cooling turns on. Cooling stays on until the temperature is less than 50.2 for a minute, and turns off. The overshoot might be 0.2 or 0.3F, so the temp might drop to 49.8F. The resulting temperature swing of the glass is between 49.8 and 50.3

Similar threads

- Replies

- 24

- Views

- 2K