rebel_scum

Well-Known Member

- Joined

- Apr 12, 2014

- Messages

- 63

- Reaction score

- 11

hi all!

My first post here at HBT! I just competed my first extract brew (an irish stout) and I am struggling keeping it at a consistent temp, and I LOVE building stuff so...

After browsing these forums for hours and hours, I decided to embark on a new addition to my garage!

Total cost of this project so far has been around $250 including the fridge, which is much better than freezing my arse off in my house which I cooled down to 66 degrees to keep the beer cold enough in the closet upstairs.

Hope you like, and any advice is certainly welcome. I am quite sure this will get terribly out of hand if my aquarium build is any indicator.

Here's my progress so far, with a couple of questions at the end.

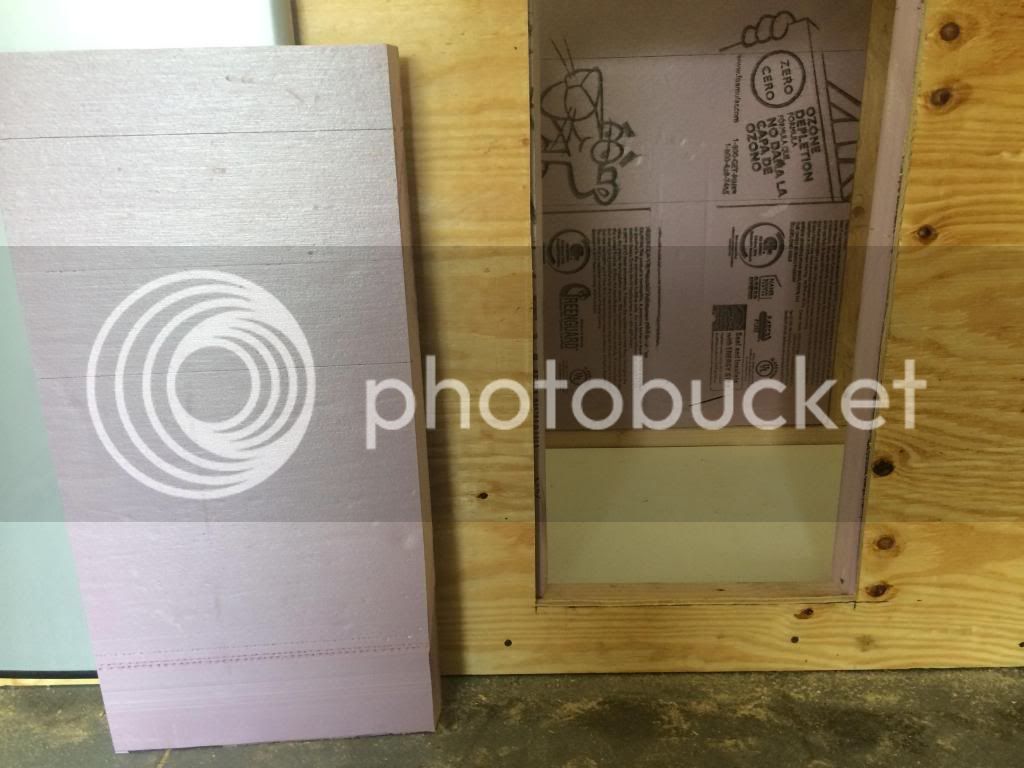

framing the mini fridge:

Added the end support:

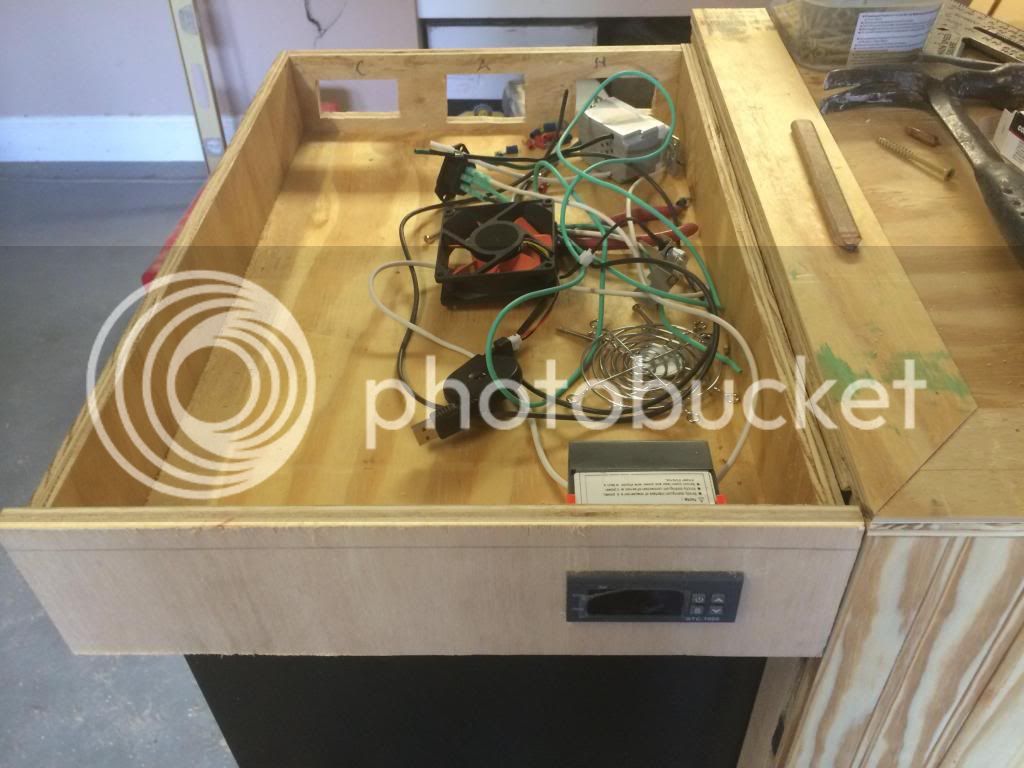

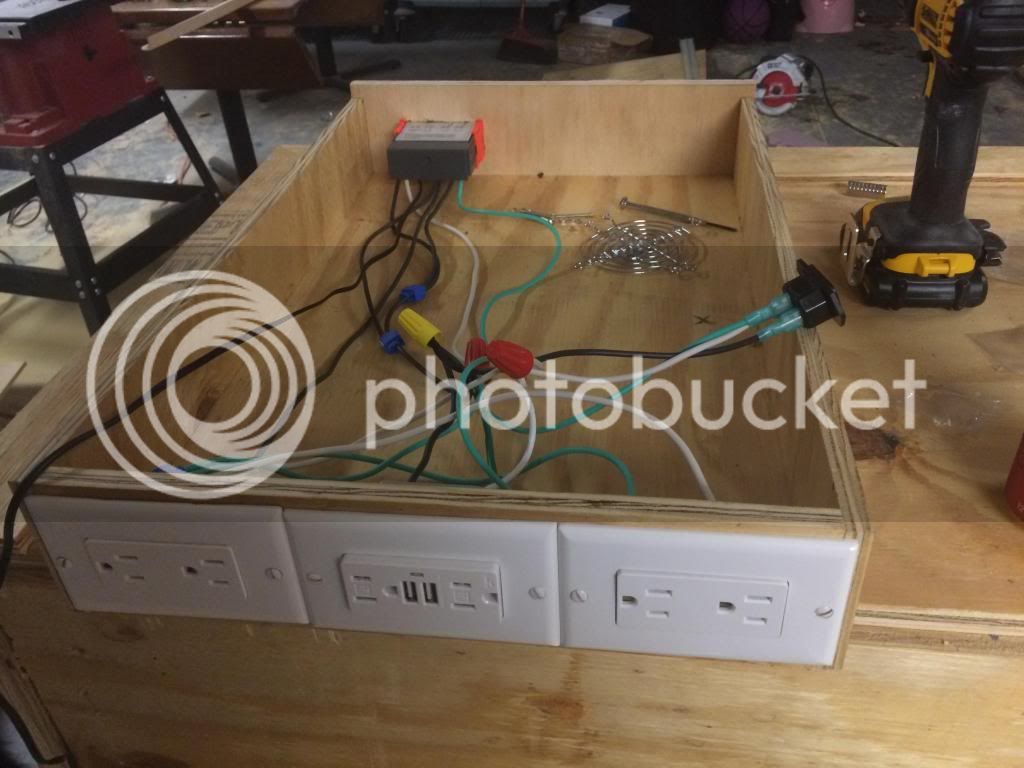

And the top:

Questions so far:

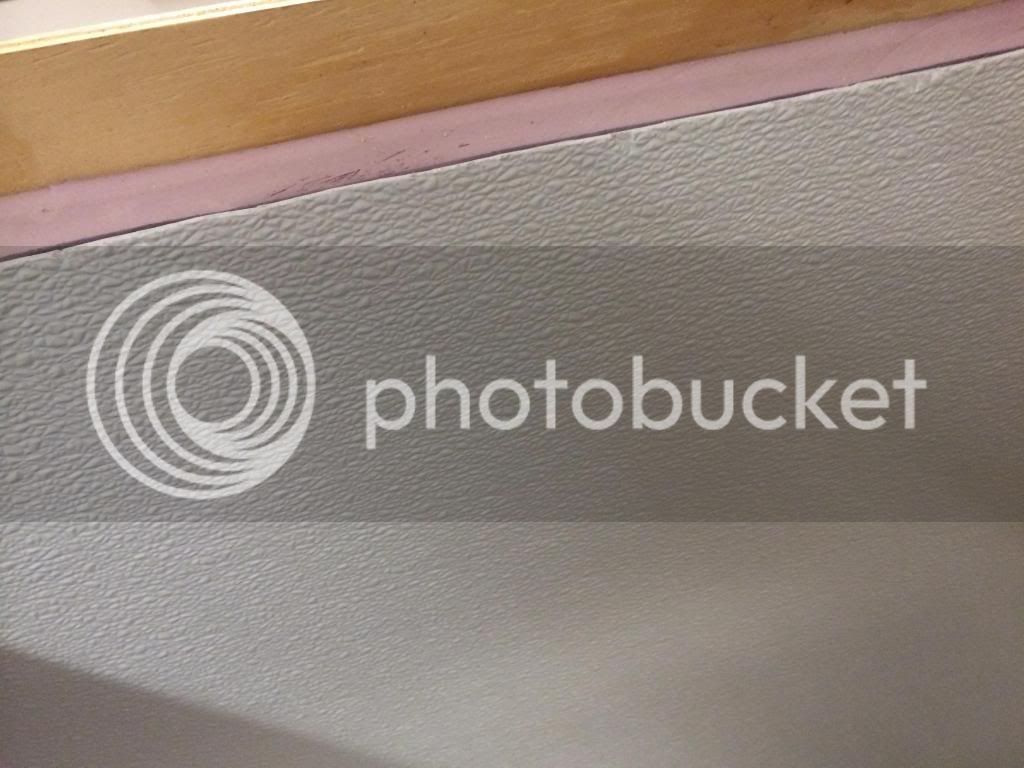

I have a 4x8 sheet of rigid foam insulation, R7.5 @ 1.5" thick. I intend to ply the bottom and cover it with FRP, would the insulation be better on the floor under the ply or should I ply the bottom and put the insulation on top between the ply and the FRP?

I am re-purposing the fridge door on the front of the cabinet, I would also like to add another door towards the end for easy access. any advice on getting a good seal on a wooden door?

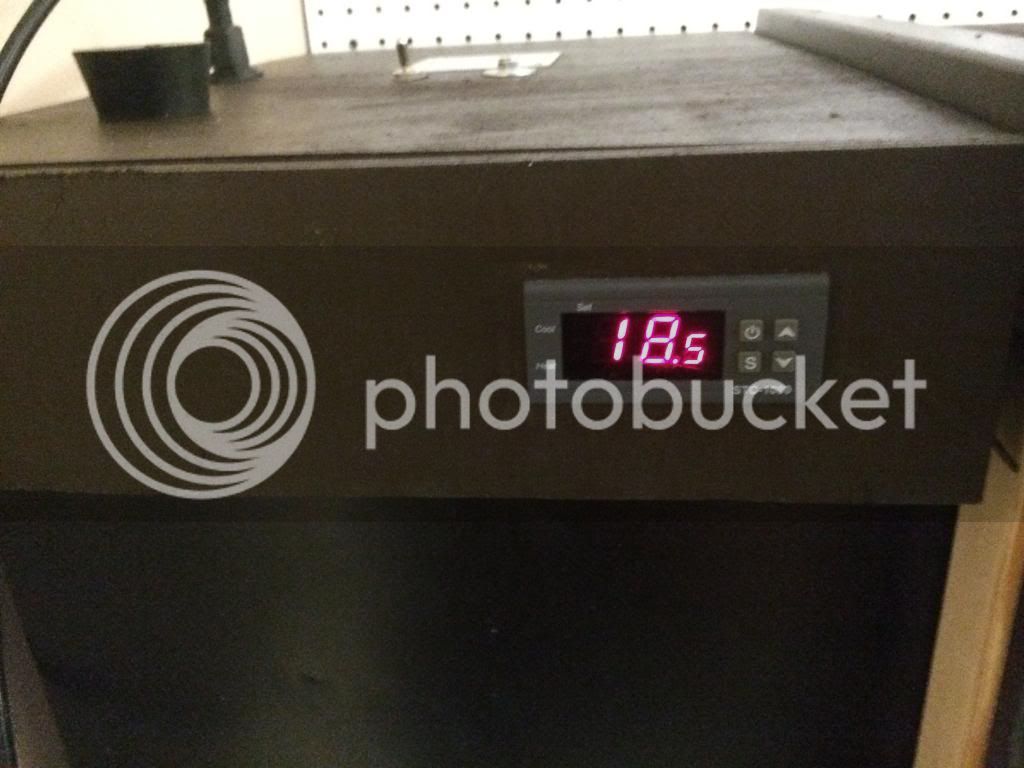

Also any links to a good, small ceramic heater or similar for the winter months would be awesome. I will be using a 2 cycle temp controller for the cooling and the heating respectively.

Thanks in advance for any help you can give me!

Jeff

My first post here at HBT! I just competed my first extract brew (an irish stout) and I am struggling keeping it at a consistent temp, and I LOVE building stuff so...

After browsing these forums for hours and hours, I decided to embark on a new addition to my garage!

Total cost of this project so far has been around $250 including the fridge, which is much better than freezing my arse off in my house which I cooled down to 66 degrees to keep the beer cold enough in the closet upstairs.

Hope you like, and any advice is certainly welcome. I am quite sure this will get terribly out of hand if my aquarium build is any indicator.

Here's my progress so far, with a couple of questions at the end.

framing the mini fridge:

Added the end support:

And the top:

Questions so far:

I have a 4x8 sheet of rigid foam insulation, R7.5 @ 1.5" thick. I intend to ply the bottom and cover it with FRP, would the insulation be better on the floor under the ply or should I ply the bottom and put the insulation on top between the ply and the FRP?

I am re-purposing the fridge door on the front of the cabinet, I would also like to add another door towards the end for easy access. any advice on getting a good seal on a wooden door?

Also any links to a good, small ceramic heater or similar for the winter months would be awesome. I will be using a 2 cycle temp controller for the cooling and the heating respectively.

Thanks in advance for any help you can give me!

Jeff