Yeah, wouldn't you think she'd see the obvious benefits?However it means the kitchen is no longer spotlessly clean every three weeks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Don't Do That.

- Thread starter TAK

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Broken Crow

Ale's what cures 'ya

- Joined

- Oct 12, 2020

- Messages

- 2,079

- Reaction score

- 2,626

It doesn't taste 'bad' per se, but it's lost all the detail and nuance...the oat contribution is completely absent. It taste a lot like a Coopers pre-hopped, partial-boil stout stout made with plain local tapwater. The freshness and complexity of fresh grains and hops is just gone or drowned out by what distinctly tastes like it's been diluted about 20% with my tapwater.That sucks. How does it taste?

I finally got around to cleaning the beer lines in my 6 keg, 4 tap keezer this weekend. Made up some hot PBW, disconnected all the kegs, ran the PBW through the lines and let it sit for about 90 minutes. After flushing the lines with fresh water, I was pretty proud of myself for finishing a job I had been procrastinating on for a few months. The next day, I needed to swap out an empty keg and I discovered that about 1 1/2 gallons of beer had leaked out of one of the kegs while the beer lines were disconnected and soaking with PBW. I had a good 4-6" of beer in the bottom of my keezer. Damn poppet! Well so much for procastinating on doing an entire keezer deep clean. So out came all 6 kegs and out came the shop vac, more hot PBW, some starsan and some elbow grease. Not how I expected to spend my weekend. The only good news is that I now have a shiny, sparkling clean keezer with clean beer lines!

Moral of the story? Don't procrastinate and always, always, always check the beer out post and poppet when you disconnect a keg! P.S. I bought a couple threaded caps that I put on beer out quick disconnects and keep them near the keezer. If I have to disconnect a beer line from a keg and I see a leak, I can now just cap the leaking post with one of these quick disconnects until its time to reconnect it to the beer line.

Moral of the story? Don't procrastinate and always, always, always check the beer out post and poppet when you disconnect a keg! P.S. I bought a couple threaded caps that I put on beer out quick disconnects and keep them near the keezer. If I have to disconnect a beer line from a keg and I see a leak, I can now just cap the leaking post with one of these quick disconnects until its time to reconnect it to the beer line.

Someone should make a beer QD without any output or poppet that one could snap on a beer post to seal it tight.

There was a recent thread regarding removing lines from kegs in kegerators when the owner was going to be on vacation. My take was it was probably the worst way to go as it exposes all the poppets to potential leaks, and it would be better to leave everything connected - as I always do. Much less likely to have a puddle with an attached beer QD, but for those then paranoid about faucets suddenly leaking while nobody is home, having a special beer QD to pop on when desired might be salve for their sensibilities

Cheers!

There was a recent thread regarding removing lines from kegs in kegerators when the owner was going to be on vacation. My take was it was probably the worst way to go as it exposes all the poppets to potential leaks, and it would be better to leave everything connected - as I always do. Much less likely to have a puddle with an attached beer QD, but for those then paranoid about faucets suddenly leaking while nobody is home, having a special beer QD to pop on when desired might be salve for their sensibilities

Cheers!

- Joined

- Nov 26, 2013

- Messages

- 7,670

- Reaction score

- 14,598

https://www.supplyhouse.com/CD-Valv...hopping_tm&utm_campaign=Shopping_TM_New_usersSomeone should make a beer QD without any output or poppet that one could snap on a beer post to seal it tight.

There was a recent thread regarding removing lines from kegs in kegerators when the owner was going to be on vacation. My take was it was probably the worst way to go as it exposes all the poppets to potential leaks, and it would be better to leave everything connected - as I always do. Much less likely to have a puddle with an attached beer QD, but for those then paranoid about faucets suddenly leaking while nobody is home, having a special beer QD to pop on when desired might be salve for their sensibilities

Cheers!

Exactly what I bought to cap a couple of beer out ball lock quick disconnects. They work great in a pinch when the poppet unexpectedly leaks.

I get using a standard MFL QD with a flare cap, but they get filled with beer I presume. I was thinking of a dedicated product that wouldn't have that problem...

Cheers!

Cheers!

Not very much beer, though, compared to the alternative. I guess I could always remove the disconnect's internal spring and plunger and fill it with epoxy or something else to minimize the amount of beer that would leak into the disconnect. The flare cap would just be extra insurance.

Now that I think about it, what if I leave the spring in but simply cut off the tip of the internal plunger so it can't press down on the poppet. The spring would still hold the remainder of the plunger with the o-ring/seal down to prevent beer from reaching the flare cap?

Now that I think about it, what if I leave the spring in but simply cut off the tip of the internal plunger so it can't press down on the poppet. The spring would still hold the remainder of the plunger with the o-ring/seal down to prevent beer from reaching the flare cap?

Cameronl

Well-Known Member

- Joined

- Mar 10, 2021

- Messages

- 160

- Reaction score

- 482

Plus it was a good excuse to buy a grandfather.

cut off the tip of the internal plunger so it can't press down on the poppet.

Might be asking a lot of that spring

I would put a quart of water in a keg, seal it up, attach your modified beer QD, then put on a gas QD and slowly charge the keg to see how much pressure the QD poppet spring can sustain...

Cheers!

- Joined

- Nov 26, 2013

- Messages

- 7,670

- Reaction score

- 14,598

agreed.I get using a standard MFL QD with a flare cap, but they get filled with beer I presume. I was thinking of a dedicated product that wouldn't have that problem...

Cheers!

Whoops missed this until now. According to Chris White, zinc added to the boil doesn’t really make it to the fermenter due to chelation. Unless you’re boiling in a Pyrex kettle that is.15 minutes before end of boil. Sometimes 10 if I forget.

If I recall, this is where it was discussed.

Perfecting Homebrewing Beer - Yeast Harvesting with Dr. Chris White (White Labs)

if not let me know and I’ll look again.

- Joined

- Feb 16, 2012

- Messages

- 3,356

- Reaction score

- 4,230

- Location

- Either in the brewery or on the road

File this one under "Stupid Grampa Tricks!"

Don't allow yourself to get distracted from the task at hand. After 5 weeks of slavishly nurturing a marvelous Timbo Pils, I allowed myself to be interrupted by two otherwise delightful twins who Face Timed their Grandmother before trundling off for the first day of First Grade. Grandma felt compelled to share the moment with me just as I was about to start a yeast/trub dump from the conical fermenter where the magical elixir had been spunding and cold crashing before kegging. Installed between the bottom TC port on the conical and the butterfly dump valve I have a mini-sight glass, so the geometry of the assembly is TC port-sight glass-dump valve. You can probably guess where this is going. If you remove the TC clamp above the sight glass instead of the one below the butterfly valve, there is no longer a valved shut-off to the tank.

DON'T DO THAT!!!

You wouldn't believe how quickly 7 gallons of finished beer under 1 BAR of pressure can pass through a 1.5" low-point orifice, splashing and spraying every imaginable nook and cranny, cabinet and shelving unit, floor and counter surface, within a 500 mile blast radius. The upside: I now have the cleanest brew area on the East Coast, although it took about seven hours of tedious labor to get it that way.

Don't allow yourself to get distracted from the task at hand. After 5 weeks of slavishly nurturing a marvelous Timbo Pils, I allowed myself to be interrupted by two otherwise delightful twins who Face Timed their Grandmother before trundling off for the first day of First Grade. Grandma felt compelled to share the moment with me just as I was about to start a yeast/trub dump from the conical fermenter where the magical elixir had been spunding and cold crashing before kegging. Installed between the bottom TC port on the conical and the butterfly dump valve I have a mini-sight glass, so the geometry of the assembly is TC port-sight glass-dump valve. You can probably guess where this is going. If you remove the TC clamp above the sight glass instead of the one below the butterfly valve, there is no longer a valved shut-off to the tank.

DON'T DO THAT!!!

You wouldn't believe how quickly 7 gallons of finished beer under 1 BAR of pressure can pass through a 1.5" low-point orifice, splashing and spraying every imaginable nook and cranny, cabinet and shelving unit, floor and counter surface, within a 500 mile blast radius. The upside: I now have the cleanest brew area on the East Coast, although it took about seven hours of tedious labor to get it that way.

ncbrewer

Well-Known Member

I don't have a conical, so I haven't done that. If I had one, I'm sure I would have. Sorry for your loss.You can probably guess where this is going. If you remove the TC clamp above the sight glass instead of the one below the butterfly valve, there is no longer a valved shut-off to the tank.

DON'T DO THAT!!!

So sad...If you remove the TC clamp above the sight glass instead of the one below the butterfly valve, there is no longer a valved shut-off to the tank.

DON'T DO THAT!!!

I almost did the same, and now I use red clamp nuts on below-waterline ports. Encourages me to think twice before doing something I'd regret.

https://www.brewershardware.com/San...tri-clover-compatible-clamp-nut-safety-dipped

- Joined

- Feb 16, 2012

- Messages

- 3,356

- Reaction score

- 4,230

- Location

- Either in the brewery or on the road

Me too. It was meant to be an entry for an upcoming competition, and I really had high hopes for this one. Fortunately I have five other beers either ready to go or in the final stages of conditioning that I can bottle and enter. But this one was the brew I'd spent the most time preparing for, ordering special malts and hops in addition to spending $$$. One of the more expensive beers I've brewed in a while, literally as well as figuratively.I don't have a conical, so I haven't done that. If I had one, I'm sure I would have. Sorry for your loss.

- Joined

- Feb 16, 2012

- Messages

- 3,356

- Reaction score

- 4,230

- Location

- Either in the brewery or on the road

That thought occurred to me several times during the extended clean-up. Back in the day when I still worked for a living, there were a number of different buttons and levers and circuit breakers, etc., that you wanted to be very careful NOT to activate without special forethought and purpose. Used to call 'em DFWI switches for "DON'T F*** WITH IT".So sad...

I almost did the same, and now I use red clamp nuts on below-waterline ports. Encourages me to think twice before doing something I'd regret.

https://www.brewershardware.com/San...tri-clover-compatible-clamp-nut-safety-dipped

I've used that approach on a couple of kegmenters I use that have 4" TC fittings. Knowing that mistakenly releasing those clamps with as much as potentially 2 BAR on the other side of the fitting could ruin my day even worse than yesterday's fiasco, I run a zip tie through the eyelet of the TC clamp and anchor it to some stationary piece of metal. It makes me double- and even triple-check my work before cutting the tie. There are some fittings "below the water line" that are safe and routine for activation without incurring disaster, but the ones that can result in heartbreak are the ones I'll secure with special attention getting features in the future. At least until my work area needs another deep cleaning.

- Joined

- Feb 16, 2012

- Messages

- 3,356

- Reaction score

- 4,230

- Location

- Either in the brewery or on the road

I got in touch with Brewershardware and they are out of both the red and green replacement eyelet nuts, but hope to be restocked by the end of September. It's comforting to know that I'm apparently not the only one who's suffered this ignominious fate. Thanks for the link.So sad...

I almost did the same, and now I use red clamp nuts on below-waterline ports. Encourages me to think twice before doing something I'd regret.

https://www.brewershardware.com/San...tri-clover-compatible-clamp-nut-safety-dipped

So sorry to hear this @Brooothru I dread that very task with every brew. I'm getting ready to dump trub from a new Fermzilla G3.2. It's a concern because it is so wobbly. But it has a couple of QC ports that I intend to use to release pressure. Hopefully it will work out.

I got a couple from the weekends brewday... here's how it started, Saturday evening prep the brewery, I brew with and e herms system, 15 gallon batch, so fill the hlt to about 20 gallon mark to cover the herms coil, and 12 gallons in the mash tun, hook up all hoses and set the temps on the control panel, go to bed. Here comes the eff up. Dont, dont wake up at 6, have your wife (who is my brew partner and brews her own sometime so she knows what shes doing) turn the system on, lay back down while its heating check it an hour later to find that she never actually switched the heating element to hlt, so, basically we circulated water for an hour just for fun, without heating anything, dont do that, just double check things 10 minutes in. I can see the look on ever lodo guys face right now as all that extra splashing was taking place for an hour before even heating things hahahaha. Oh well, the rest of the brewday went well, until the end so here's the other dont do that.

I have a pump that I have not yet mounted because I want to build a little shelf for it that I can slide in and out under my brew table. So here we go, after flame out hook up hoses to whirlpool for 15min, got an air bubble so the pump has a bleeder valve, at this point the pump isn't hot so I grab the unmounted pump and crack the bleeder, now that still almost boiling wort starts to flow and here I am with my hand in the quick connect fitting to get leverage on the air bleeder, it gets hot, fast. Dont do that, put gloves on like you always do, dummy. Some how I only blistered one finger.

I have a pump that I have not yet mounted because I want to build a little shelf for it that I can slide in and out under my brew table. So here we go, after flame out hook up hoses to whirlpool for 15min, got an air bubble so the pump has a bleeder valve, at this point the pump isn't hot so I grab the unmounted pump and crack the bleeder, now that still almost boiling wort starts to flow and here I am with my hand in the quick connect fitting to get leverage on the air bleeder, it gets hot, fast. Dont do that, put gloves on like you always do, dummy. Some how I only blistered one finger.

- Joined

- Feb 16, 2012

- Messages

- 3,356

- Reaction score

- 4,230

- Location

- Either in the brewery or on the road

I’m feelin’ your pain, brother! At least it was only blisters and not something worse. Like an entire lost batch. (I HATE it when I do that).I got a couple from the weekends brewday... here's how it started, Saturday evening prep the brewery, I brew with and e herms system, 15 gallon batch, so fill the hlt to about 20 gallon mark to cover the herms coil, and 12 gallons in the mash tun, hook up all hoses and set the temps on the control panel, go to bed. Here comes the eff up. Dont, dont wake up at 6, have your wife (who is my brew partner and brews her own sometime so she knows what shes doing) turn the system on, lay back down while its heating check it an hour later to find that she never actually switched the heating element to hlt, so, basically we circulated water for an hour just for fun, without heating anything, dont do that, just double check things 10 minutes in. I can see the look on ever lodo guys face right now as all that extra splashing was taking place for an hour before even heating things hahahaha. Oh well, the rest of the brewday went well, until the end so here's the other dont do that.

I have a pump that I have not yet mounted because I want to build a little shelf for it that I can slide in and out under my brew table. So here we go, after flame out hook up hoses to whirlpool for 15min, got an air bubble so the pump has a bleeder valve, at this point the pump isn't hot so I grab the unmounted pump and crack the bleeder, now that still almost boiling wort starts to flow and here I am with my hand in the quick connect fitting to get leverage on the air bleeder, it gets hot, fast. Dont do that, put gloves on like you always do, dummy. Some how I only blistered one finger.

- Joined

- Jan 3, 2020

- Messages

- 2,275

- Reaction score

- 2,359

We use a lot of white vinegar as we use it in the wash as a fabric softener and to release all the pet hair off the laundry. I have been using those gallon jugs to fill up extra RO water and most of those are labeled RO H20 in sharpie. Being a busy canning season, I had an empty that got filled with RO water but didn't get the sharpie. Over the weekend I was canning pickles and needed to get a yeast starter going so I grabbed a near full gallon of vinegar from the laundry and a gallon of RO water from the basement. I needed a big starter for a 10 gallon batch so I poured out the whole gallon of RO water, noticed it wasn't quite full, called it about 3.6 liters, weighed out 360 grams of DME and added it to the pot with lid. Then I started making a brine for the pickles, poured out the vinegar and a little voice inside said "why wasn't that gallon of RO water full". Tasted the "vinegar" in the measuring cup, it was flavorless, but the yeast starter on the stove sure had a nice tang to it!

Oh man, that sucks. I too am in canning mode and also have another starter to build to brew again this weekend... though I don't use RO so it would be pretty tough for that to happen. Hopefully you caught it before pitching the yeast.

- Joined

- Jan 3, 2020

- Messages

- 2,275

- Reaction score

- 2,359

I did catch it before then and before I processed the canner batch as well. Could have doublly sucked! And I had just gotten that delivery of DME so no delay in getting the starter.

Next don't do that with this brew was I had I great starter, brewed and I put the batch into a 10 gallon keg to ferment. Only my second time using kegs for fermenters. I knew I had a full batch, used fermcap and put a blow off tube on it. This second time I figured I should also take the poppet out of the keg post so the exit was wider. I was using the kegs so that I could conserve space in my ferm fridges. I have a ferm fridge that is convertible to a kegerator but the 10 gallon wouldn't clear the molded door shelves and the other chamber possiblity has a kolsch cold crashing. Said screw it, the garage is barely cool enough at about 70. Pitched the yeast. Next morning go to check it, no bubbles. I decide to check the prv, a tiny bit of pressure. I'm thinking maybe a little CO2 is trapped up against the lid as it was full. Check it later in the afternoon, no bubbles in the blow off container? I pull the prv, it starts hissing and spewing beer. I'm thinking, did I switch the floating dip tube? I throw a QD and tube on the other post. Beer is spilling out, foaming, under pressure. I get about a half gallon in two draws, still pressure. Then I realized I needed to also take the poppet out of the QD on the blowoff tube! Can't take that QD off though because the post hasn't got a poppet! Had to back the pressure down with the prv enough to get the blowoff tube off. It spit and spewed beer al over but I managed to drop the pressure. I told a buddy I wasn't wearing quite as much beer as I should have on this screwup! After getting the blowoff tube off, I scrambled and got the molded inside off the ferm chamber door and managed to fit the keg into the ferm chamber with a poppetless QD. Still have to fix the seal though as it the molded part held the seal in place, I had to tape the seal onto the door temporarily! On the plus side, It's a NEIPA and it smelled fantastic after the first round of dry hops, I could smell it at the top of the stairs.

Next don't do that with this brew was I had I great starter, brewed and I put the batch into a 10 gallon keg to ferment. Only my second time using kegs for fermenters. I knew I had a full batch, used fermcap and put a blow off tube on it. This second time I figured I should also take the poppet out of the keg post so the exit was wider. I was using the kegs so that I could conserve space in my ferm fridges. I have a ferm fridge that is convertible to a kegerator but the 10 gallon wouldn't clear the molded door shelves and the other chamber possiblity has a kolsch cold crashing. Said screw it, the garage is barely cool enough at about 70. Pitched the yeast. Next morning go to check it, no bubbles. I decide to check the prv, a tiny bit of pressure. I'm thinking maybe a little CO2 is trapped up against the lid as it was full. Check it later in the afternoon, no bubbles in the blow off container? I pull the prv, it starts hissing and spewing beer. I'm thinking, did I switch the floating dip tube? I throw a QD and tube on the other post. Beer is spilling out, foaming, under pressure. I get about a half gallon in two draws, still pressure. Then I realized I needed to also take the poppet out of the QD on the blowoff tube! Can't take that QD off though because the post hasn't got a poppet! Had to back the pressure down with the prv enough to get the blowoff tube off. It spit and spewed beer al over but I managed to drop the pressure. I told a buddy I wasn't wearing quite as much beer as I should have on this screwup! After getting the blowoff tube off, I scrambled and got the molded inside off the ferm chamber door and managed to fit the keg into the ferm chamber with a poppetless QD. Still have to fix the seal though as it the molded part held the seal in place, I had to tape the seal onto the door temporarily! On the plus side, It's a NEIPA and it smelled fantastic after the first round of dry hops, I could smell it at the top of the stairs.

So yesterday I pressure-transferred my last batch of beer from my Fermzilla Tri-conical into a keg. Being a little short on time, I deferred cleaning to today. Moved the fermenter to the sink to dump out the trub, and removed the bottom tri-clamp fitting. Without relieving pressure. Yeah, don't do that.

That sparks visions of your fermzilla flying around the room making a 'fffffbbbbbttt' sound like a balloon. I removed the lid of my fermzilla all-rounder ONCE with 5psi in it, lucky I emerged unbruised as it flew a few feet in the air.So yesterday I pressure-transferred my last batch of beer from my Fermzilla Tri-conical into a keg. Being a little short on time, I deferred cleaning to today. Moved the fermenter to the sink to dump out the trub, and removed the bottom tri-clamp fitting. Without relieving pressure. Yeah, don't do that.

Question: how high up the wall did the trub/gunk go?

The highest I saw any was about 6' up from the floor (which would be 3-4' up from where the base of the fermenter was at the time). But it got some range--there was some on the door, some 10' away. But no one was hurt and nothing damaged--just a heck of a mess.Question: how high up the wall did the trub/gunk go?

Don't forget to unplug your temp probe before moving the kettle from the brew table to the sink for cleaning, now I gotta bust out my soldering skills.

Tricky fix that one, I'd recommend putting the connector into a clamp, heating each wire and then pulling rapidly to try and clear as much solder from the pin bucket as possible. If you have a solder pump, then you can reheat the bucket and suck the solder out. If not, grip the connector with a pair of pliers, reheat the bucket and tap the connector bucket down on something hard to jolt the liquid solder out.Don't forget to unplug your temp probe before moving the kettle from the brew table to the sink for cleaning, now I gotta bust out my soldering skills. View attachment 828083

I think a did pretty good on clearing the old solder out of the buckets, wires back in and soldered tight. The third one was tough since I had less room to work. All back together and I'll test it later tonight.

I’ve got a 5 gallon batch that’s been fermenting for an event on Saturday, so last night I wanted to dry hop with a little bit of cryo pellets and while doing that, the brew jacket rod and sleeve slipped out of the bung … bam into the fermonter. Ef ef ef. DON’T DO THAT! With Starsan on my hands I reached into grab the unsanitary end which did not touch the beer, thankfully rinsed and dried it throughly. I had recently cracked my 3 gallon fmonster so I checked for a leak on this one. Whew, can’t wait to get this one kegged and out of here.

Don't grab a pack of bittering hops out of the fridge, check the AA and say "that's perfect" but neglect to notice that it's a 2 oz package before you dump the whole thing into the boil. Guess my English pale ale is an English IPA now.

Use a pistol grip hose nozzle to rinse the inside of the bottles if it fits snugly using city water presure- yea, they explode -DONT DO THAT.

- Joined

- Nov 26, 2013

- Messages

- 7,670

- Reaction score

- 14,598

Kids, public safety announcement here.

Check yer defaults.

On everything.

Always.

Then check then again. (I feel like Nemo's dad darting in and out of Annie the Sea Anemone multiple times)

Anyway, if you use an STC1000+ and have ramp schedules programmed, and you write them down, but you edit them sometimes and forget to write down starting temp for instance, then this can happen.

"Set ramp to 68-74 over 48 hrs" but step 0 temp was still 64 not 68 as written...

Don't do that.

Funny side story, I had *JUST* had a convo with @day_trippr about defaults and checking them not 48 hrs ago.

Some people just cannot be trusted with tech.

Check yer defaults.

On everything.

Always.

Then check then again. (I feel like Nemo's dad darting in and out of Annie the Sea Anemone multiple times)

Anyway, if you use an STC1000+ and have ramp schedules programmed, and you write them down, but you edit them sometimes and forget to write down starting temp for instance, then this can happen.

"Set ramp to 68-74 over 48 hrs" but step 0 temp was still 64 not 68 as written...

Don't do that.

Funny side story, I had *JUST* had a convo with @day_trippr about defaults and checking them not 48 hrs ago.

Some people just cannot be trusted with tech.

InspectorJon

Well-Known Member

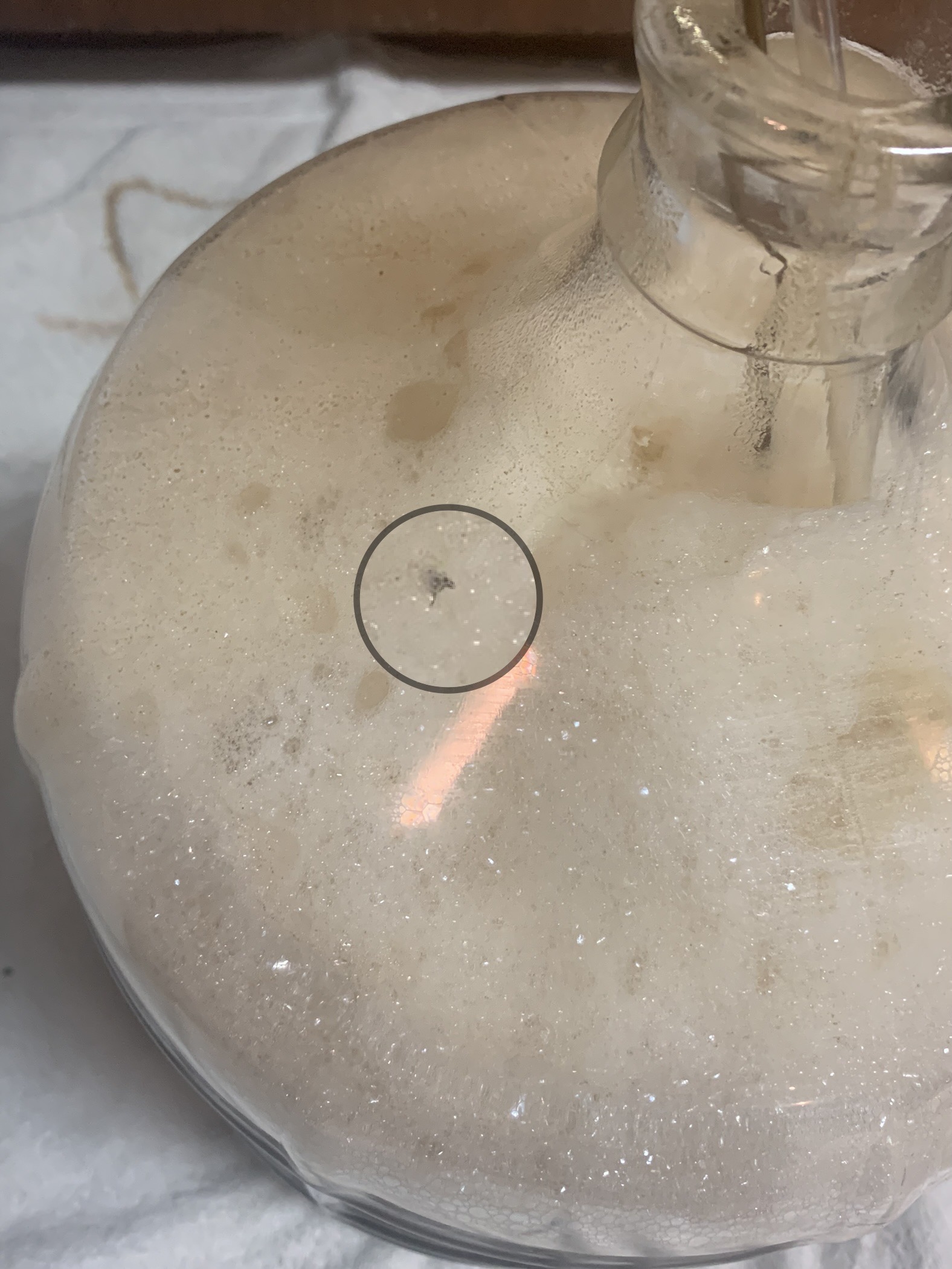

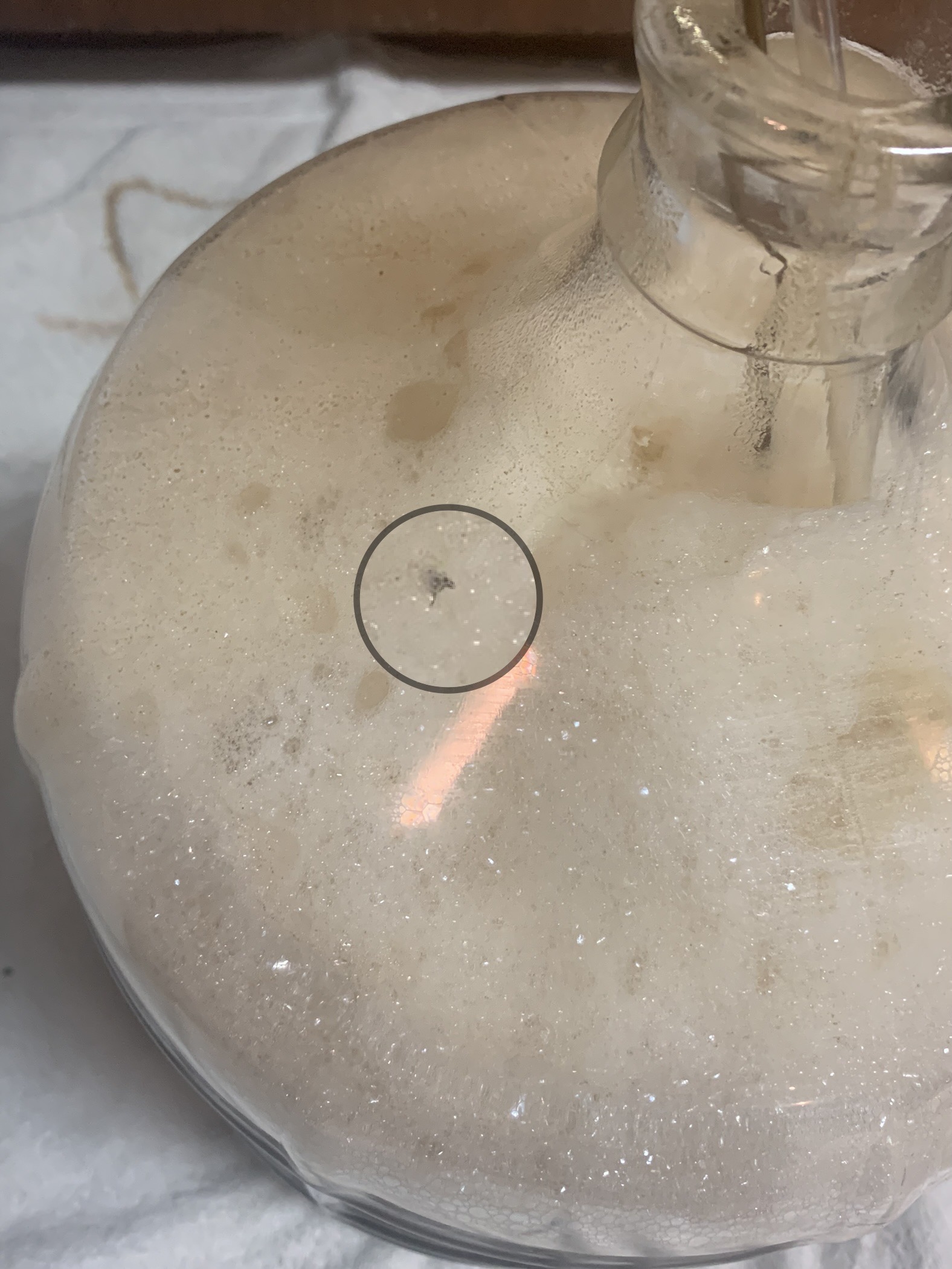

Pitch yeast and see a fruit fly swimming in the foam from aerating the wort

ncbrewer

Well-Known Member

You've got to tell us - what did you do?Pitch yeast and see a fruit fly swimming in the foam from aerating the wort View attachment 831346

I guess you made a fruity beer then.

Don't double-check the level of vodka in your airlock, not noticing that there was suck-back when it cooled to fermentation temperature. Don't get concerned about the lack of bubbles, because sometimes that doesn't happen when we're watching. Don't worry about the beautiful smell of fermentation that filled the garage, because that's what's supposed to happen. DO notice the beer was open to the atmosphere for a week and a half.

- Joined

- Feb 16, 2012

- Messages

- 3,356

- Reaction score

- 4,230

- Location

- Either in the brewery or on the road

Not a problem. It's all protein. The alcohol will sanitize it, after it's killed the little bugger. Look on the bright side: he'll die happy.Pitch yeast and see a fruit fly swimming in the foam from aerating the wort View attachment 831346

It's probably doesn't matter anymore, but have you tried to retrieve it?Pitch yeast and see a fruit fly swimming in the foam from aerating the wort

I would probably use a bendable metal wire with a small fabric pad on the end.

Once the yeast is established and fermenting away, the acetobacter on the fruit fly may not have much chance in that environment.

Similar threads

- Replies

- 2

- Views

- 402

- Replies

- 7

- Views

- 671

- Replies

- 4

- Views

- 406

- Replies

- 3

- Views

- 531