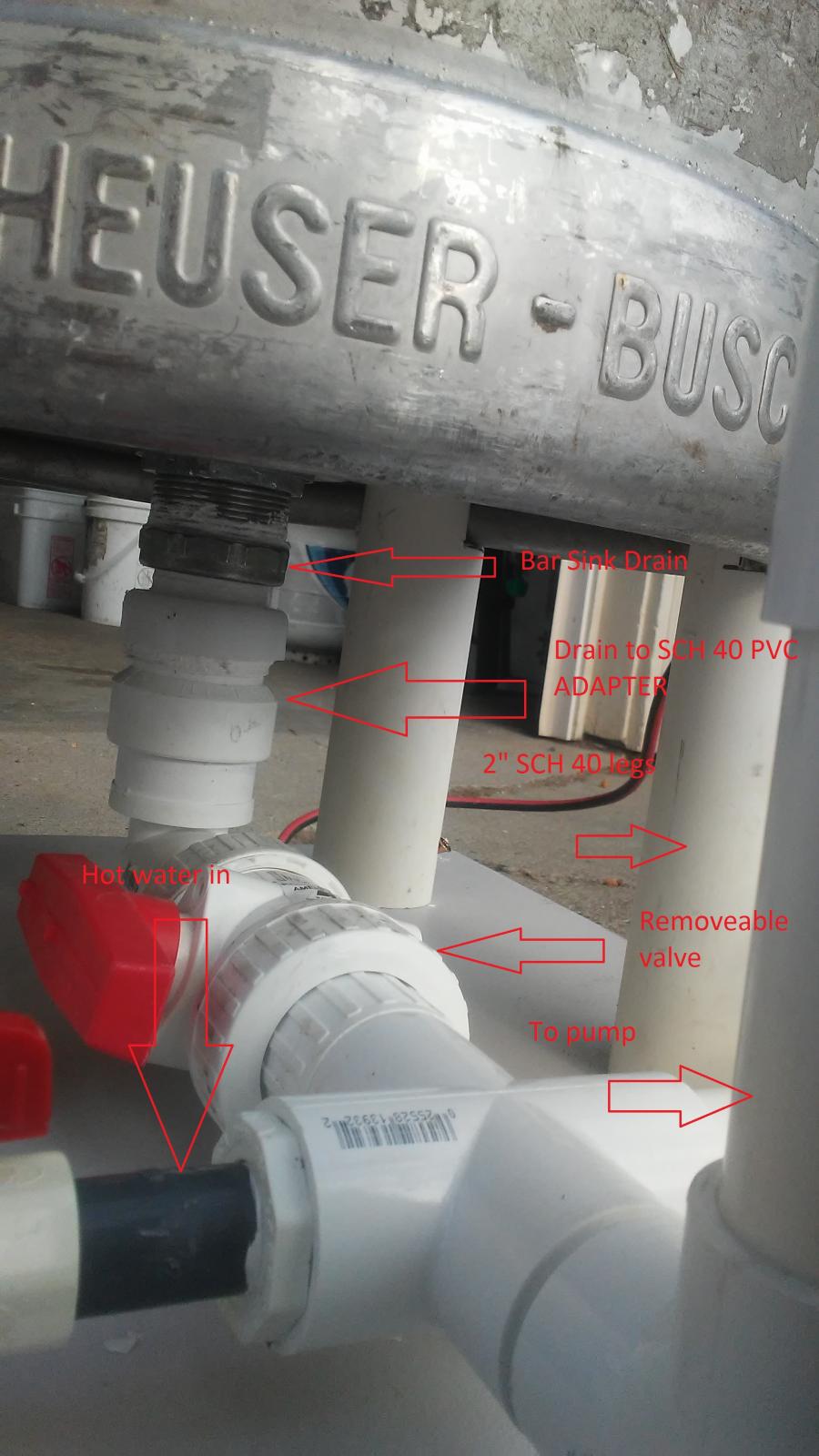

Hi all! After spending years working in a craft brewery I decided it was time for a career change and I'm excited for brewing to become a hobby again. That being said, I'm not willing to give up CIP. I've built some rudimentary ones in the past, but I'm doing it right this time with a proper rotating spray ball and a centrifugal pump.

I'll post some photos of my build as I get started, but I wanted to share a great deal on a pump for this.

http://www.ebay.com/itm/122452058335

While most utility/sump pumps kind of sketch me out with oil leakage, overheating, and mysterious plastics and seals, this one seemed like the ideal pump. Normally it's pretty cost-prohibitive for us homebrewers (retails for $800), but at $200 it's cheaper than a Chugger Max, and a good bit more powerful too!

I looked up the specs and it's chemical resistant and handles liquid up to 200 degrees. At 3/4 hp it should have enough wallop to spin a spray ball inside a corny keg. I wouldn't recommend this as a brewhouse pump, but who the heck needs to pump wort around their garage at 45 gpm anyway?

Sorry for the long winded explanation, but I'm excited to try this pump and wanted some other brewers to get a good deal too. More to come. Cheers!

I'll post some photos of my build as I get started, but I wanted to share a great deal on a pump for this.

http://www.ebay.com/itm/122452058335

While most utility/sump pumps kind of sketch me out with oil leakage, overheating, and mysterious plastics and seals, this one seemed like the ideal pump. Normally it's pretty cost-prohibitive for us homebrewers (retails for $800), but at $200 it's cheaper than a Chugger Max, and a good bit more powerful too!

I looked up the specs and it's chemical resistant and handles liquid up to 200 degrees. At 3/4 hp it should have enough wallop to spin a spray ball inside a corny keg. I wouldn't recommend this as a brewhouse pump, but who the heck needs to pump wort around their garage at 45 gpm anyway?

Sorry for the long winded explanation, but I'm excited to try this pump and wanted some other brewers to get a good deal too. More to come. Cheers!