CrystalShip

Well-Known Member

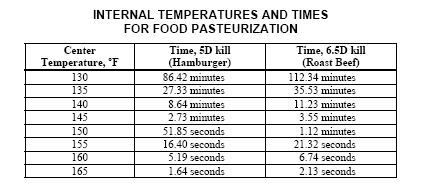

Everyone knows the commonly accepted practice is to add your immersion chiller during the last 15min of the boil in order to sanitize it....but why? From all of the research I have gathered, it only takes about 30seconds of immersion in a liquid of 170 degrees or more to sanitize something. I have been doing the boiling method for years without questioning the practice, but I have a 50ft chiller and it totally kills the boil for a minute or two....which is really annoying.

why not just add it at flameout?

thoughts?

why not just add it at flameout?

thoughts?