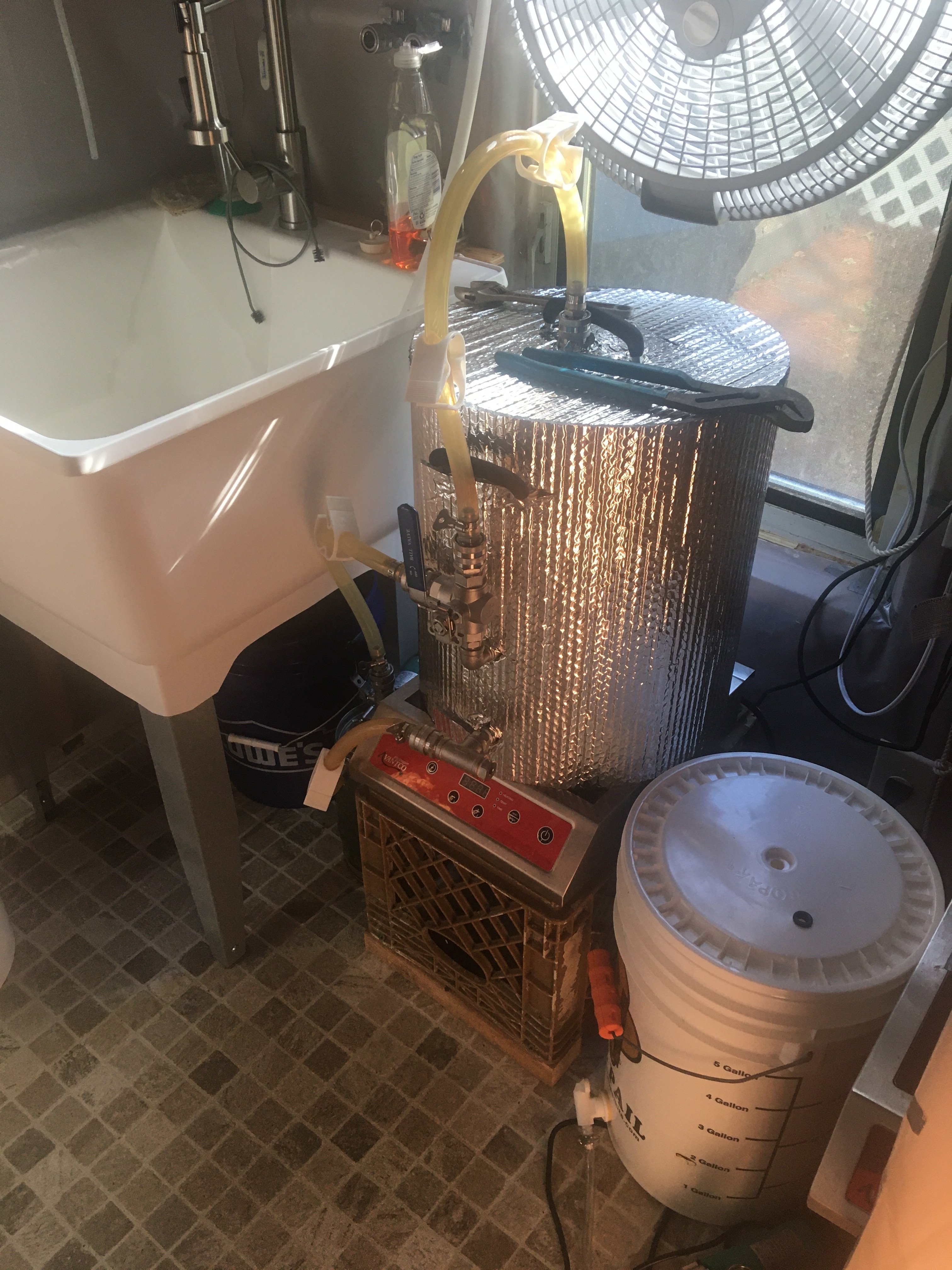

I would love some equipment design help to improve my mash temp control. Here’s a little about where I’m starting: I have a Spike 10 gallon kettle with two welded ports (outlet and whirlpool) on an Avantco IC3500 induction plate where I BIAB. I have a pump to recirculate at mash (really most of the time), whirlpool, etc. To maintain mash temp, I have to babysit it for an hour switching between 500W (too low), and 700W (too high). I really want to avoid this and I see a few options to do so:

1. Build a RIMS which I *just* learned about here: Heat Stick in T-fitting? My main concern is accidental scorching if I screw something up.

2. Install a 120V element into the kettle to augment the induction plate. Will it disrupt my whirlpool? Will it melt my bag? It is a PITA to clean? Drilling into my lovely kettle is scary and I don’t want to trade one inconvenience for another. On the other hand, it might be a nice backup in case my induction plate ever dies (I lost one already). Plus, it’ll help get me up to boiling in no time. I also like that it keeps everything compact in my tiny brew space.

3. Stop being so precious about my mash temps and just insulate the hell out of it, letting it drop a little.

1. Build a RIMS which I *just* learned about here: Heat Stick in T-fitting? My main concern is accidental scorching if I screw something up.

2. Install a 120V element into the kettle to augment the induction plate. Will it disrupt my whirlpool? Will it melt my bag? It is a PITA to clean? Drilling into my lovely kettle is scary and I don’t want to trade one inconvenience for another. On the other hand, it might be a nice backup in case my induction plate ever dies (I lost one already). Plus, it’ll help get me up to boiling in no time. I also like that it keeps everything compact in my tiny brew space.

3. Stop being so precious about my mash temps and just insulate the hell out of it, letting it drop a little.