Guys,

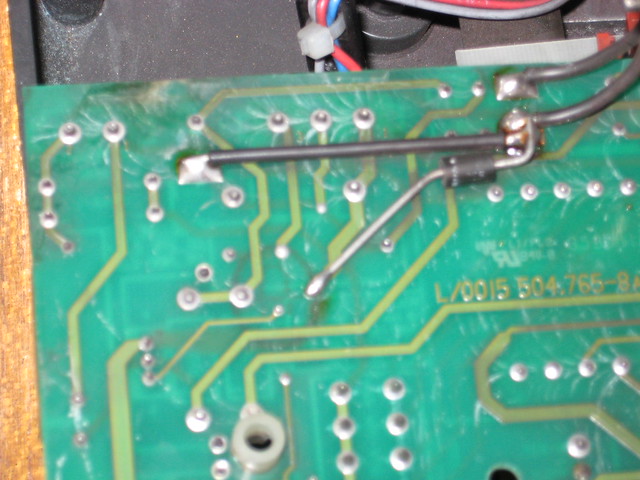

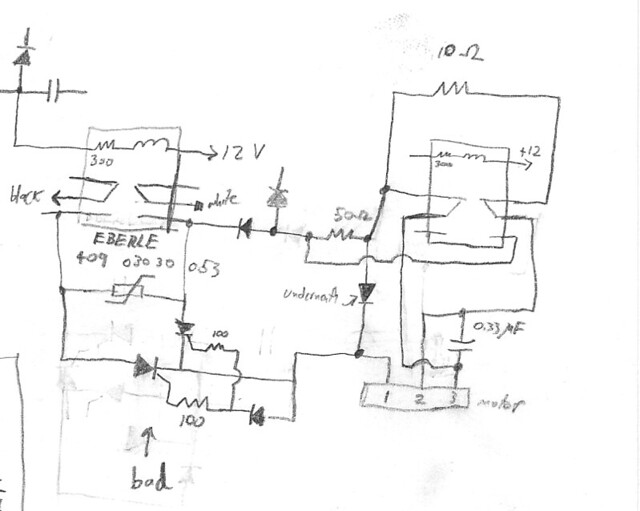

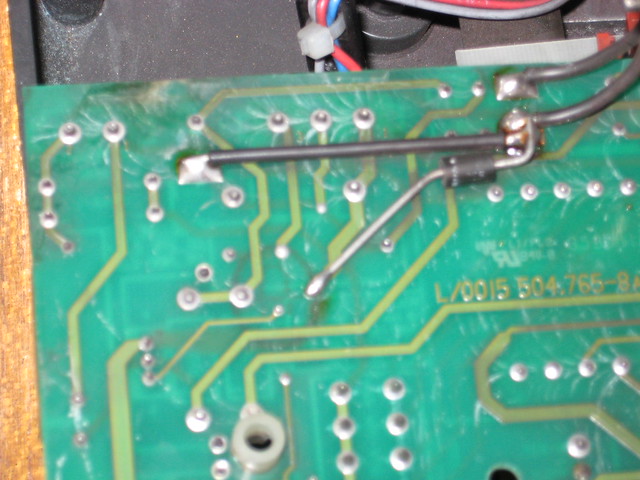

I picked up a centrifuge that had been discarded since it was blowing fuses. I have spent the last few days reverse engineering the schematic, but as I look at the under side of the PCB, I can see white marks on the surface connecting some of the solder points and traces. Is this evidence of arcing?

I am wondering, because the white arcs are only on the high-voltage AC components like the transformer, motor relays, etc, and because the white marks have a very distinctive and consistent curvature to them. Also, there is A LOT of iron dust inside the centrifuge (from the wearing-down of the motor brushes and commutator I presume) including on the PCB and the piece of plastic that the PCB was resting on (so much dust that my hands are black after working on this thing), so that makes me suspicious of arcing also.

I only have 2 more fuses to blow for this thing, so before I just clean the hell out of everything and hook it up again, I wanted to see if anyone could tell me if this is arcing or not. Thanks!

I picked up a centrifuge that had been discarded since it was blowing fuses. I have spent the last few days reverse engineering the schematic, but as I look at the under side of the PCB, I can see white marks on the surface connecting some of the solder points and traces. Is this evidence of arcing?

I am wondering, because the white arcs are only on the high-voltage AC components like the transformer, motor relays, etc, and because the white marks have a very distinctive and consistent curvature to them. Also, there is A LOT of iron dust inside the centrifuge (from the wearing-down of the motor brushes and commutator I presume) including on the PCB and the piece of plastic that the PCB was resting on (so much dust that my hands are black after working on this thing), so that makes me suspicious of arcing also.

I only have 2 more fuses to blow for this thing, so before I just clean the hell out of everything and hook it up again, I wanted to see if anyone could tell me if this is arcing or not. Thanks!