Hi,

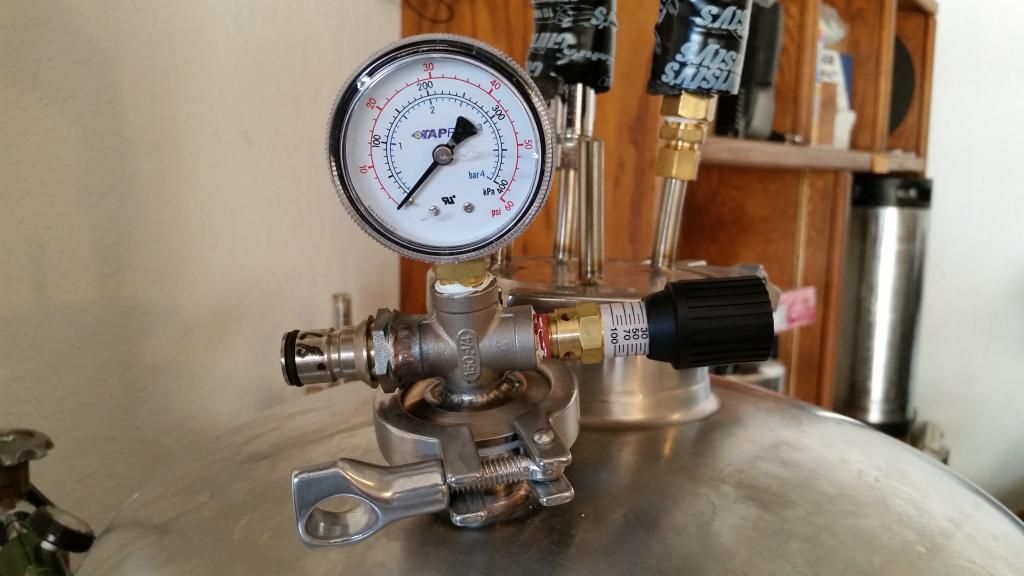

I'm looking to make a Spunding valve but can't seem to find a good adjustable pressure relief valve. All the ones I've come across have bad reviews (either they leak or don't reset to the correct pressure)

What have you used successfully?

Thanks!

I'm looking to make a Spunding valve but can't seem to find a good adjustable pressure relief valve. All the ones I've come across have bad reviews (either they leak or don't reset to the correct pressure)

What have you used successfully?

Thanks!