First time brewing 2 months ago and I dived in head first. All-grain SMaSH 10 lbs 2-row and 6 oz Cascade with my own never-been-tested recipe. I didn’t have a mash-tun or a BIAB so I just poured the grain into some cheesecloth, tied it up, and steeped it for an hour in some hot water (around 165f). Sparged with a few gallons of even hotter water and then brought her to a boil. Added some hops, boiled for an hour, chilled, racked, and pitched yeast.

OG- 1.032

FG- 1.008

Hazy, astringent, bitter, gross.

Still determined to get it right I tried again. This time I bought a BIAB.

Same result but a bit better efficiency with an OG of 1.042.

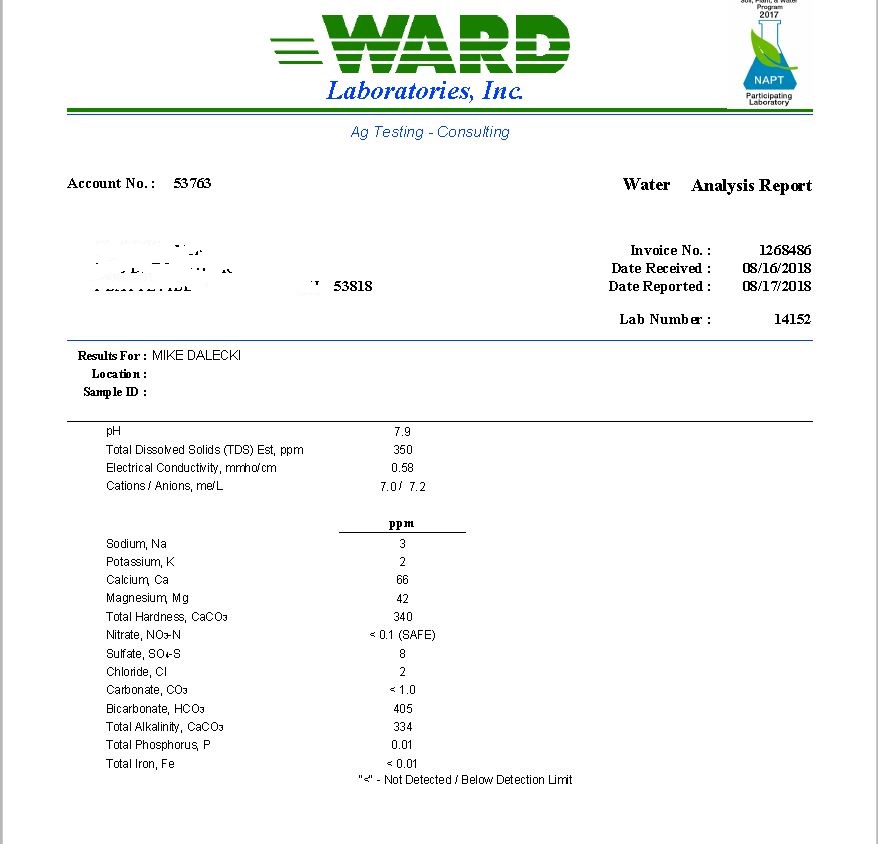

Research revealed the culprit. I am on a well and have been brewing with a pH of 8+

About 4 doses of 5.2 stabilizer made a dramatic difference. OG of 1.050 with only 8.5 lbs 2-row and the beer was crystal clear (clear anyway), and delightful. Different recipe btw. It’s supposed to be that color.

So, apparently, water chemistry really does matter.

OG- 1.032

FG- 1.008

Hazy, astringent, bitter, gross.

Still determined to get it right I tried again. This time I bought a BIAB.

Same result but a bit better efficiency with an OG of 1.042.

Research revealed the culprit. I am on a well and have been brewing with a pH of 8+

About 4 doses of 5.2 stabilizer made a dramatic difference. OG of 1.050 with only 8.5 lbs 2-row and the beer was crystal clear (clear anyway), and delightful. Different recipe btw. It’s supposed to be that color.

So, apparently, water chemistry really does matter.