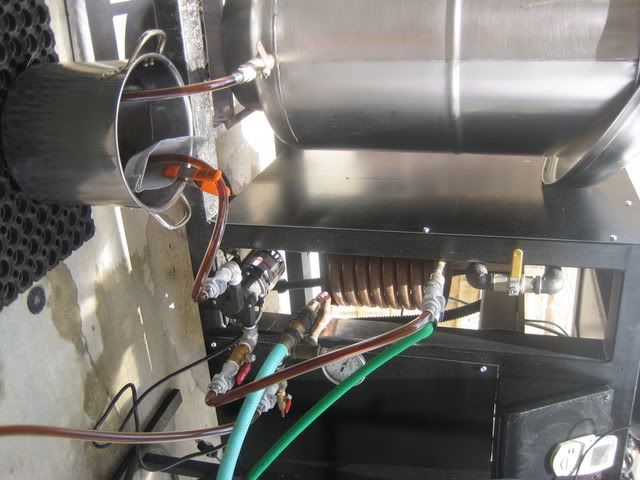

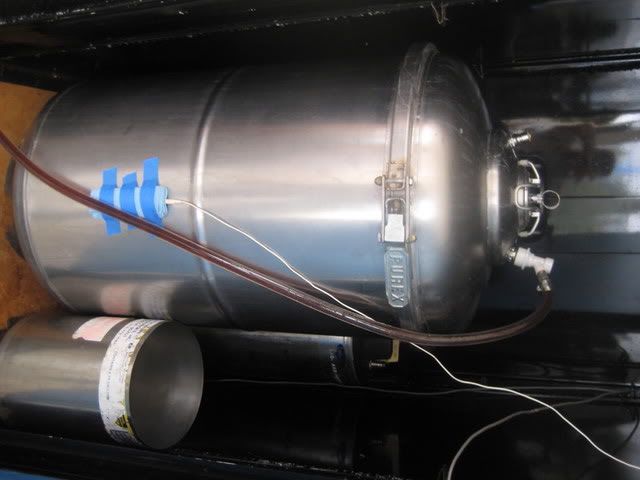

Well this weekend I brewed a 10 gal batch of APA and just bought a thermo that I can drop in the carboy to monitor the temp of the wort coming out of the chiller and I was surprised and pissed to see that it was at 80'F even after using a 20' 3/8" OD pre chiller in an ice bath and using a 30' CFC using the same size copper. The ambient temp was somewhere around 93'F and I actually kept all of the chilling equipment inside to make sure the copper didn't heat up past 70'F. I did a recirc back into the kettle and within about 7-8 minutes had the wort from 212'F to right at 140'F which I was very happy with, but past that it dropped very slowly with diminishing thermal exchange. After it hit about 125'F I went ahead and started pumping it into the carboy.

One thing that I do not have implemented on my system is a ball valve on the output side of my march pump that would allow me to slow the flow of wort and allow it more time within the CFC to cool down and one thing that I could not do at the time was check the temperature of the out side of the pre chiller but just by grabbing the output side line I could tell it was doing a pretty decent job of chilling the tap water down.

My question for you guys is this, what changes would you make to my system? I am thinking a ball valve is an essential part of the equation on the output side of the march pump to slow the wort flow but could I also look into getting some type of aquarium pump to actually pump ice cold water out of a bucket with instead of using the tap water? Do any of you guys use a setup that uses a source of ice water to pump through? If I just need to put a ball valve on and beef up the pre chiller to say maybe 50', I can do that pretty easily but I am wondering how much of a difference you guys think it would make.

One thing that I do not have implemented on my system is a ball valve on the output side of my march pump that would allow me to slow the flow of wort and allow it more time within the CFC to cool down and one thing that I could not do at the time was check the temperature of the out side of the pre chiller but just by grabbing the output side line I could tell it was doing a pretty decent job of chilling the tap water down.

My question for you guys is this, what changes would you make to my system? I am thinking a ball valve is an essential part of the equation on the output side of the march pump to slow the wort flow but could I also look into getting some type of aquarium pump to actually pump ice cold water out of a bucket with instead of using the tap water? Do any of you guys use a setup that uses a source of ice water to pump through? If I just need to put a ball valve on and beef up the pre chiller to say maybe 50', I can do that pretty easily but I am wondering how much of a difference you guys think it would make.