And when run at refrigerator temperatures the coils will rust and leak brown gunk all over your kegs. At least an older model did when I tried to use it as a bottle fridge

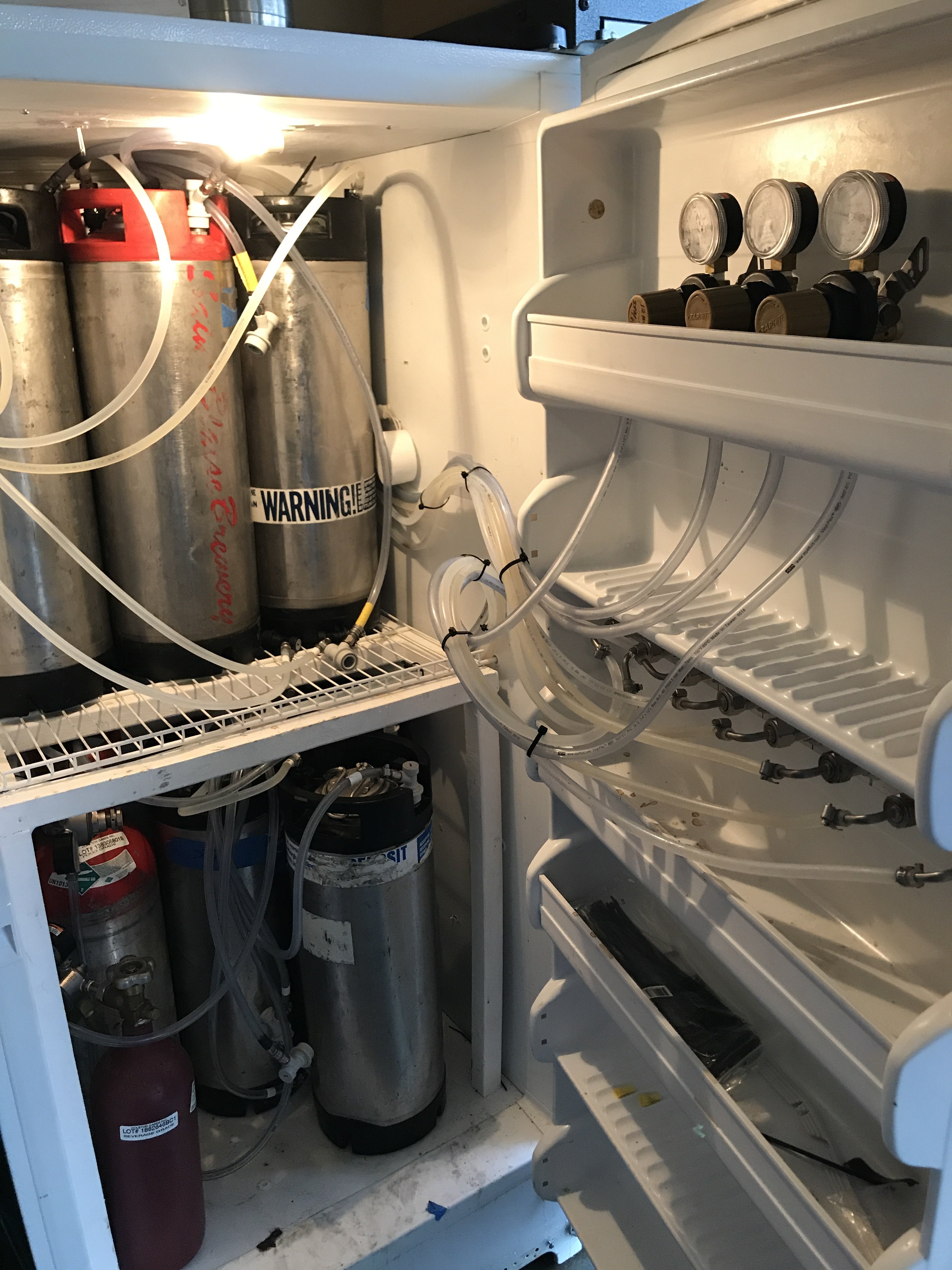

None of the models being used here have internal coils around the shelves. These are frost free models where the coils are in the walls. Sounds like you had a condensation problem that caused your rusting.