My fellow brewers,

I've scoured the forum for a little while now and though I've found many answers to a handful of questions regarding my latest brew, I'm curious to hear what your thoughts are on a little issue I have with cracked plastic carboy caps and long periods of fermentation.

I bottled an ale tonight after 50+ days in primary. The plastic carboy caps for mounting airlocks seem to sprout cracks stemming from the center hole after only 2-3 uses. This batch in particular really split it open (see picture) and thus has left my fermenting beer exposed to the climate that is the innards of my kitchen cabinet. For what length of time I'm not sure, but all seems well.

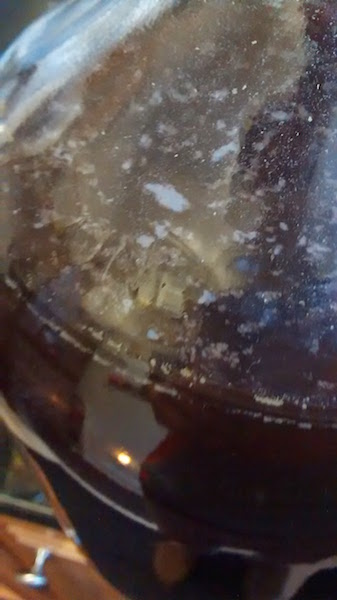

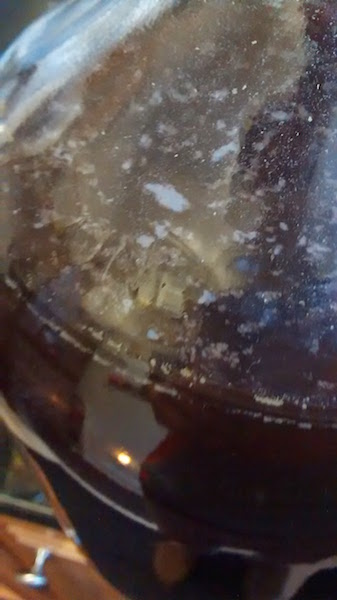

My FG turned out A-OK, reaching a comfortable low of 1.014. The aroma and flavor had a tinge I would liken to cider, though there is pumpkin, maple and spices in this brew that would influence notes of sweetness. The only visible concern I have are the patches of white "stuffs" that coagulated on top of the liquid while in the carboy (see other picture).

I understand a crack in the plastic cap is nothing to worry about- CO2 dominates the fight against intrusive contaminants, sure. BUT, after fifty days in primary, even if the yeast did all its work in time before the crack grew, would there be anything that could drastically affect my yet-to-be-bottle-conditioned beer?

Please, share your knowledge about the strength of a well-fermented beer and/or the weaknesses of a static batch that hasn't seen action in days (or weeks).

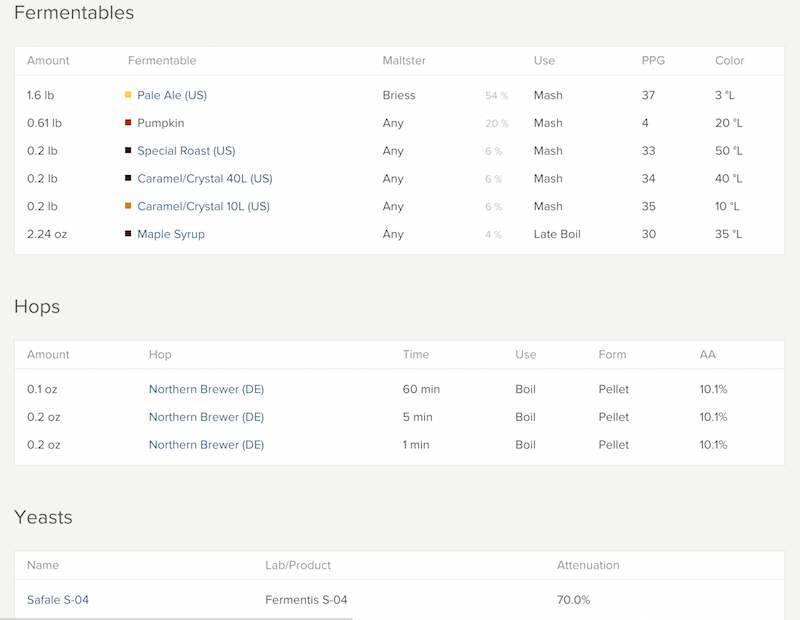

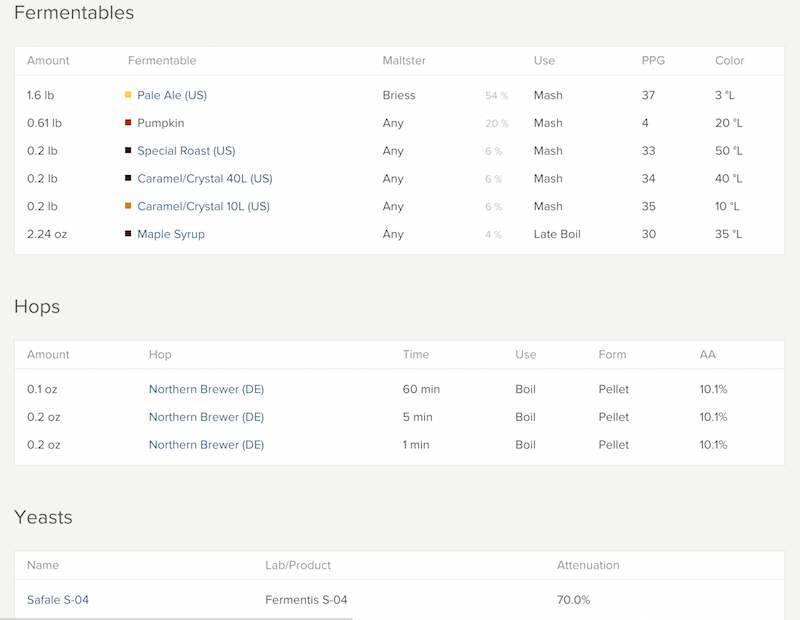

Recipe notes:

The screen cap is missing the pinch of Irish moss I used. 75 minute mash, 60 minute boil. Minimal time in an ice bath, relatively smooth transfer with an auto-siphon (still not sure how I feel about this tool). Fermented at temperatures ranging from 65-80 degrees. Primed for bottle-conditioning with maple syrup.

I've scoured the forum for a little while now and though I've found many answers to a handful of questions regarding my latest brew, I'm curious to hear what your thoughts are on a little issue I have with cracked plastic carboy caps and long periods of fermentation.

I bottled an ale tonight after 50+ days in primary. The plastic carboy caps for mounting airlocks seem to sprout cracks stemming from the center hole after only 2-3 uses. This batch in particular really split it open (see picture) and thus has left my fermenting beer exposed to the climate that is the innards of my kitchen cabinet. For what length of time I'm not sure, but all seems well.

My FG turned out A-OK, reaching a comfortable low of 1.014. The aroma and flavor had a tinge I would liken to cider, though there is pumpkin, maple and spices in this brew that would influence notes of sweetness. The only visible concern I have are the patches of white "stuffs" that coagulated on top of the liquid while in the carboy (see other picture).

I understand a crack in the plastic cap is nothing to worry about- CO2 dominates the fight against intrusive contaminants, sure. BUT, after fifty days in primary, even if the yeast did all its work in time before the crack grew, would there be anything that could drastically affect my yet-to-be-bottle-conditioned beer?

Please, share your knowledge about the strength of a well-fermented beer and/or the weaknesses of a static batch that hasn't seen action in days (or weeks).

Recipe notes:

The screen cap is missing the pinch of Irish moss I used. 75 minute mash, 60 minute boil. Minimal time in an ice bath, relatively smooth transfer with an auto-siphon (still not sure how I feel about this tool). Fermented at temperatures ranging from 65-80 degrees. Primed for bottle-conditioning with maple syrup.