Every time I use a strike water calculator it shows I should be at 160ish. My question is after the grain goes in what temp should I maintain the water at. Should I maintain the strike water temp or go lower, because I've read anything above 158 will not covert all the sugar.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Strike water

- Thread starter mudog

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

BrewnWKopperKat

ʘ‿ʘ

After the grains goes in, maintain the mash temperature.My question is after the grain goes in what temp should I maintain the water at.

Your strike water temperature depends on several factors:Every time I use a strike water calculator it shows I should be at 160ish.

- your intended mash temp

- the amount of grain

- the temperature of your grain

- the amount of strike water

- temp losses incurred due to pouring into a cold or preheated mash vessel

- temp losses due to stirring while the lid is off

Brew365

Due to 5. and 6. and because I don't preheat the mash tun (converted cooler), I need to add 12-14 degrees F (!) to my calculated strike water temp to come out exactly (or up to 2 degrees high) at my mash temp after stirring and putting on the lid. When I check 3-5 minutes later, when everything has stabilized, it's pretty much spot on. If still a degree (or 2) high, I may stir for another 20-30 seconds and lose enough heat that way. Or just let it ride.

It's much easier to lose some excess heat (add cold water, stir, or both) than try to increase it in a mash tun that's not (in)directly heated.

McKnuckle

Well-Known Member

The strike water temp is chosen so that when you mix the water with your milled grains, the resulting mash will be at your desired mash temperature. The initial mash temp is always lower than the strike temp, because the grains are cooler than the strike water, and mixing them in cools the mixture down.

At that point, the basic instruction is to maintain the desired mash temperature. The water strike temp has served its purpose and is no longer relevant.

At that point, the basic instruction is to maintain the desired mash temperature. The water strike temp has served its purpose and is no longer relevant.

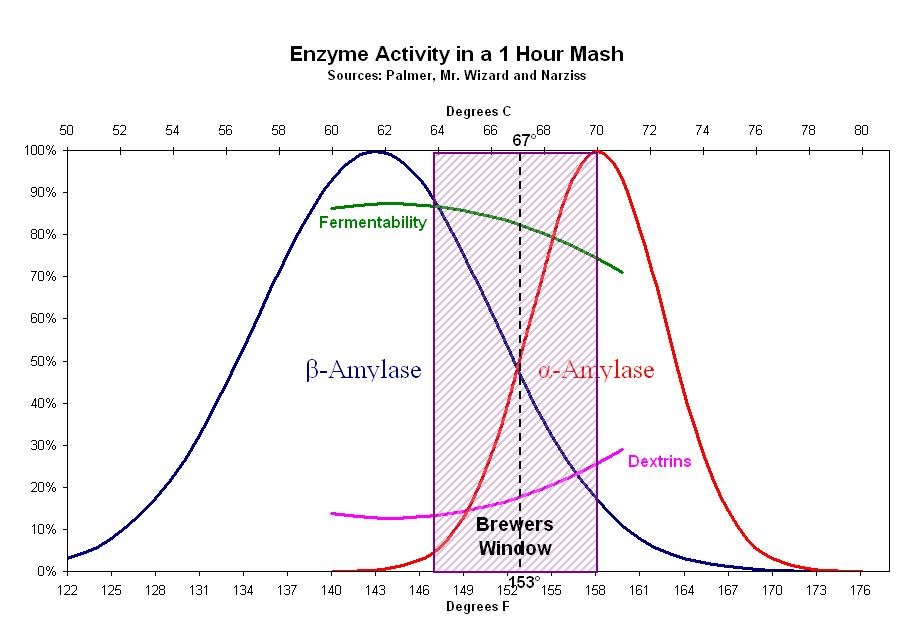

you want to maintaine the mash at between 145-158f, depending how much attenuation you want the beer to get. lower more fermentable, higher less fermentable. there are two main enzymes at work...beta-amylase likes it closer to 145f, and alpha-amylase works better at closer to 162f...but alpha doesn't cleave starch small enough for yeast to eat, so a compromise is made...

i know this isn't quite the answer you were looking for. strike water will cool, when grains are added, (unless they came out of the oven, lol)

When you add the strike water it will lose heat because it will heat up the grains and also the mash tun. Everyone is different, and it also will be different depending on the temperature of your grains, amount of water, and the mash tun. I will bring my Mash tun and grains indoors for 24 hours before brewing to get a consistent temperature.

You want the mash temp to be somewhere in the region of 148 to 155 F for most beers. I target around 148 - 150 F. My strike temperature (water going into the mash tun) is 163 F for my system.

You want the mash temp to be somewhere in the region of 148 to 155 F for most beers. I target around 148 - 150 F. My strike temperature (water going into the mash tun) is 163 F for my system.

Also keep in mind your environment. You shouldn't have too much of a swing, but for example I have to account for different temp losses when i'm brewing (outdoors) in August (90°F) versus February (-10°F).

- temp losses incurred due to pouring into a cold or preheated mash vessel

- temp losses due to stirring while the lid is off

Thanks!Also keep in mind your environment. You shouldn't have too much of a swing, but for example I have to account for different temp losses when i'm brewing (outdoors) in August (90°F) versus February (-10°F).

I knew I forgot a big one!

I was deep frying in gusty, sub-zero weather in a foot of snow. I could not get that pot to 375F until after I set up a windscreen.

Similar threads

- Replies

- 14

- Views

- 1K

- Replies

- 1

- Views

- 620

- Replies

- 39

- Views

- 2K