CGVT

Senior Member

I just checked this thread to see if someone made the obligatory "That's what she said" post.

You all disappoint me.

*sigh*

You all disappoint me.

*sigh*

Last edited:

smelly, don't hate me but 0.8 bar? i dont' understand this

so weird, the calculator i'm using says that 5ft of line should be 7 or 8psi. but you're saying that 5ft (150cm) is fine with .8bar or 11ishpsi

in any case. I am going to lower the psi and burp my keg a couple times. Good?

I have to disagree with a few things. First of all, you don't set your psi based on the length of your lines; you make your lines the length needed to balance your system based on the temperature and the psi on your regulator.

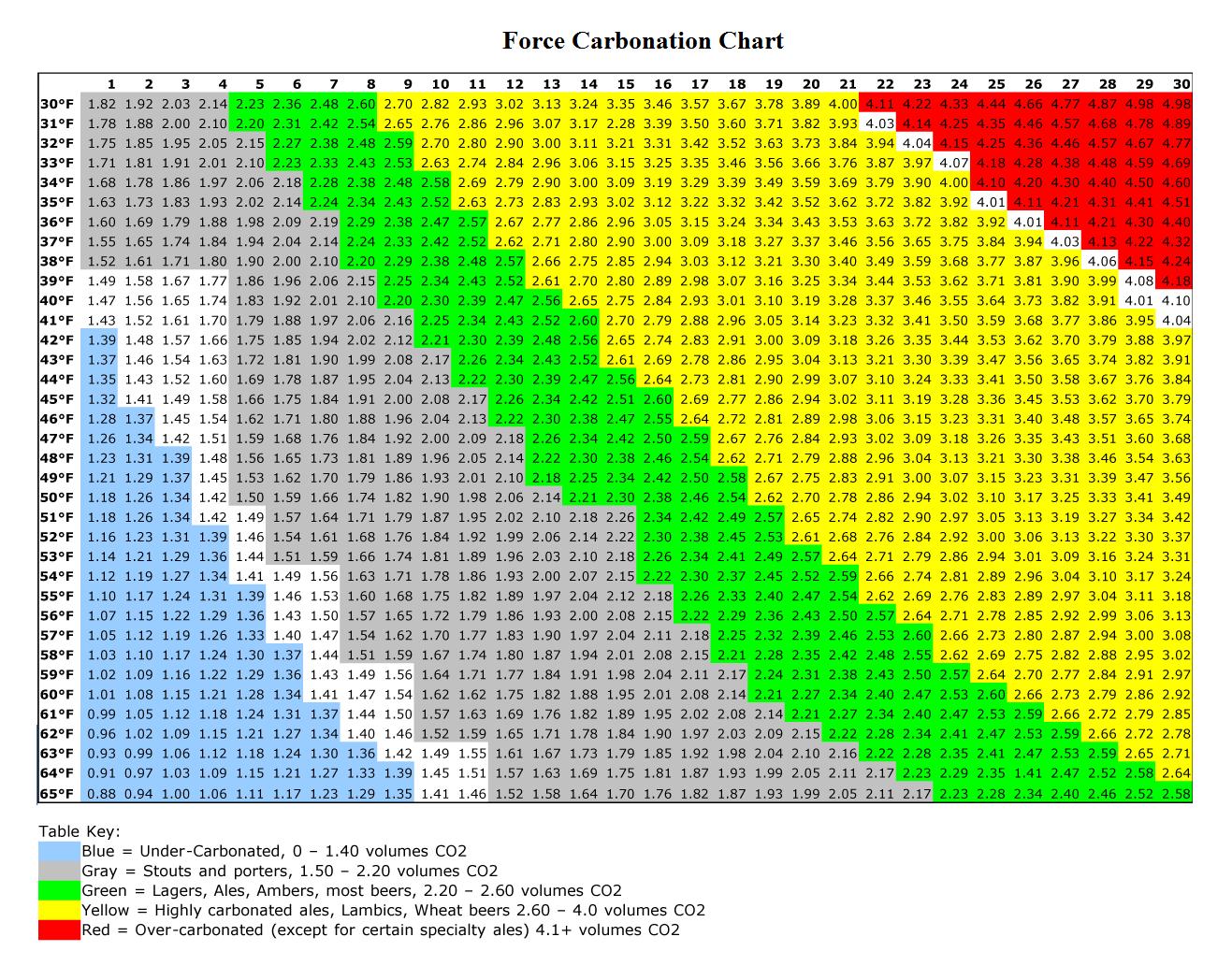

For example, I use this carbonation chart:

View attachment 574966

My fridge is 40 degrees, and I like 2.5 volumes of c02 in my beers (for most American styles and lagers, anyway). So I need to set my regulator at 12 psi.

Five foot long beer lines would be WAY too short to serve that. So I have 12' lines in my kegerator, to balance that amount of carbonation.

It doesn't help that your tower is warmer, and allowing the beer to foam there. But while smelly has good results with 5' lines, most people do not. Most people who want properly carbonated beer find that 1 foot of line per 1 psi on the regulator is often the sweet spot for a proper carb level, without foaming or too much restrictions.

If you turn down your psi to compensate for your short lines, your beer will be undercarbed. There really isn't any downside to long lines- it just takes a few seconds longer to pour a beer- but short lines mean headaches often, especially if you want to serve a highly carbed beer like a weizen or other beers.

Pick the level of carb you want (most people like 2.4-2.6 for most standard ales), and set your regulator based on the temperature of your kegerator and that carb level. Then fix your issues, like the improper serving lines (they should be pretty thick walled beer lines), and the short length.

I really don't think it's the tower warming- if it was, the first pour would be foamy but the rest would be better since the tower would cool from the pours. Your issue seems to be the reverse- the beer in the lines comes out fine for the first pour, but further pours are allowing the c02 to break out of solutions.

Enter your email address to join: