I figured the distilling forum was as good a place as any for this. I got this toy for making essential oils from various stuff. Today, hops. Still in the process. Biomass flask contains 4 oz of citra.

I'm not sure how to use the oil. In fact, I'm not fully sure what I'm doing here. But having fun anyway.

What's going on?

I'm not sure how to use the oil. In fact, I'm not fully sure what I'm doing here. But having fun anyway.

What's going on?

- boil flask (RODI water) creates steam

- steam rises through the biomass flask (hops here)

- steam enters the still head where it starts to condense; note it's slanted slightly downward

- graham condenser completes the condensing of the steam to liquid; the condensed steam drips down that curly glass tubing in the middle. Chlled water is passing around it, from bottom to top (see rubber tubing to small submersible fountain pump in HD bucket). It's basically a counterflow chiller.

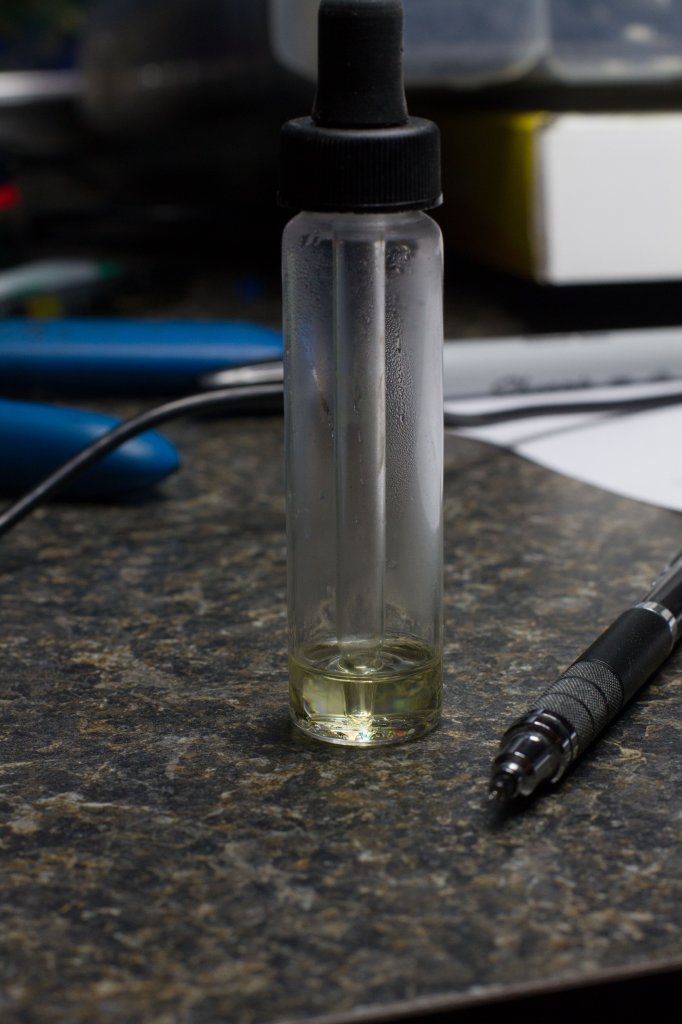

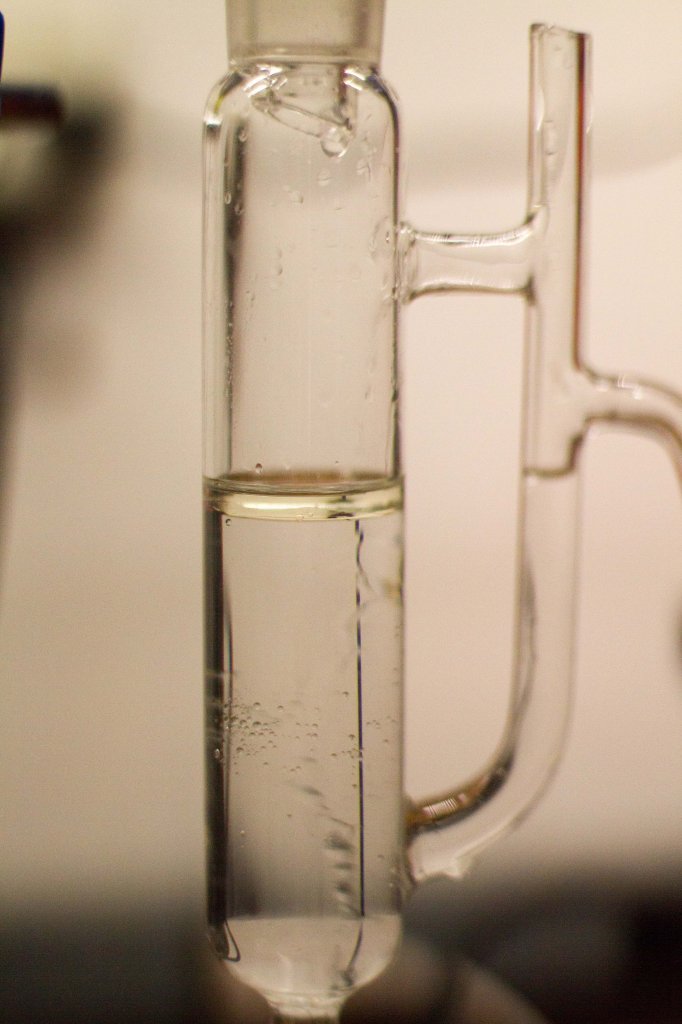

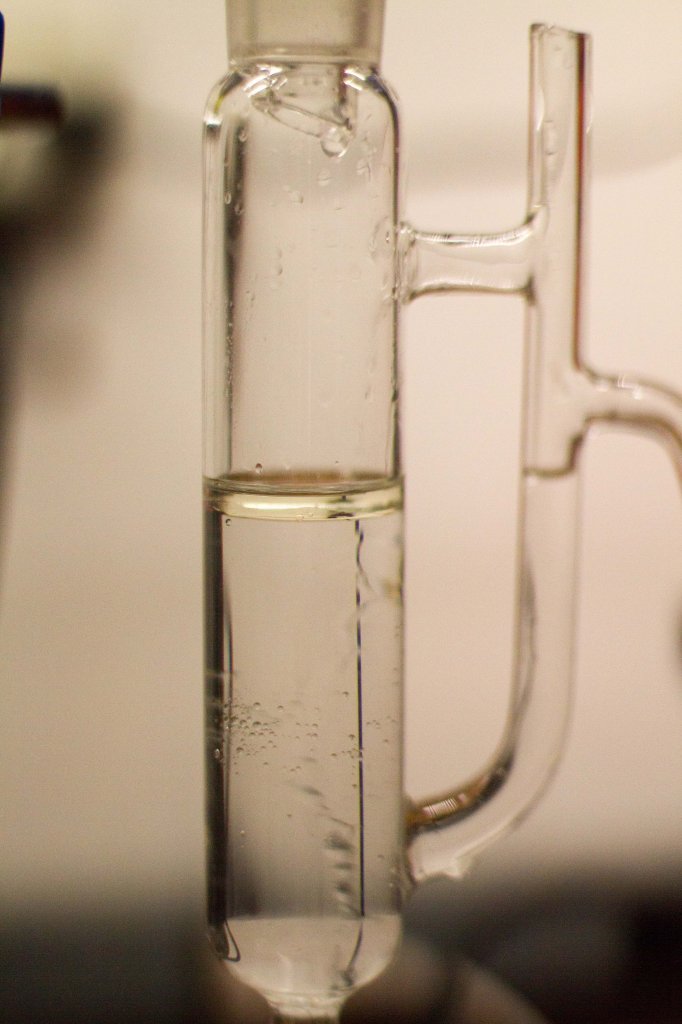

- separatory trap captures the oil, floating on top of water. See second picture, yellow hop oil floating on column of water. It's designed so that if it fills, the water will overflow out the side tube and you don't lose any oil. The stopcock allows you, in the end, to drain the water, then drain the oil into a vial.

Last edited: