alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

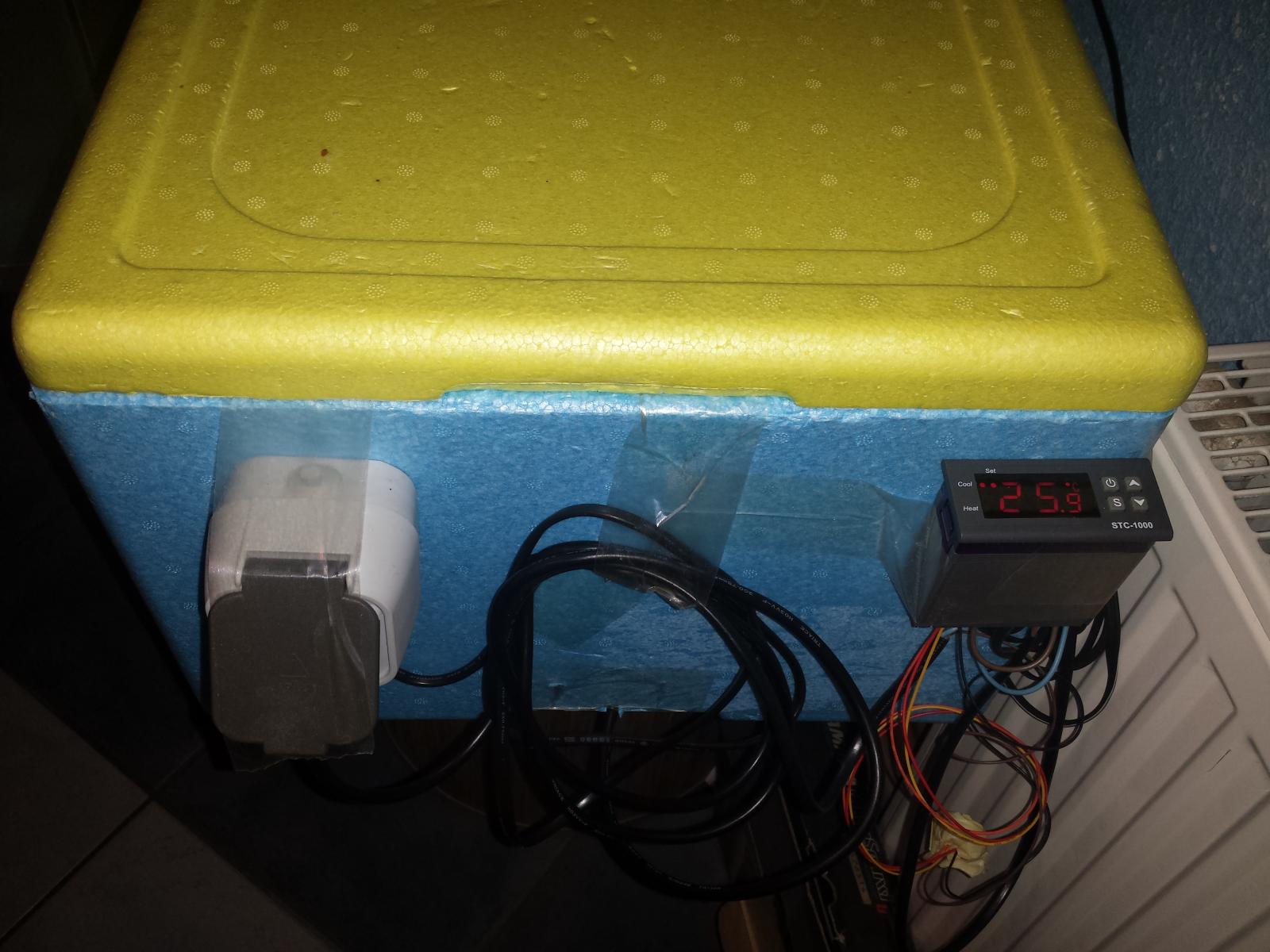

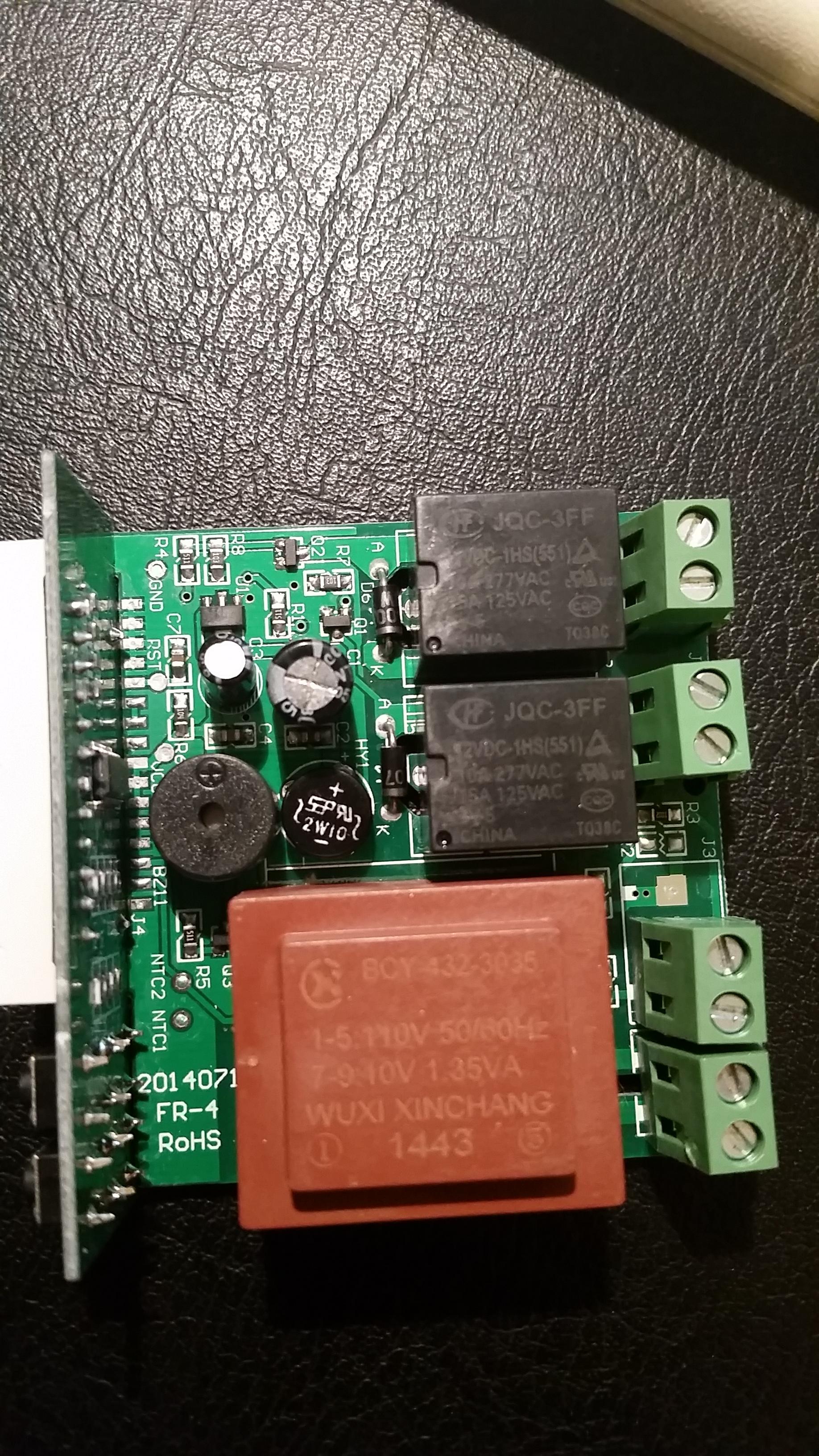

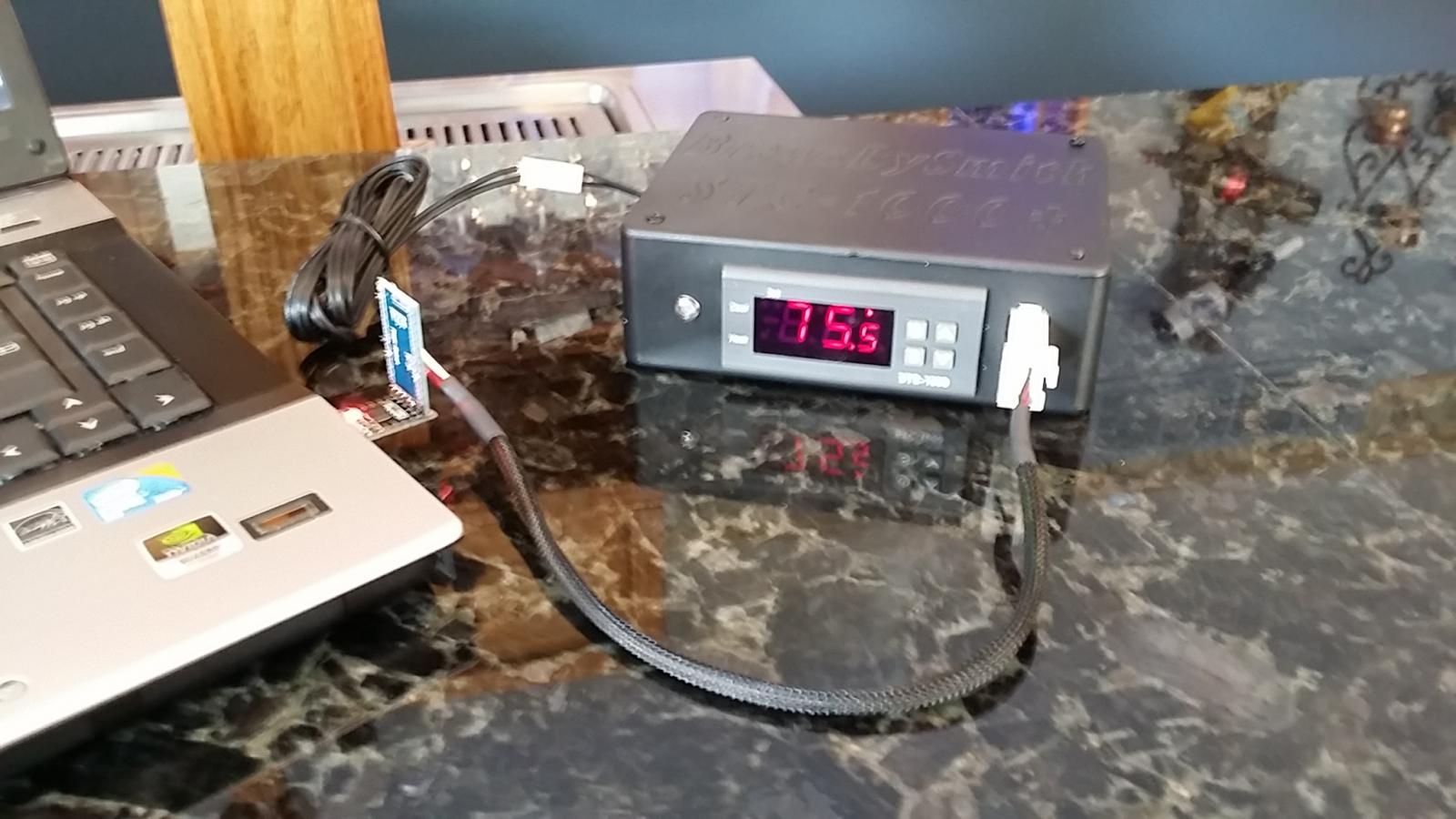

Done some real testing. Here is the setup:

Here is the result:

Datafile:

https://dl.dropboxusercontent.com/u/9236068/Pr0.txt

There is a bug in first level. As you can see the ramp of 50C is ignored. Try this twise just to make sure.

Else; Work great. With less filtering the and faster response it is perfect.

I use

hy=0.1

cd=0

hd=0

rP=0

I calibrate temp at aprox 15C (tc=+0.4C) and notised that i need anoter 0.4C when temp is higher, at aprox 70C. Maby the temp scale is not linear?

Great job Mats!!

Hi!

That curve looks ok to me. It seems it takes you pretty much exactly 20 minutes to reach 50C, so it moves on to 65C pretty much exactly by the time you get there. Which would be the correct behaviour.

And yes, the temperature-resistance curve of the NTC is very non-linear. So if you need to calibrate around your working temperature.